A kind of graphene-nickel composite fiber and preparation method thereof

A graphene fiber and composite fiber technology, applied in fiber treatment, wet spinning, physical treatment, etc., can solve problems such as weak adhesion, and achieve the effect of less time and energy consumption, dense fiber structure and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

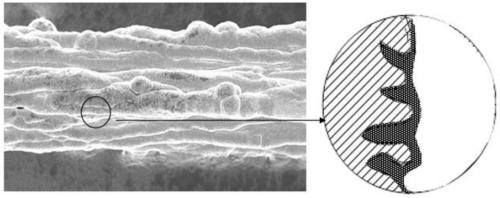

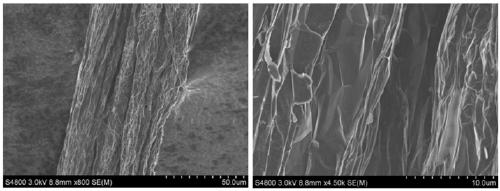

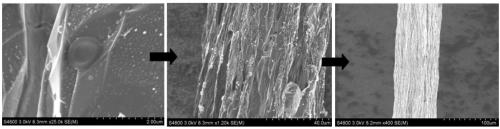

Image

Examples

Embodiment 1

[0025] A kind of electroplating method prepares the method for graphene and nickel composite fiber, comprises following process:

[0026] (1) Utilize the wet spinning method to prepare graphene oxide fibers with a diameter of 3 microns, specifically: the spinning solution of wet spinning is: graphene oxide with a sheet diameter of 5 microns (Carbon Valley Shangxi) In the dispersion liquid in dimethylformamide, the concentration of graphene oxide is 4mg / mL; The inner diameter of spinning head is 60 microns; Coagulation bath is the mixed solution of ethyl acetate and dichloromethane (both volume ratios are 1 : 1), the external heating temperature when receiving the wire is 200 ℃.

[0027] (2) Place the graphene oxide fiber in a high-temperature furnace for heating and reduction at a temperature of 1000° C. After heating for 1.5 hours, a graphene fiber with a diameter of 3 microns is obtained.

[0028] (3) Graphene fibers are fixed on the negative pole of the electroplating tank...

Embodiment 2

[0030] A kind of electroplating method prepares the method for graphene and nickel composite fiber, comprises following process,

[0031] (1) Utilize the wet spinning method to prepare graphene oxide fibers with a diameter of 10 microns, specifically: the spinning solution of wet spinning is: graphene oxide with a sheet diameter of 5 microns (Carbon Gu Shangxi) In the dispersion liquid in dimethylformamide, the concentration of graphene oxide is 8mg / mL; The internal diameter of spinning head is 250 microns; Coagulation bath is the mixed solution of ethyl acetate and dichloromethane (both volume ratios are 10 : 1), the external heating temperature when receiving wire is 80 ℃.

[0032] (2) Place the graphene oxide fiber in a high-temperature furnace to heat and reduce it at a temperature of 2200° C. After heating for 3 hours, a graphene fiber with a diameter of 10 microns is obtained;

[0033] (3) Graphene fiber is fixed on the negative pole of electroplating tank and carries o...

Embodiment 3

[0035] A kind of electroplating method prepares the method for graphene and nickel composite fiber, comprises following process:

[0036] (1) Utilize the wet spinning method to prepare graphene oxide fibers with a diameter of 30 microns, specifically: the spinning solution of wet spinning is: graphene oxide with a sheet diameter of 50 microns (Carbon Valley Shangxi) In the dispersion liquid in dimethylformamide, the concentration of graphene oxide is 11mg / mL; The inner diameter of spinning head is 500 microns; The coagulation bath is the mixed solution of ethyl acetate and dichloromethane (both volume ratios are 200 : 1), the external heating temperature when receiving the wire is 100 ℃.

[0037] (2) Put the graphene oxide fiber in a high-temperature furnace for heating and reduction at a temperature of 2700° C. After heating for 1 hour, a graphene fiber with a diameter of 30 microns is obtained.

[0038] (3) Graphene fiber is fixed on the negative pole of electroplating tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com