Central spindle for baby carriage

A baby carriage and mandrel technology, which is applied in the directions of baby carriage/stroller, baby carriage/cradle accessories, shaft, etc. The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

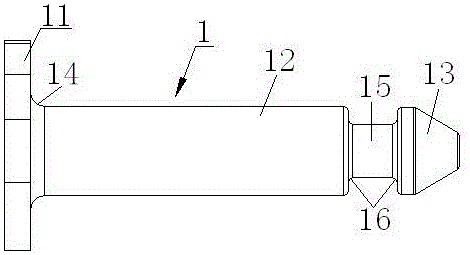

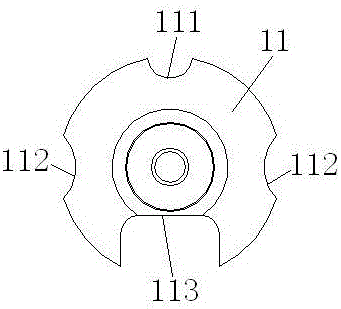

[0015] refer to Figure 1~2 , a mandrel used for a stroller, comprising a mandrel body 1, the mandrel body 1 is processed by a heat treatment process before machining to obtain comprehensive properties of strength, hardness, plasticity, and toughness. First, the mandrel body 1 Carry out graded quenching, quenching in a low-temperature salt bath or alkali bath furnace, and at the same time control the temperature of the salt bath or alkali bath near the Ms point, the mandrel body 1 stays at this temperature for 2 minutes to 5 minutes, and then take it out for air cooling, the purpose of graded cooling It is to make the temperature inside and outside the mandrel body 1 relatively uniform, and at the same time carry out martensitic transformation, which can greatly reduce the quenching stress and prevent the mandrel body 1 from deforming and cracking. The hardness after fire is 200-330HB, so that the strength, hardness, plasticity and toughness of the mandrel body 1 have better m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com