Fire-proof and high-temperature-resistant vacuum insulation glove

A technology of vacuum insulation and high temperature resistance, applied in the field of solar power generation, can solve the problems of limited high temperature resistance or heat resistant radiation, and single material of high temperature resistant gloves, so as to avoid instability, inhibit heat conduction and heat convection, and reduce the possibility of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

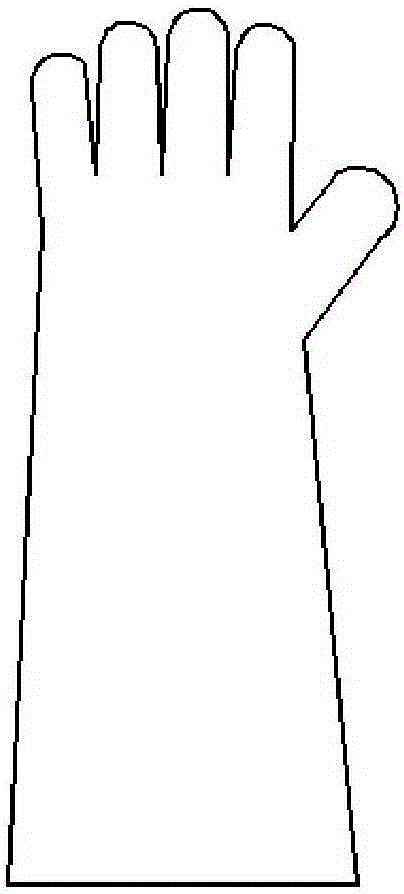

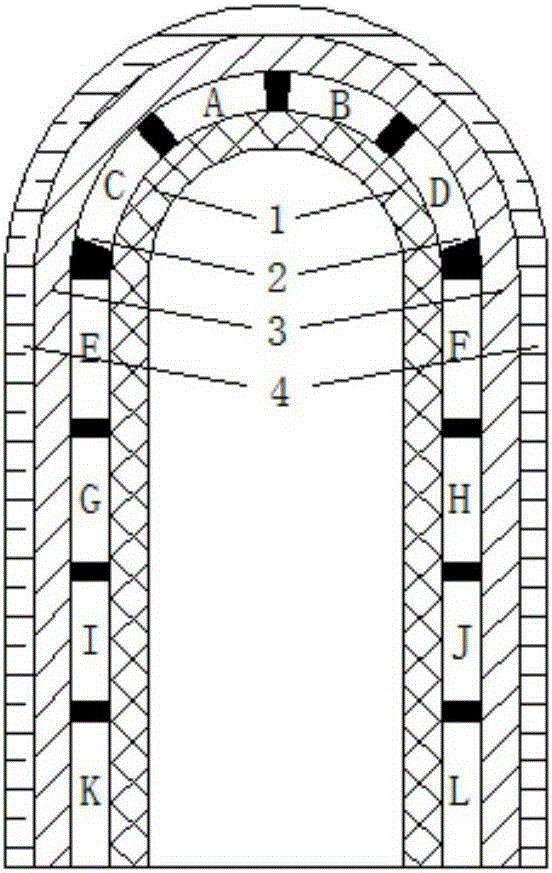

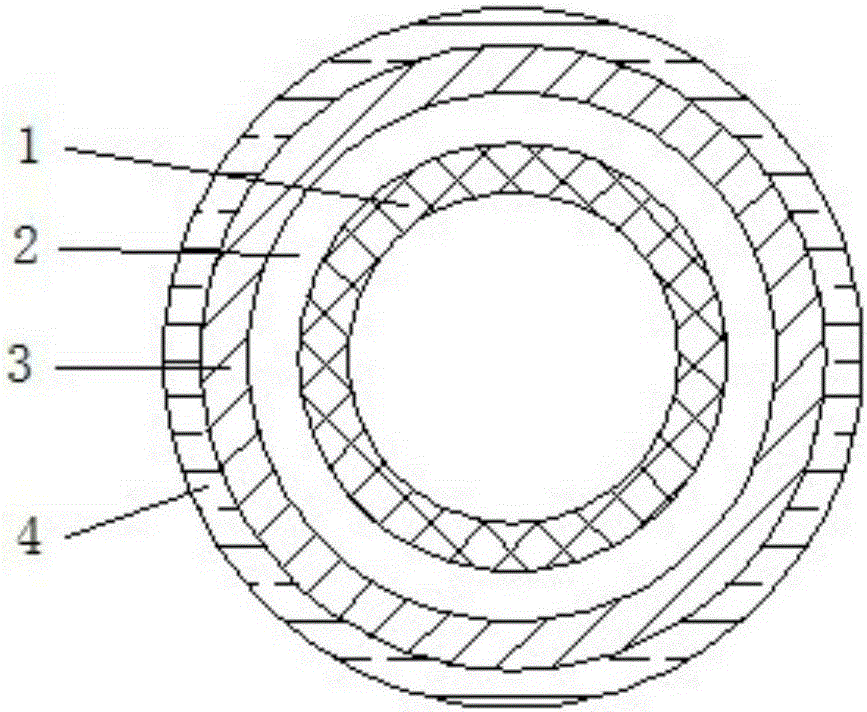

[0016] see figure 1 , with reference to figure 2 , image 3 , The fireproof and high temperature resistant vacuum insulation gloves of the present invention are provided with a high temperature resistant layer 4, a heat radiation resistant layer 3, a vacuum layer 2 and a heat insulating layer 1 sequentially from the outside to the inside.

[0017] The high-temperature-resistant layer in the present invention is made of heat-insulating and heat-preserving paint capable of withstanding a high temperature of 1800°C. The high temperature resistant layer can directly face the flame heat insulation, besides high temperature resistance, it can also effectively suppress and shield the infrared radiant heat and heat conduction, the heat insulation suppression efficiency can reach about 90%, and the coating thickness is only a few millimeters .

[0018] The heat radiation resistant layer in the present invention is made of aluminum foil heat radiation resistant material. It can mee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com