Salt-dye separating nanofiltration membrane as well as preparation method and application thereof

A technology of nanofiltration membrane and basement membrane, which is applied in semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of general salt permeability, concentration polarization, and small flux, and achieve the realization of salt dyeing Effects of waste water treatment, easy cleaning, and shortened operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

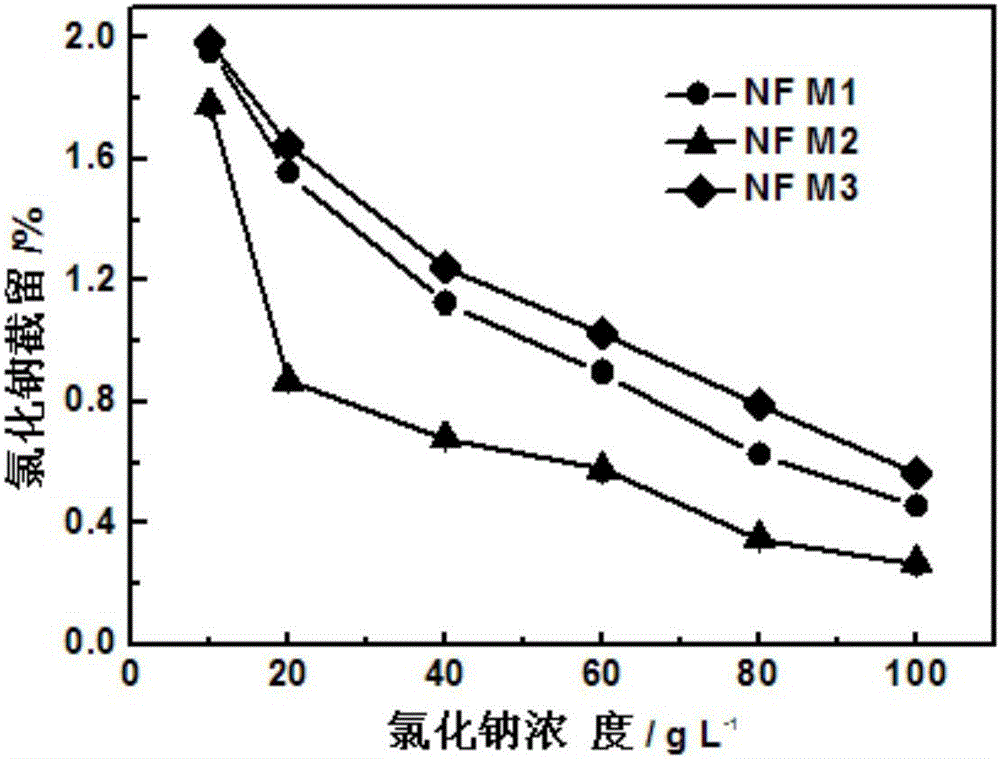

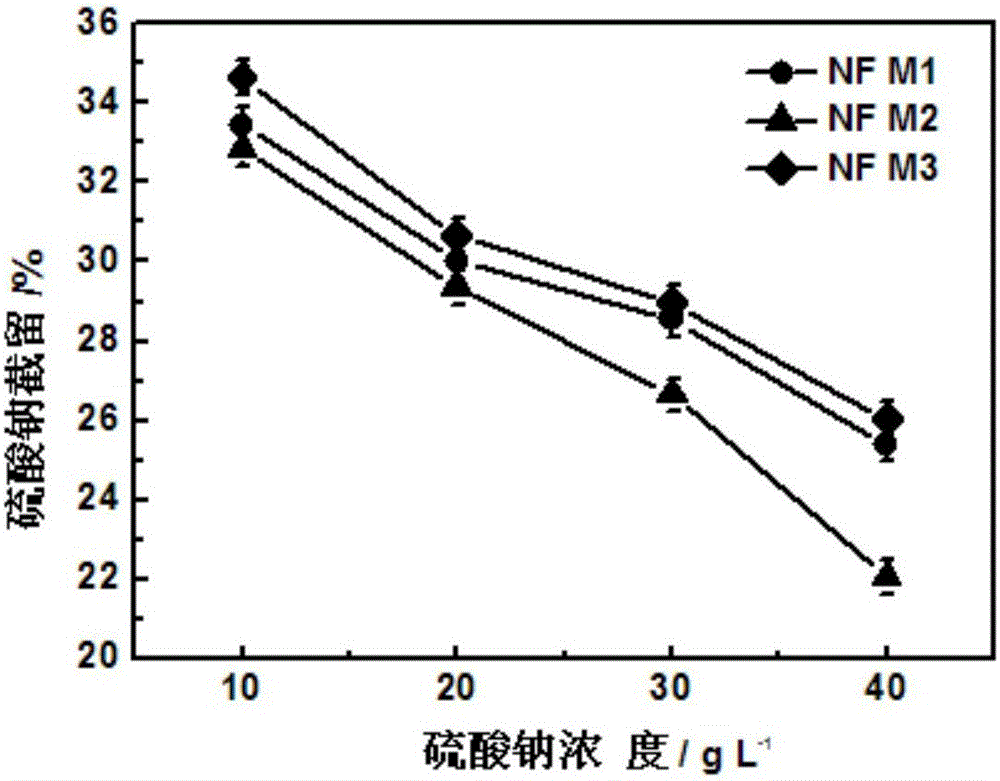

[0034] Preparation of nanofiltration membrane M1

[0035] Prepare 0.1wt% BDSA aqueous solution, and add triethylamine to adjust the pH to 10. Then pour the solution onto the surface of the polysulfone (PSF) basement membrane, pour out the solution after immersion for 5 minutes, and let it dry naturally in the air. Configure 0.2wt% TMC organic solution (n-hexane), then pour it on the surface of the above-mentioned membrane and contact with it for 20s to remove excess organic solvent. After natural air drying, the membrane was stored in deionized water.

Embodiment 2

[0037] Preparation of nanofiltration membrane M2

[0038] Prepare 0.2wt% BDSA aqueous solution, and add triethylamine to adjust the pH to 11. Then pour the solution onto the surface of the polyethersulfone (PES) base membrane, pour out the solution after immersion for 3 minutes, and let it dry naturally in the air. Configure 0.1wt% TMC organic solution (n-hexane), then pour it onto the surface of the above-mentioned membrane and contact with it for 30s to remove excess organic solvent. After natural air drying, the membrane was stored in deionized water. Nanofiltration membrane morphology as figure 1 -As shown in (a), there are protrusions on the surface of the membrane, which indicates that there is a polyamide layer formed on the surface of the basement membrane; from the cross-sectional scanning electron microscope figure 1 -(b) It can be clearly seen that there is a relatively thin polyamide selective layer on the surface of the base film.

Embodiment 3

[0040] Preparation of nanofiltration membrane M3

[0041]Prepare 0.5wt% BDSA aqueous solution, and add sodium carbonate to adjust the pH to 11. Then pour the solution onto the surface of the polysulfone (PSF) basement membrane, pour out the solution after immersion for 2 minutes, and let it dry naturally in the air. Configure 0.05wt% TMC organic solution (cyclohexane), then pour it on the surface of the above-mentioned membrane and contact with it for 60s to remove excess organic solvent. After natural air drying, the membrane was stored in deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com