Formation method for high-voltage lithium ion flexibly packaged battery

A chemical formation method and soft-pack battery technology, which is applied in the field of lithium-ion batteries, can solve problems such as easy gas generation and battery flatulence, and achieve the effects of reducing impact, ensuring liquid retention and hardness, and improving electrical performance and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

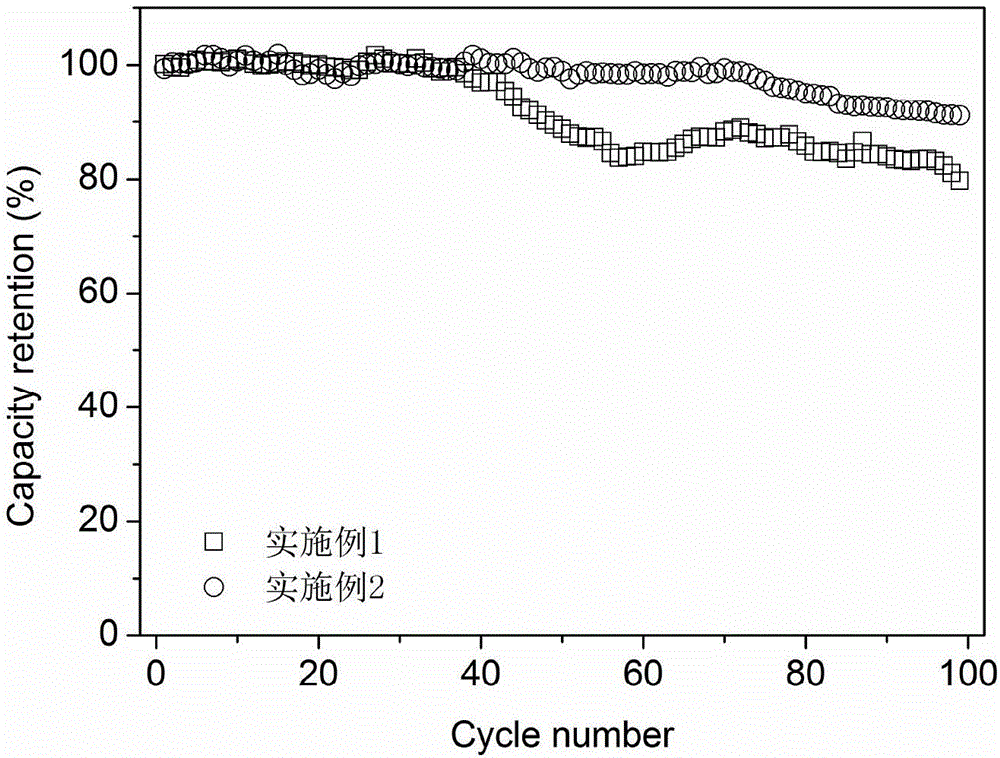

Embodiment 1

[0029] The formation method of the high-voltage lithium-ion soft pack battery of this embodiment comprises the following steps:

[0030] S1. Put the soft-packed cells that have been injected into the vacuum for 12 hours, and then vacuum seal. This process ensures the full infiltration of the electrolyte and is conducive to the completion of the formation process. Put the sealed cells into the adjustable In the pressure fixture, set the fixture pressure to 0.1MPa, and the temperature is 45°C, charge with the first current of 0.02C to the first cut-off voltage of 3.8v, and leave it for 10min;

[0031] S2. On the basis of step S1, adjust the clamp pressure to 0.05MPa, and at a temperature of 45°C, charge the battery with a second current of 0.05C to a second cut-off voltage of 4.4v, and leave it for 10 minutes;

[0032] S3. On the basis of step S2, adjust the clamp pressure to 0.02MPa, and at a temperature of 55°C, charge with the third current of 0.1C to a full-state voltage of ...

Embodiment 2

[0038] The formation method of the high-voltage lithium-ion soft pack battery of this embodiment comprises the following steps:

[0039] S1. Put the soft-packed cells that have been injected into the vacuum for 12 hours, and then vacuum seal. This process ensures the full infiltration of the electrolyte and is conducive to the completion of the formation process. Put the sealed cells into the adjustable In the pressure fixture, set the fixture pressure to 0.05MPa, and the temperature is 45°C, charge with the first current of 0.02C to the first cut-off voltage of 3.8v, and leave it for 10min;

[0040] S2. On the basis of step S1, adjust the clamp pressure to 0.05MPa, and at a temperature of 45°C, charge with the second current of 0.05C to the second cut-off voltage of 4.2v, and leave for 10min;

[0041] S3. On the basis of step S2, adjust the clamp pressure to 0.02MPa, and at a temperature of 55°C, charge with the third current of 0.1C to a full-state voltage of 4.7v, and leave...

Embodiment 3

[0047] The formation method of the high-voltage lithium-ion soft pack battery of this embodiment comprises the following steps:

[0048] S1. Put the soft-packed battery cells that have been injected into the open vacuum for 8 hours, and then vacuumize the seal. This process ensures the full infiltration of the electrolyte and is conducive to the completion of the formation process. Put the sealed battery cells into the adjustable In the pressure fixture, set the fixture pressure to 0.05MPa and the temperature to 40°C, charge with the first current of 0.01C to the first cut-off voltage of 3.5v, and leave it for 8min;

[0049] S2. On the basis of step S1, adjust the clamp pressure to 0.03MPa, and at a temperature of 40°C, charge with a second current of 0.03C to a second cut-off voltage of 4.2v, and leave for 8 minutes;

[0050] S3. On the basis of step S2, adjust the clamp pressure to 0.01MPa, and at a temperature of 50°C, charge with the third current of 0.05C to a full-state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com