Stable-flow novel descaling nozzle

A kind of stable flow, new technology, applied in the direction of spraying device, spraying device, etc., can solve the problems of many nozzles, prone to fine seams at the connection, unstable connection of nozzles, etc., to avoid excessive impact force and even water pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

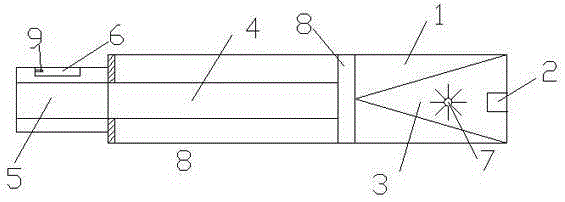

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] A new type of descaling nozzle with steady flow, comprising a nozzle head 1, a water outlet 2 is arranged on the nozzle head 1, a mixing chamber 3 is connected behind the water outlet 2, a conveying water channel 4 is arranged behind the mixing chamber 3, and a conveying water channel 4 is provided outside the water outlet 2 The pipe body, the rear part of the pipe body is provided with a connecting device 5, the connecting device 5 is provided with a fixing hole 6, and the mixing chamber 3 is provided with a water blocking piece 7, which is a spiral structure, and the water blocking piece 7 is inserted in the middle There are fixed columns, and the water-blocking sheets 7 are evenly distributed around the fixed ones in a fan-shaped structure. There is a filter device between the mixing chamber 3 and the delivery water channel 4. The filter device is a filter scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com