Filter stick production logistics system based on filter stick box set material rack

A logistics system and filter rod technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of high manual labor intensity, poor working environment, low production management efficiency, etc., to meet the needs of automated production and manual labor intensity Small size, high production management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

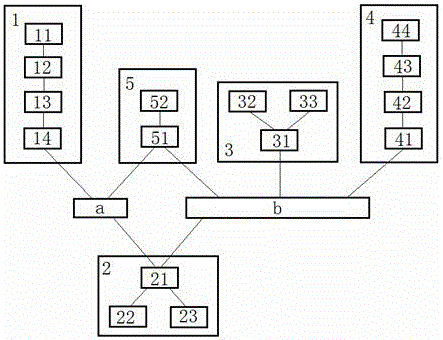

[0027] as attached figure 1 As shown, the filter rod production logistics system based on the filter rod box assembly rack includes box folding area 1, filter rod production area 2, whole pallet palletizing and packaging area 3, box packaging palletizing area 4, and filter rod box storage area 5 and the logistics central control module; the filter rod production area 2 is respectively connected with the whole pallet palletizing packaging area 3, the box-type packaging stacking area 4, and the filter rod box storage area 5, and the logistics central control module is respectively connected with the folding box area 1 , filter rod production area 2, whole pallet palletizing and packaging area 3, box packaging palletizing area 4, and filter rod box storage area 5 are connected to realize control.

[0028] The folding box area 1 includes a temporary storage area 11 for the filter rod box leather tray, a folding box operation area 12, a temporary storage area 13 for the empty filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com