Energy-efficient indirect thermal desorption carbonization device and treatment method thereof

A high-efficiency, energy-saving, carbonization device technology, used in chemical instruments and methods, combined devices, separation devices, etc., can solve the problems of deformation of the analytical chamber tube wall, corrosion resistance, non-condensable gas, and incomplete combustion, etc. The effect of cost, expansion of production capacity, and improvement of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

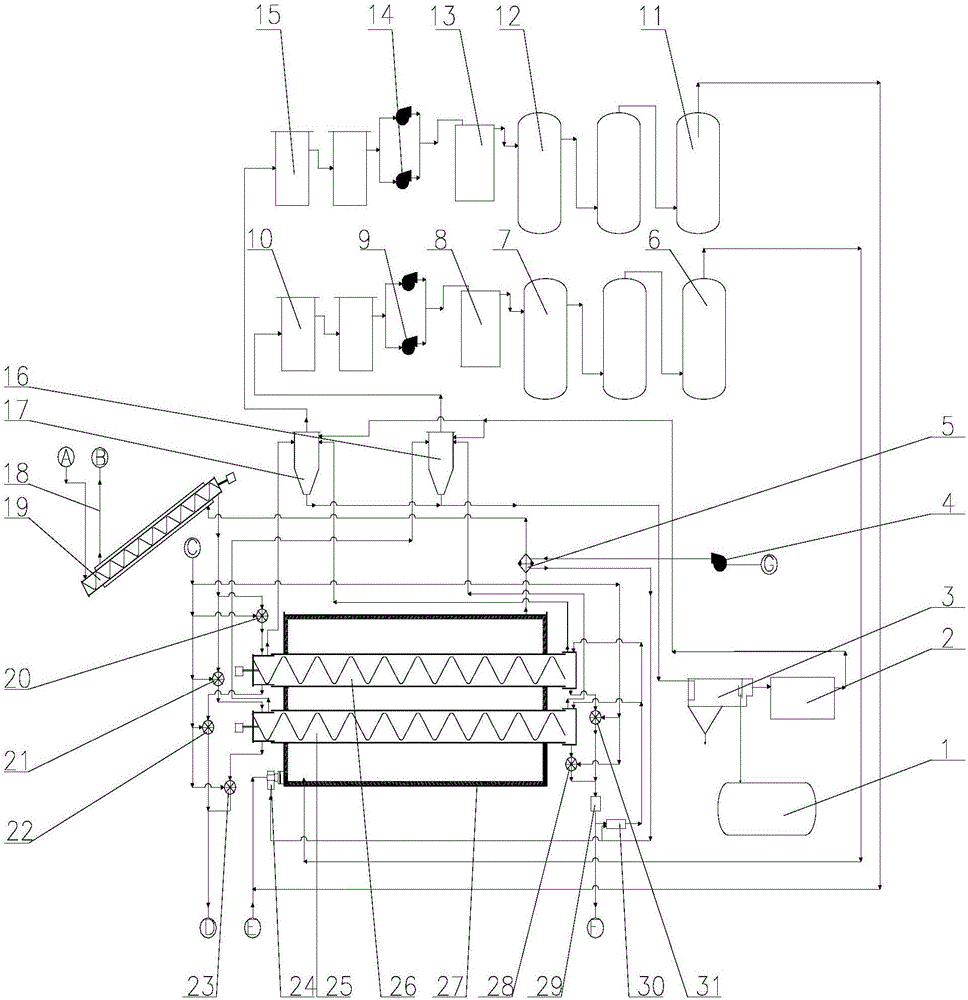

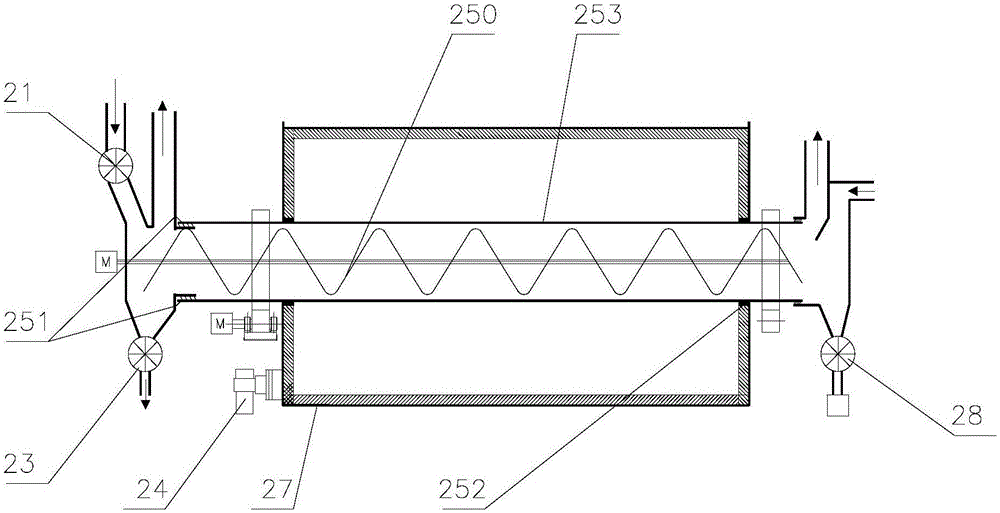

[0036] Such as Figure 1 to Figure 2 As shown, the present invention provides a high-efficiency and energy-saving indirect thermal desorption carbonization device, including a preheating feed system, a material heating system, a first non-condensable gas treatment system, a second non-condensable gas treatment system and a condensation system.

[0037] The preheating feed system includes a screw feed device 19 with a heat exchange jacket and a chimney pipe 18. The feed end of the screw feed device 19 is connected to the feed port, and the material is physically broken into a particle size smaller than 40mm granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com