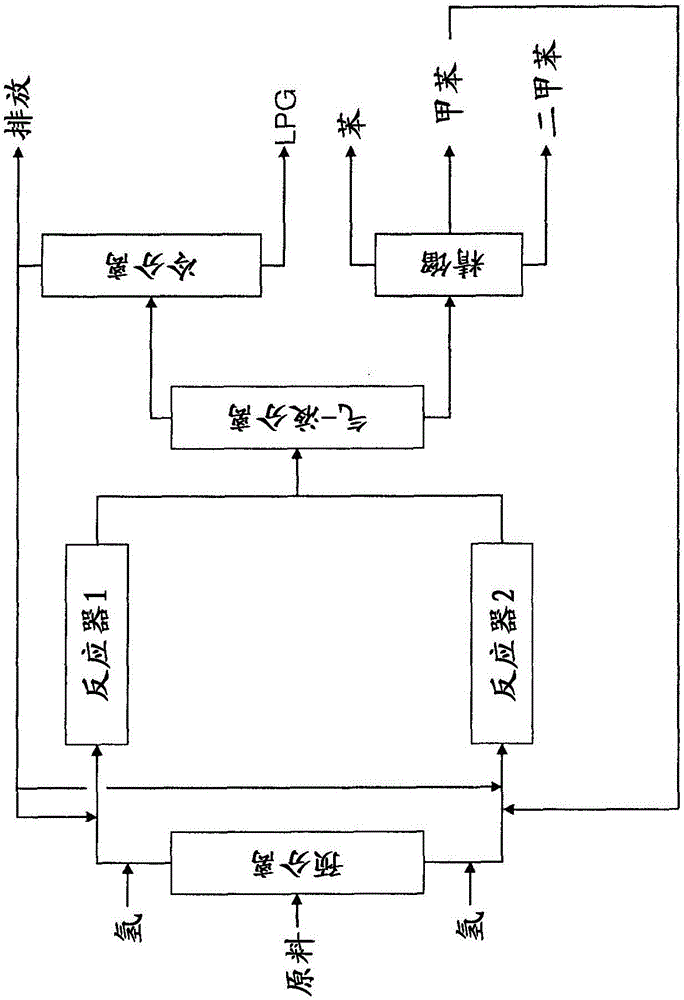

Process for producing benzene from a c5-c12 hydrocarbon mixture

A C5-C12, logistics technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, hydrocarbons, hydrocarbons, etc., can solve the problem of limited ratio control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

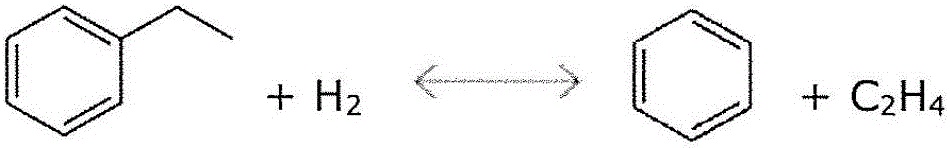

[0122] Two-stage hydrotreated pyrolysis gasoline having the composition shown in Table 1 was fed to a reactor containing a hydrocracking catalyst deposited on ZSM-5 with 0.03 wt% Pt, wherein the ZSM-5 The SiO2 / Al2O3 ratio was 80. Process conditions are 476°C, 200psig, H2 / HC=3, WHSV=2hr -1 . The composition of the resulting product stream is given in Table 1 below.

[0123] The benzene in the product stream is extremely pure, ie, substantially free of benzene azeotropes.

[0124] However, the amount of benzene in the product stream is no greater than in the source feed stream. Large quantities of alkylbenzenes, especially toluene and xylenes, are obtained.

[0125] Table 1

[0126] Raw materials (wt%) Product (wt%) benzene 48.11 47.75 Cyclohexane 2.87 0.01 toluene 16.03 19.22 mixed xylenes 2.83 2.85 Ethylbenzene 5.61 0.11 trimethylbenzene 0.03 0.03 Benzene purity 71.14% 99.96%

[0127] In Table 1-4, the pu...

Embodiment 2

[0128] Embodiment 2: benzene-rich stream

[0129] A feedstock having the composition shown in Table 2 was fed into a reactor containing a hydrocracking catalyst having the same composition as the catalyst used in Example 1. The process conditions are 470°C, 200psig, H2 / HC=1, WHSV=3hr -1 . The composition of the resulting product stream is given in Table 2 below.

[0130] This example demonstrates that hydrocracking a source feedstream containing significant amounts of benzene will result in some loss of benzene, but yield reagent grade BTX from which a significant amount of reagent grade benzene can be obtained.

[0131] Table 2

[0132] Raw materials (wt%) Product (wt%) benzene 75.36 71.57 Cyclohexane 0 0.01 toluene 0 3.13 mixed xylenes 0 0.18 Ethylbenzene 0 0.25 trimethylbenzene 0 0.01 Benzene purity 78.91% 99.83%

Embodiment 3

[0133] Embodiment 3: lean benzene stream

[0134] A feedstock having the composition shown in Table 3 was fed into a reactor containing a hydrocracking catalyst having the same composition as the catalyst used in Example 1. The process conditions are 450°C, 200psig, H2 / HC=1, WHSV=3hr -1 . The composition of the resulting product stream is given in Table 3 below.

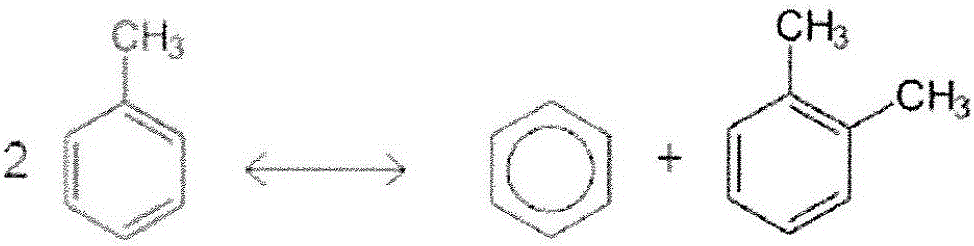

[0135] This example describes the effect of hydrocracking a low benzene feedstock stream. It can be seen that a large amount of toluene is converted to benzene and toluene by toluene disproportionation.

[0136] table 3

[0137] Raw materials (wt%) Product (wt%) benzene 0 8.88 Cyclohexane 0 0 toluene 100 78.25 mixed xylenes 0 11.26 Ethylbenzene 0 0.01 trimethylbenzene 0 0.05 Benzene purity - 99.96%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com