Resourceful treatment method for aluminum ash

A treatment method and resource recovery technology, applied in the field of aluminum ash resource recovery, can solve problems such as difficulty in removing sodium and alkali, long process flow, high investment costs, etc., and achieve benefits for environmental protection, broad market prospects, and improved utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

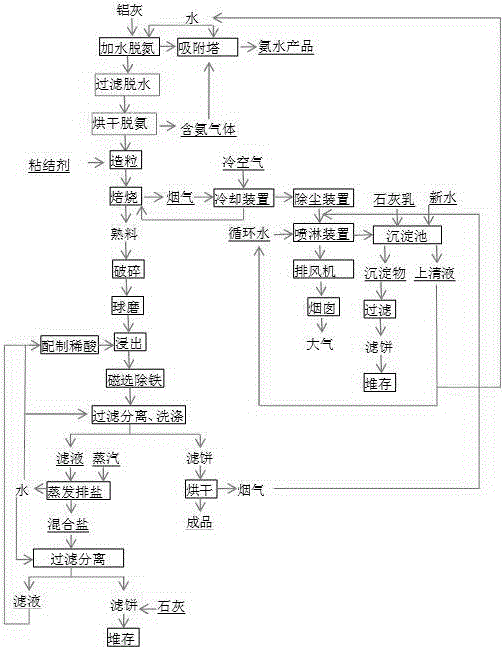

Image

Examples

Embodiment 1

[0047] A kind of aluminum ash recycling treatment method, used aluminum ash is Al 2 o 3 Aluminum ash with a content of 80% and a particle size of 60% under a 160-mesh sieve are sequentially subjected to denitrification, fluorine, arsenic treatment, metal impurity removal treatment, and finished product drying, such as figure 1 as shown,

[0048] a. the denitrification, fluorine, arsenic treatment comprises the following steps:

[0049] (a1) Hydrolytic denitrification: add water to aluminum ash and mix to form a slurry, the liquid-solid ratio is 3:1, the temperature is 40°C, and the stirring time is 0.5 hours. The aluminum nitride in the aluminum ash contacts with the water phase to form ammonia Gas, the reaction formula is as follows:

[0050] AlN+3H 2 O → Al(OH) 3 +NH 3 ↑

[0051] The generated ammonia gas escapes and enters the ammonia gas absorption tower, and the ammonia gas that enters is sprayed with circulating water in the ammonia gas absorption tower;

[00...

Embodiment 2

[0065] A kind of aluminum ash recycling treatment method, used aluminum ash is Al 2 o 3 Aluminum ash with a content of 85% and a particle size of 60% under a 160-mesh sieve are sequentially subjected to denitrification, fluorine, arsenic treatment, metal impurity removal treatment, and finished product drying, such as figure 1 as shown,

[0066] a. the denitrification, fluorine, arsenic treatment comprises the following steps:

[0067] (a1) Hydrolytic denitrification: add water to aluminum ash and mix to form a slurry, the liquid-solid ratio is 4:1, the temperature is 50°C, and the stirring time is 0.8 hours. The aluminum nitride in the aluminum ash contacts with the water phase to form ammonia Gas, the reaction formula is as follows:

[0068] AlN+3H 2 O → Al(OH) 3 +NH 3 ↑

[0069] The generated ammonia gas escapes and enters the ammonia gas absorption tower, and the ammonia gas that enters is sprayed with circulating water in the ammonia gas absorption tower;

[00...

Embodiment 3

[0083] A kind of aluminum ash recycling treatment method, used aluminum ash is Al 2 o 3 Aluminum ash with a content of 88% and a particle size of 60% under a 160-mesh sieve are sequentially subjected to denitrification, fluorine, arsenic treatment, metal impurity removal treatment, and finished product drying, such as figure 1 as shown,

[0084] a. the denitrification, fluorine, arsenic treatment comprises the following steps:

[0085](a1) Hydrolytic denitrification: add water to aluminum ash and mix to form a slurry, the liquid-solid ratio is 5:1, the temperature is 60°C, and the time is 1.0 hour while stirring continuously, the aluminum nitride in the aluminum ash contacts with the water phase to form ammonia Gas, the reaction formula is as follows:

[0086] AlN+3H 2 O → Al(OH) 3 +NH 3 ↑

[0087] The generated ammonia gas escapes and enters the ammonia gas absorption tower, and the ammonia gas that enters is sprayed with circulating water in the ammonia gas absorpt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com