Preparation method of low-cost nano-porous silica powder

A nanoporous, low-cost technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor controllability of pore structure, high heating temperature, small pores, etc., and achieve short reaction time and material structure. Control, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

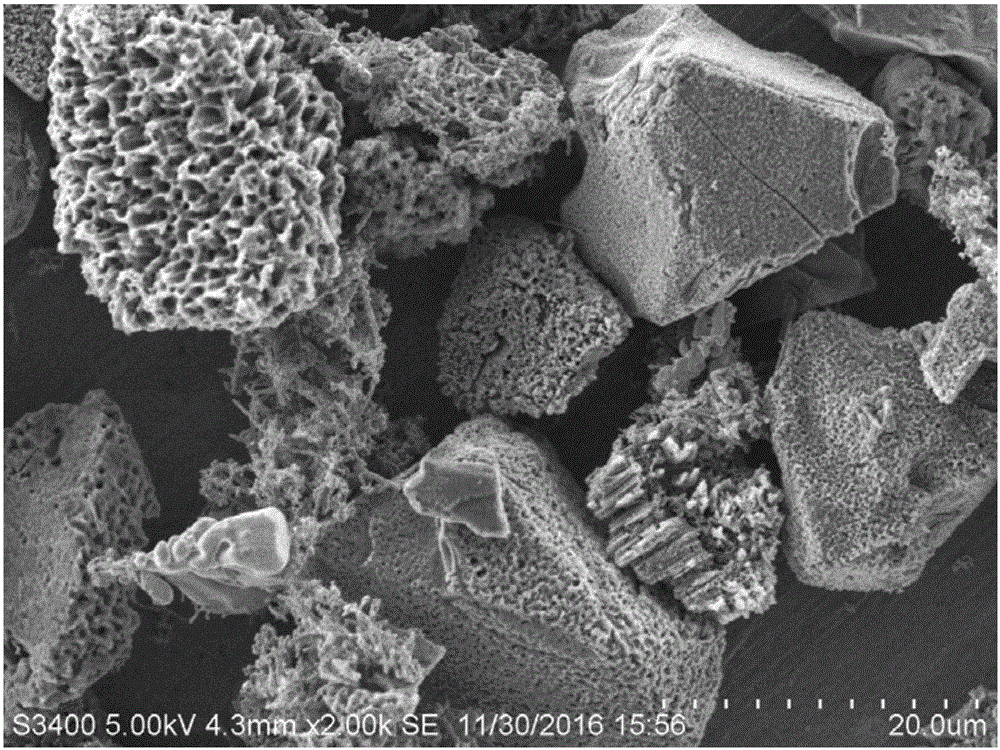

Image

Examples

Embodiment 1

[0030] The preparation method of porous silicon described in this embodiment specifically includes the following steps:

[0031] (1) Pretreatment of silicon powder: Soak and clean silicon powder (metallurgical grade silicon, particle size less than or equal to 500 μm) with 5wt% hydrofluoric acid (that is, 5% HF aqueous solution) for 10 minutes, and filter with deionized water Wash 3 times and dry;

[0032] (2) Etching of silicon powder: place silicon powder in HF, Cu(NO 3 ) 2 , ethanol and water, the concentration of HF in the mixed solution is 5mol / L, Cu(NO 3 ) 2 The concentration of the mixture is 0.06mol / L, the mass percentage of ethanol is 1%, react at room temperature 25°C for 20min, and magnetically stir at the same time (stirring speed is 300r / min), to obtain porous silicon particles;

[0033] (3) processing of silicon powder: the porous silicon particles obtained in (2) step are placed in 10% nitric acid aqueous solution and soaked for 1 hour (the mass percentage o...

Embodiment 2

[0036] The preparation method of porous silicon described in this embodiment specifically includes the following steps:

[0037] (1) Pretreatment of silicon powder: soak and clean silicon powder (metallurgical grade silicon) with 5wt% HF for 10 minutes, wash with deionized water for 3 times after filtering, and dry;

[0038] (2) Etching of silicon powder: place silicon powder in HF, Cu(NO 3 ) 2 , ethanol and water, the concentration of HF in the mixed solution is 5mol / L, Cu(NO 3 ) 2 The concentration is 0.12mol / L, ethanol is 10%, react at room temperature 25°C for 20min, and magnetic stirring is carried out at the same time (stirring speed is 300r / min), to obtain porous silicon particles;

[0039] (3) Treatment of silicon powder: soak the porous silicon particles obtained in step (2) in 10% nitric acid solution for 1 hour, and at the same time perform ultrasonic cleaning on the porous silicon to remove impurities to obtain porous silicon.

[0040](4) Cleaning of porous sil...

Embodiment 3

[0042] The preparation method of porous silicon described in this embodiment specifically includes the following steps:

[0043] (1) Pretreatment of silicon powder: soak and clean silicon powder (metallurgical grade silicon) with 5wt% HF for 10 minutes, wash with deionized water for 3 times after filtering, and dry;

[0044] (2) Etching of silicon powder: place silicon powder in HF, Fe(NO 3 ) 3 , ethanol and water, the concentration of HF in the mixed solution is 5mol / L, Fe(NO 3 ) 3 The concentration is 0.24mol / L, ethanol is 15%, react at normal temperature 25 ℃ for 30min, carry out magnetic stirring simultaneously (stirring speed is 300r / min), obtain porous silicon particle;

[0045] (3) Treatment of silicon powder: soak the porous silicon particles obtained in step (2) in 10% nitric acid aqueous solution for 1 hour, and ultrasonically clean the porous silicon to remove impurities to obtain porous silicon.

[0046] (4) Cleaning of porous silicon: the porous silicon obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com