Method for assisting braze welding through activation of surface of SiO2 ceramic matrix composite material

A composite material and surface activation technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as difficult to achieve high-quality connection of composite components, poor wettability of active solder, and influence on the mechanical properties of joints , to achieve the effect of facilitating industrial production, improving connection quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

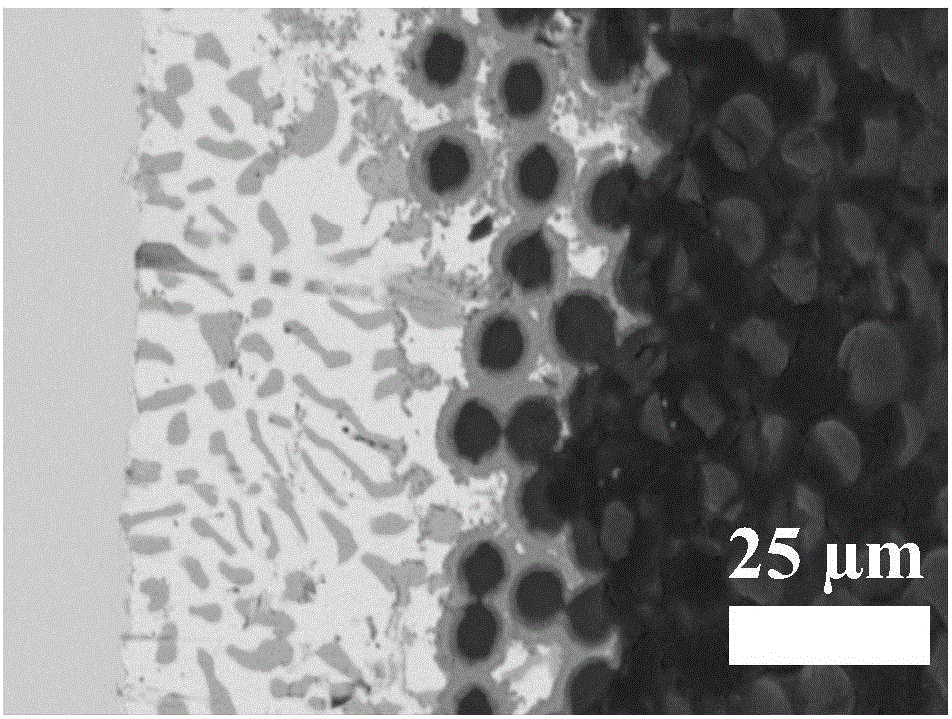

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one, a kind of SiO described in this embodiment mode 2 The method for surface activation assisted brazing of ceramic matrix composite materials is specifically carried out according to the following steps:

[0027] 1. SiO 2 The ceramic matrix composite material, brazing material and metal material were polished with sandpaper and cleaned with acetone for 10-20 minutes to remove impurities to obtain SiO with a clean surface. 2 Ceramic matrix composites, brazing filler metals, and metallic materials; SiO that removes impurities from the surface 2 The ceramic matrix composite material is soaked in an aqueous glucose solution with a mass concentration of 5% to 25% for 0.5min to 10min, and then the SiO 2 The ceramic matrix composite material is placed in an oven, heated to 50°C to 120°C, and kept for 1min to 10min. This process is repeated 2 to 5 times to obtain SiO with uniform glucose small molecule particles on the surface. 2 ceramic matrix composit...

specific Embodiment approach 2

[0033] Specific embodiment two: the difference between this specific embodiment and specific embodiment one is: the SiO described in step one 2 Ceramic matrix composites are quartz fiber woven ceramic matrix composites. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the brazing material described in step 1 is foil or powder. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com