Adhesive composition, adhesive film, brightness enhancement film, and backlight unit comprising same

A composition and adhesive technology, applied in the directions of non-polymer adhesive additives, adhesives, optical components, etc., can solve problems such as light leakage and quantum dot damage, and achieve small performance deviation, high applicability, and excellent luminous efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] 5 g of polyisobutylene, 3 g of hydrogenated dicyclopentadiene (DCPD) based adhesive, 1.9 g of trimethylolpropane triacrylate (TMPTA), 0.1 g of photoinitiator IGR 184, and 30 g of toluene were mixed to prepare an adhesive agent composition.

[0102] 1% by weight of CdSe / ZnS red quantum dots was added relative to the total weight of the adhesive composition (excluding the solvent of the adhesive composition), and ultrasonic treatment was performed for 30 minutes to uniformly mix the quantum dots. Thereafter, the adhesive composition was coated on a polyethylene terephthalate (PET) film by bar coating. In order to completely remove toluene contained in the adhesive composition, a PET film which was easily removed after being heated in an oven at 100° C. for 10 minutes was laminated on the adhesive coating. In a UV curing machine (D-lamp), subject the film to about 1,000 mJ / cm 2 Next solidify.

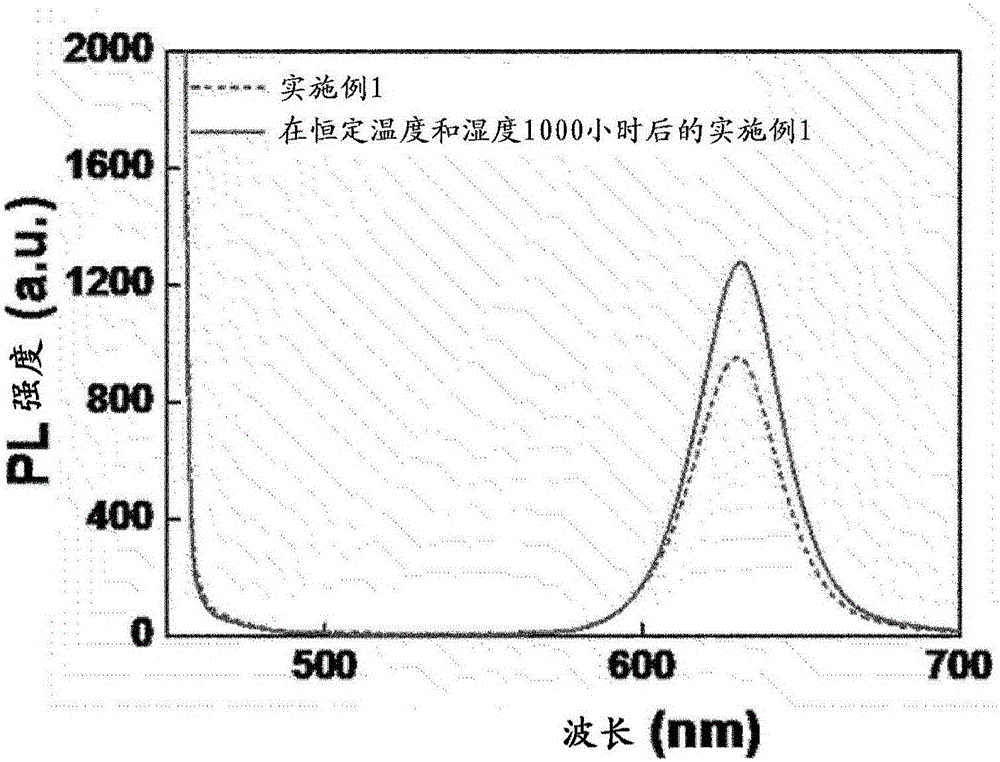

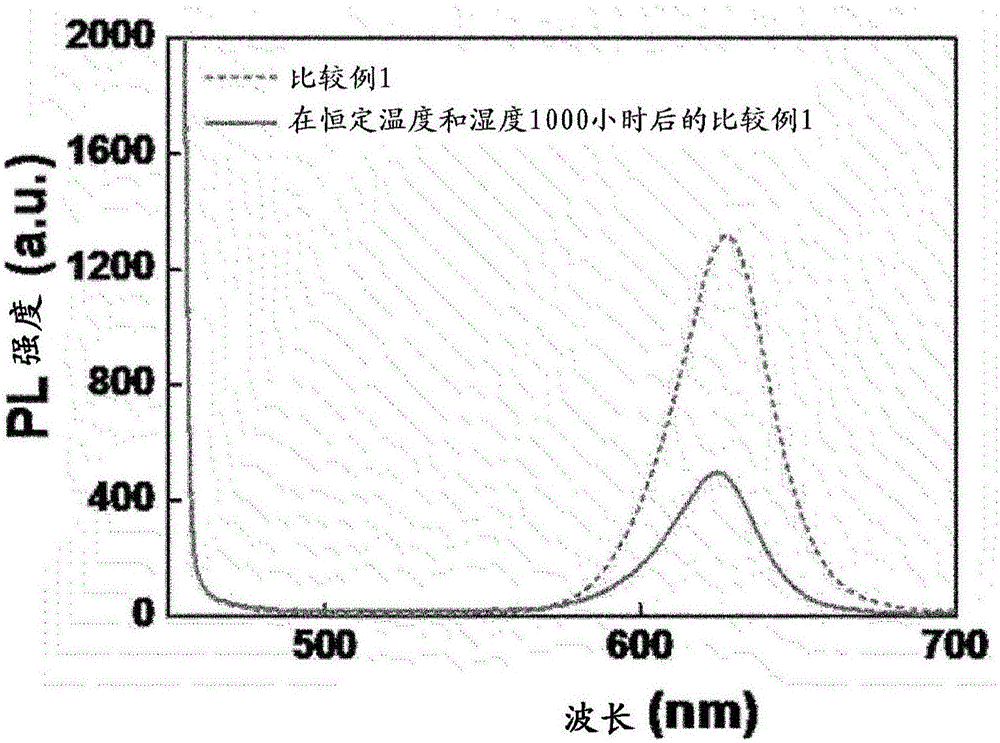

[0103] Furthermore, in order to examine the dispersion of quantum dots in th...

Embodiment 2

[0111] Except for using CdSe / ZnS green quantum dots, an adhesive film was prepared by the same method as in Example 1, and then in order to examine the dispersion of quantum dots in the adhesive film, the dispersion was measured by a fluorescence microscope.

Embodiment 3

[0116] 50 mg polyethylene wax (PED 191, Clarient) was subdivided into 20 ml vials and the solution added with 4.95 g toluene was heated to 90°C. The polyethylene wax was adjusted to a concentration of 1% by weight relative to the solution.

[0117] As soon as the solution reached 90 °C, inject the CdSe / ZnS red quantum dot solution at an appropriate concentration (standard: 25 mg / ml toluene), and place the vial in a 50 °C water bath with a preset temperature and stir it by using a stirring bar at 200 rpm. Stir for 1 minute. After 1 minute the vial was removed from the water bath and left in air for 4 minutes, and the stir bar was removed. The vial was left to stand until completely cooled, then 20 g was collected and divided into conical tubes and centrifuged at 3,000 rpm for 5 minutes to wash. After centrifugation, discard the supernatant and pour the same volume of toluene into the precipitated microcapsules and redisperse by vortexing. Repeat the washing process three mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com