Battery current collector and preparation method as well as alkaline zinc-manganese battery

A zinc-manganese battery and battery collection technology, which is applied to battery electrodes, electrode carriers/current collectors, dry batteries, etc., can solve the problems of liquid leakage, uncontrolled over-discharge depth, and large battery gas evolution, and achieves reduction of production costs. Solving the effect of overdischarge leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

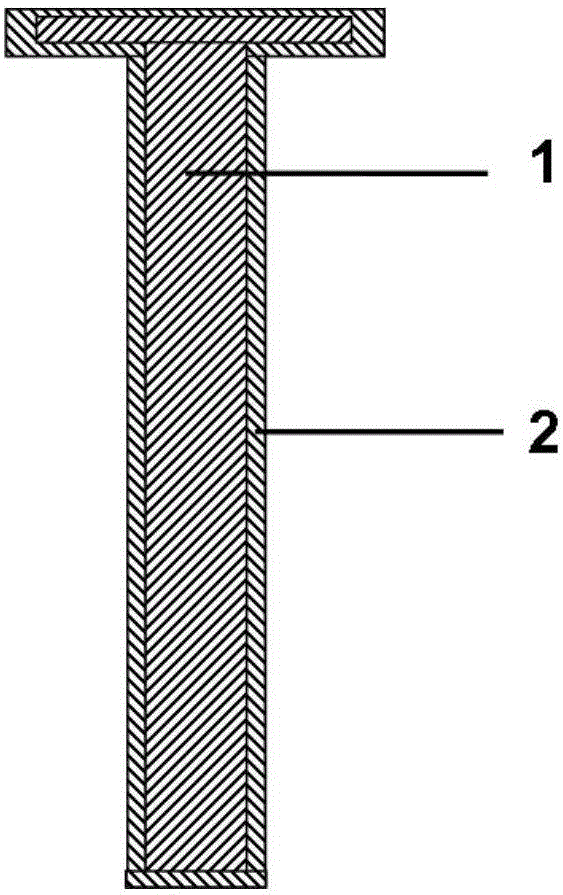

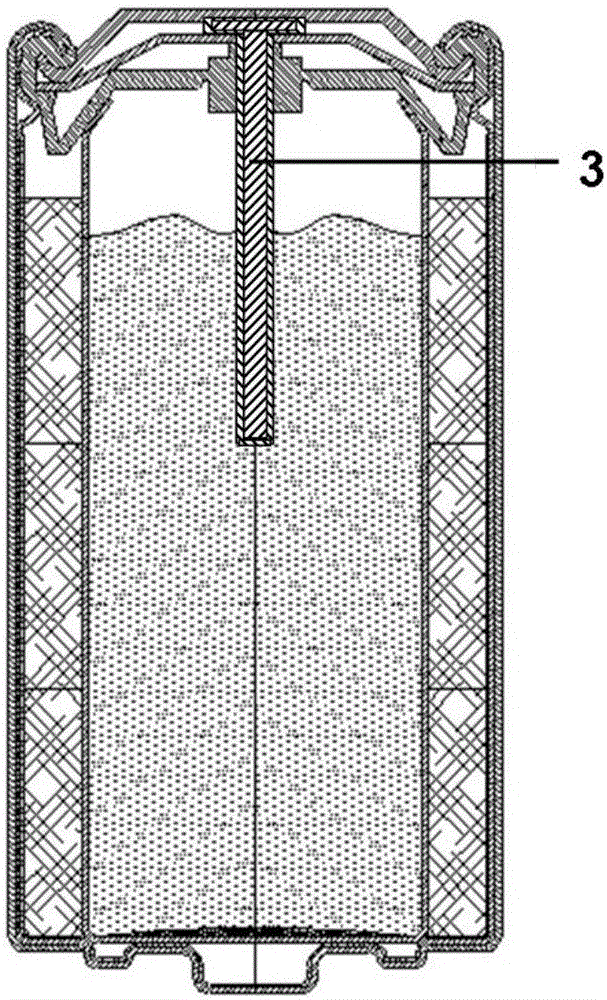

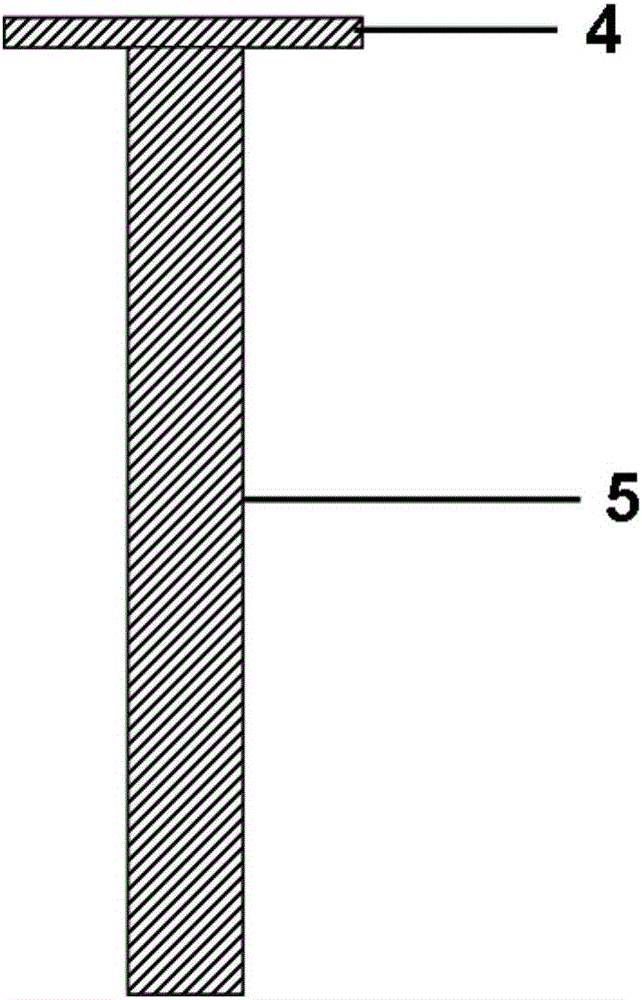

Embodiment 1

[0055] Take the insulating body made of styrene-butadiene rubber, and use electroless plating to plate a tin plating (coating) layer with a thickness of 20 μm on its entire surface, and then use secondary electroless plating to coat the surface of the wide end of the insulating body with a thickness of 30 μm. The tin layer of the new structure is obtained to control the over-discharge depth of the current collector; through the FDK production line, the positive electrode ring of the steel shell is inserted, the separator paper is inserted, the zinc paste is injected, and the negative electrode bottom of the new structure current collector is inserted and welded with the sealing ring Composed of electron collection, crimping, shaping and sealing to obtain LR6 alkaline zinc-manganese batteries that can self-control the depth of over-discharge;

[0056] The obtained LR6 battery was continuously over-discharged with four 80Ω resistors connected in series for 72 hours. After the cir...

Embodiment 2

