Method for manufacturing three-dimensional object part by part and layer by layer

A three-dimensional object, layer-by-layer manufacturing technology, applied in the directions of additive manufacturing, process efficiency improvement, energy efficiency improvement, etc., can solve the problems of scrapping three-dimensional objects, and the shape accuracy and dimensional accuracy of three-dimensional objects cannot meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

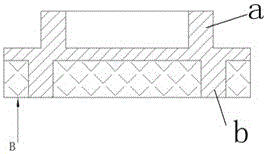

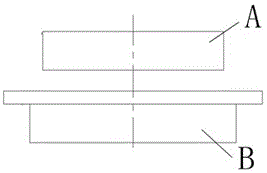

[0020] In the process of manufacturing metal three-dimensional objects layer by layer using powdered materials, the manufacturing of overhanging surfaces often occurs, that is, layered slices form suspended parts that are not self-supporting. Generally, when the slice thickness is fixed, the greater the length of the suspended part, the smaller the angle formed by the slice and the horizontal plane, which brings more inconvenience to the manufacture of three-dimensional objects. During the manufacturing process, it is necessary to design support to fix the suspended surface so that It does not warp and deform. However, the manufacturing process of the support structure includes the removal process, which will affect the manufacturing accuracy of the three-dimensional object, especially when the support structure is designed on the characteristic surface, it is often difficult to meet the requirements of manufacturing accuracy.

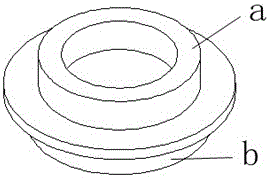

[0021] figure 1 with figure 2 Shown is a three-dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com