Mechanical-sugarcane- peeling cleaning machine with recycling mechanism

A recycling mechanism and mechanical technology, applied in the fields of vegetable or fruit peeling, food processing, food science, etc., can solve the problems of impracticality, broken mouth, etc., and achieve convenient collection, simple structure and high peeling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

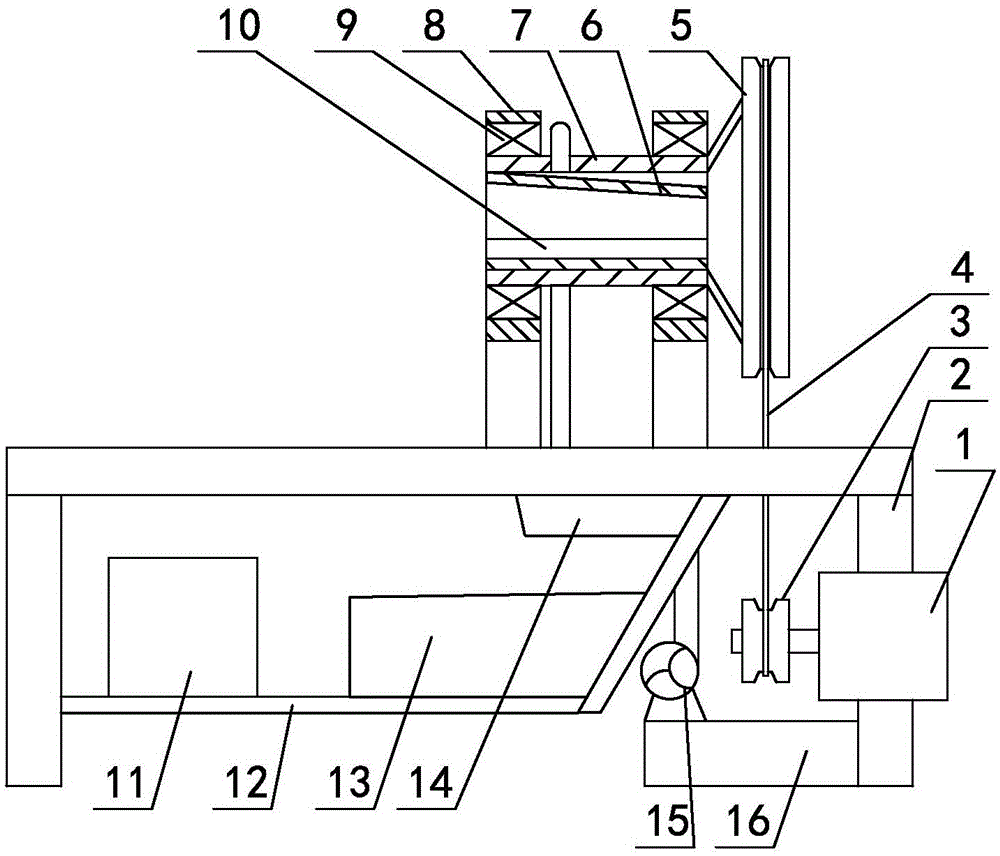

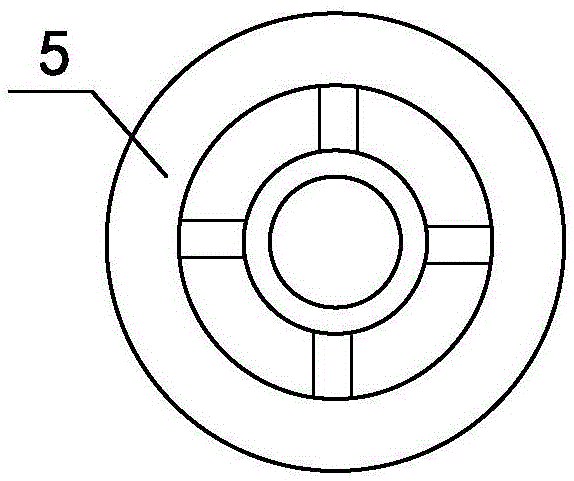

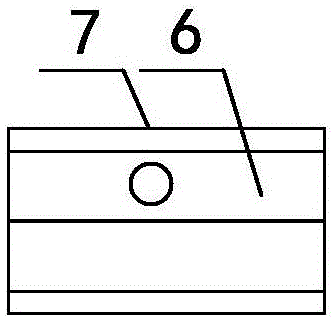

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the mechanical sugarcane peeling and cleaning machine with a recovery mechanism includes a workbench 2 and an adjustment plate 10. Two left and right parallel bearing seats 8 are arranged on the workbench 2, and the corresponding two bearing seats 8 are horizontally arranged. There is a scraper cover 7, and the left and right ends of the scraper cover 7 communicate with the outside world. On the inner top wall of the scraper cover 7, a blade 6 with a high left and a low right is arranged horizontally. The blade of the blade 6 is tangent to the rotation direction of the scraper cover 7 , the corresponding blade 6 is provided with a discharge port on the scraper cover 7, and the two ends of the scraper cover 7 are respectively installed on the corresponding bearing housing 8 through bearings 9, and the right end of the scraper cover 7 is fixed with a handle for the rotation of the scraper cover 7. Large belt...

Embodiment 2

[0027] On the basis of the first embodiment, the inclination angle of the blade 6 is changed to 15 degrees; the inner diameter of the scraper sheath 7 is changed to 60 mm.

[0028] Others are the same as embodiment one.

Embodiment 3

[0030] On the basis of the first embodiment, the inclination angle of the blade 6 is changed to 10 degrees; the inner diameter of the scraper sheath 7 is changed to 40 mm.

[0031] Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com