[0059] Take the insulating main body made of polypropylene, and use electroless plating followed by electroplating to plate a zinc plating (coating) layer with a thickness of 50 μm on the entire surface, and then use secondary electroless plating to coat the surface of the wide end of the insulating main body with a thickness of 50 μm. 20μm tin layer to obtain a new structure of current collectors with controlled over-discharge depth; through the FDK production line, through the insertion of the positive electrode ring of the steel shell, the insertion of diaphragm paper, the injection of zinc paste, and the insertion of the negative electrode bottom of the new structure of the current collector after welding and sealing Collecting electrons composed of rings, crimping and shaping to obtain LR6 alkaline zinc-manganese batteries that can self-control the depth of over-discharge;

[0060] The obtained LR6 battery was continuously over-discharged with four 80Ω resistors connected ...

Embodiment 3

[0063] Take the insulating body made of polymethyl methacrylate, and use chemical plating to plate an indium plating (coating) layer with a thickness of 10 μm on its surface, and then use secondary chemical plating to plate the surface of the wide end of the insulating body with a thickness of 10 μm. The indium layer of 40 μm is used to obtain a current collector with a new structure that controls the over-discharge depth; through the FDK production line, the positive electrode ring of the steel shell is inserted, the diaphragm paper is inserted, zinc paste is injected, and the negative electrode bottom of the current collector with the new structure is inserted and welded with Collecting electrons composed of sealing rings, crimping and shaping to obtain LR6 alkaline zinc-manganese batteries that can self-control over-discharge depth;

[0064] The obtained LR6 battery was continuously over-discharged with four 80Ω resistors connected in series for 72 hours. After the circuit w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com