Paver with preheating function and operation method thereof

A paver and preheating technology, which is applied to roads, road repairs, roads, etc., can solve the problems of poor bonding quality between high-temperature asphalt mixture and normal-temperature road surface, and improve work efficiency, pre-compaction degree, and efficiency The effect of improving and extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

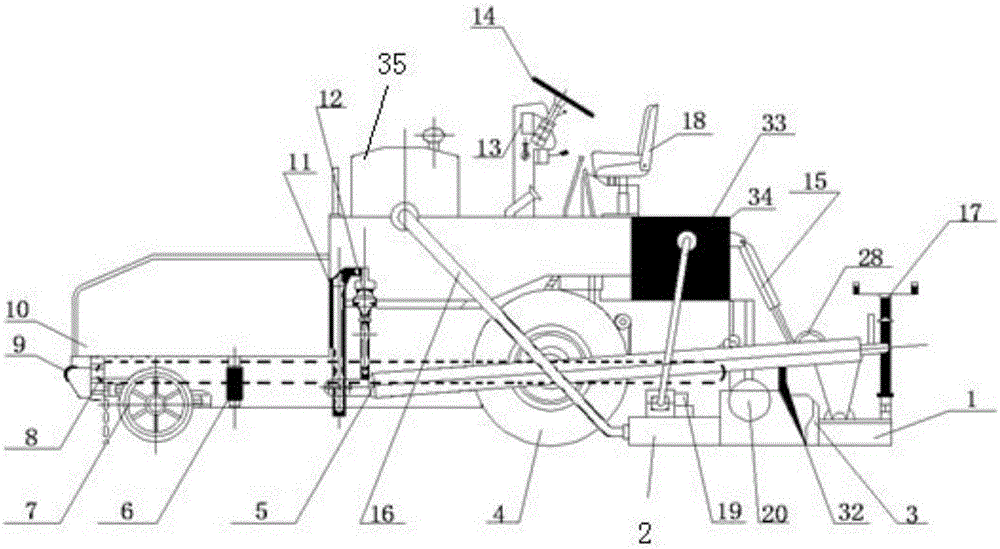

[0032] The present invention is further described below in conjunction with accompanying drawing:

[0033] see Figure 1 to Figure 4As shown, a paver with preheating function includes a body, a heater 2, a screed 1, a natural gas storage device 33, a screed leveling system, a material transport system and a diesel engine 35; the screed leveling system, transport Both the material system and the diesel engine 35 are set on the machine body, the screed 1 is connected with the screed leveling system; A hot exhaust pipe 16 is arranged between them; a natural gas storage device 33 is installed on one side of the diesel engine 35, and a material delivery system is installed on the other side; a gas pipe 34 is arranged between the natural gas storage device 33 and the heater 2;

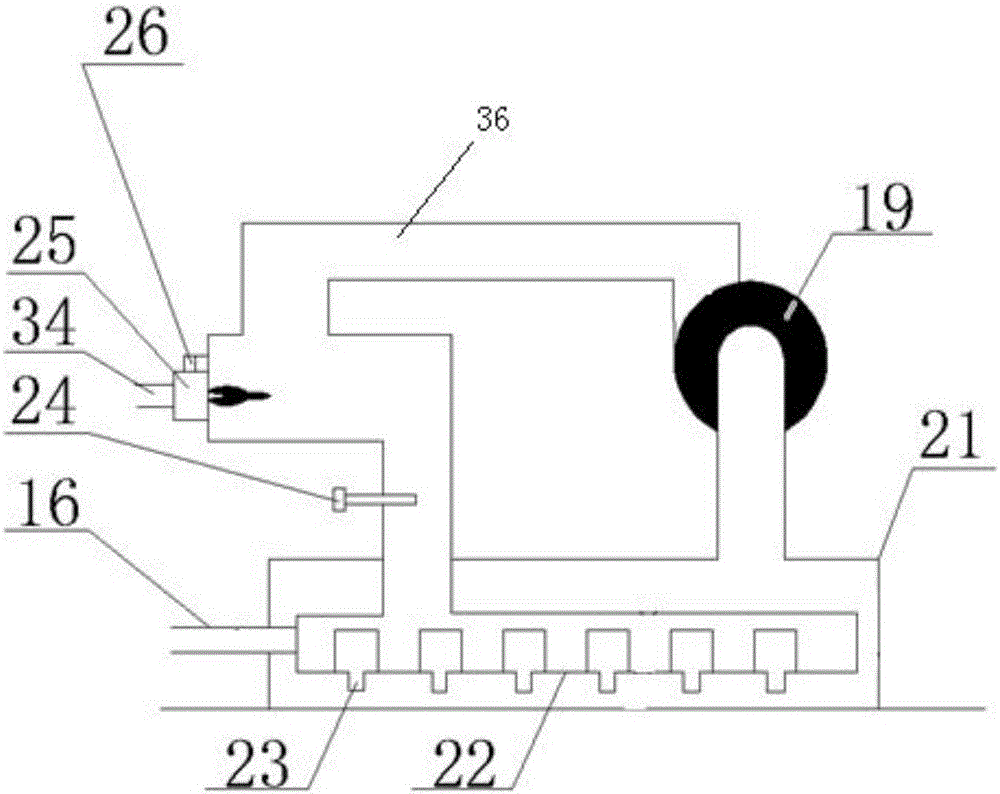

[0034] Described heater 2 comprises heater main body, circulation blower 19, burner 25, circulation pipe 36 and casing 21; The heater main body is a hollow rectangular parallelepiped structure, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com