Electrodialyzer and solution treating method thereof

A technology of electrodialyzer and electrode plate, which is applied in the field of solution treatment equipment, and can solve the problem of single solution treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

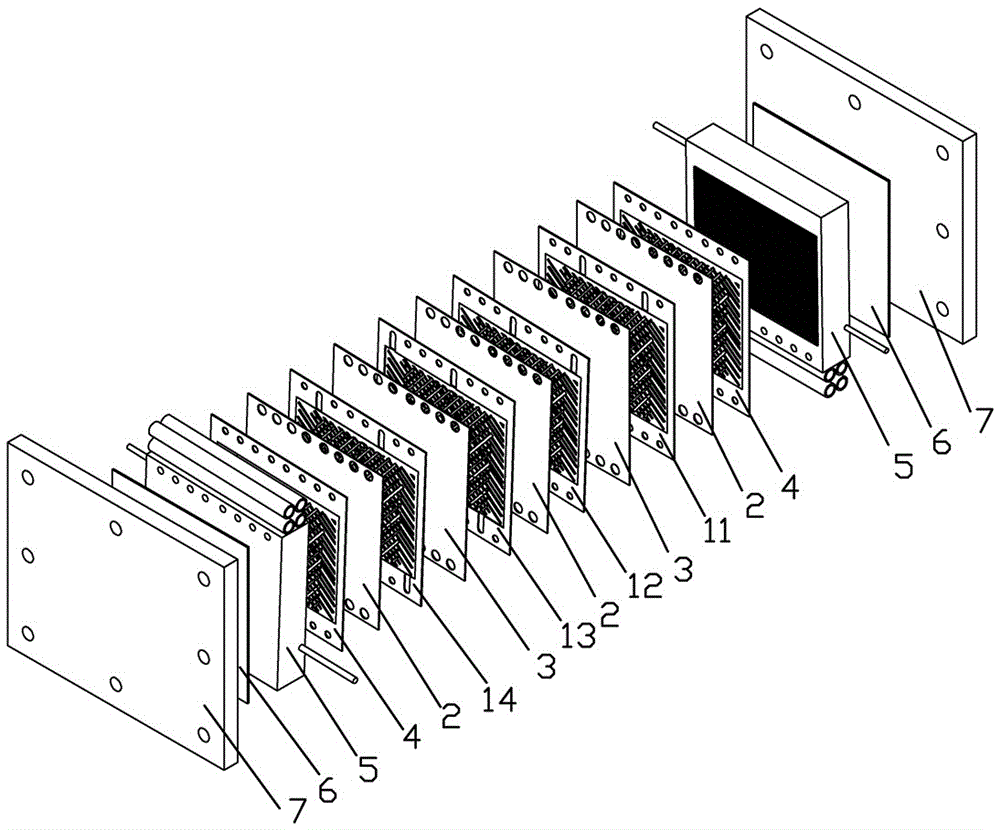

[0053] Such as figure 1 As shown, a plate-and-frame electrodialyzer includes end plates 7, rubber gaskets 6, electrode plates 5, membrane stacks from outside to inside, and is used to connect end plates 7, rubber gaskets 6, electrode plates 5 , The fasteners for fastening connection of membrane stacks.

[0054] The membrane stack partitions, cation exchange membranes 2, and anion exchange membranes 3 are arranged at intervals; wherein, the partitions located at the outermost two ends of the membrane stack are end partitions 4, located between the anion exchange membrane 3 and the cation exchange membrane 2 The clapboard is the middle clapboard.

[0055] The specific arrangement structure of the membrane stack is:

[0056] End partition 4—cation exchange membrane 2—first intermediate partition 11—anion exchange membrane 3—second intermediate partition 12—cation exchange membrane 2—third intermediate partition 13—anion exchange membrane 3— The fourth type of intermediate part...

Embodiment 2

[0093] X is set as the liquid water to be treated, and Y is set as the liquid water to be treated;

[0094] AB is the ion of liquid potassium chloride aqueous solution to be treated, and wherein, A is potassium ion, and B is chloride ion;

[0095] CD is the ion of the liquid humic acid aqueous solution to be treated, wherein, C is a hydrogen ion, and D is a humate ion.

[0096] The specific steps of solution processing are:

[0097] Through 4 different water inlet pipes, X flows into the second type ion migration compartment 23, Y flows into the second type ion migration compartment 21, potassium chloride aqueous solution (AB) flows into the first type ion migration compartment 22 , the aqueous solution of humic acid (CD) flows into the second type ion migration compartment 24 .

[0098] Potassium chloride is used as the polar water in the electrode chamber on the positive side, and potassium chloride is used as the polar water in the electrode chamber on the negative electr...

Embodiment 3

[0104] X is set as the liquid sodium chloride water to be processed, and Y is set as the liquid sodium chloride water to be processed;

[0105] AB is the ion of liquid potassium sulfate aqueous solution to be treated, and wherein, A is potassium ion, and B is sulfate ion;

[0106] CD is the ions of the mixed aqueous solution of magnesium nitrate and calcium chloride to be treated, wherein C is magnesium ions and calcium ions, and D is nitrate ions and chloride ions.

[0107] The specific steps of solution processing are:

[0108] Through 4 different water inlet pipes, X flows into the second type ion migration compartment 23, Y flows into the second type ion migration compartment 21, potassium sulfate aqueous solution (AB) flows into the first type ion migration compartment 22, The mixed aqueous solution of magnesium nitrate and calcium chloride (CD) flows into the second type of ion migration compartment 24 .

[0109] Potassium sulfate is used as the polar water in the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com