Hygroscopic laminate with hygroscopic film

A laminate, hygroscopic technology, applied in the direction of layered products, electric solid devices, semiconductor devices, etc., can solve the problems of reduced power generation efficiency, deterioration of solar cell elements, etc., and achieve the effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

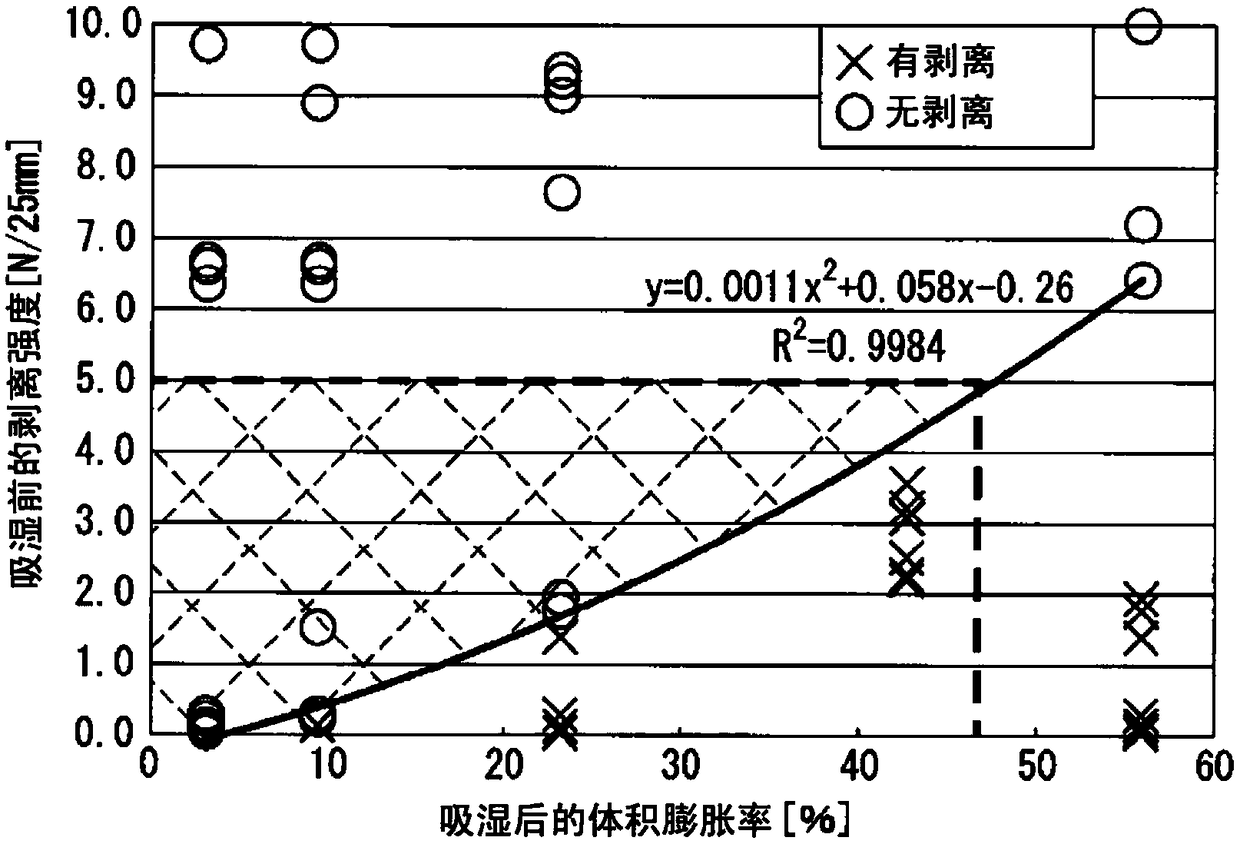

[0077] "Sample Production"

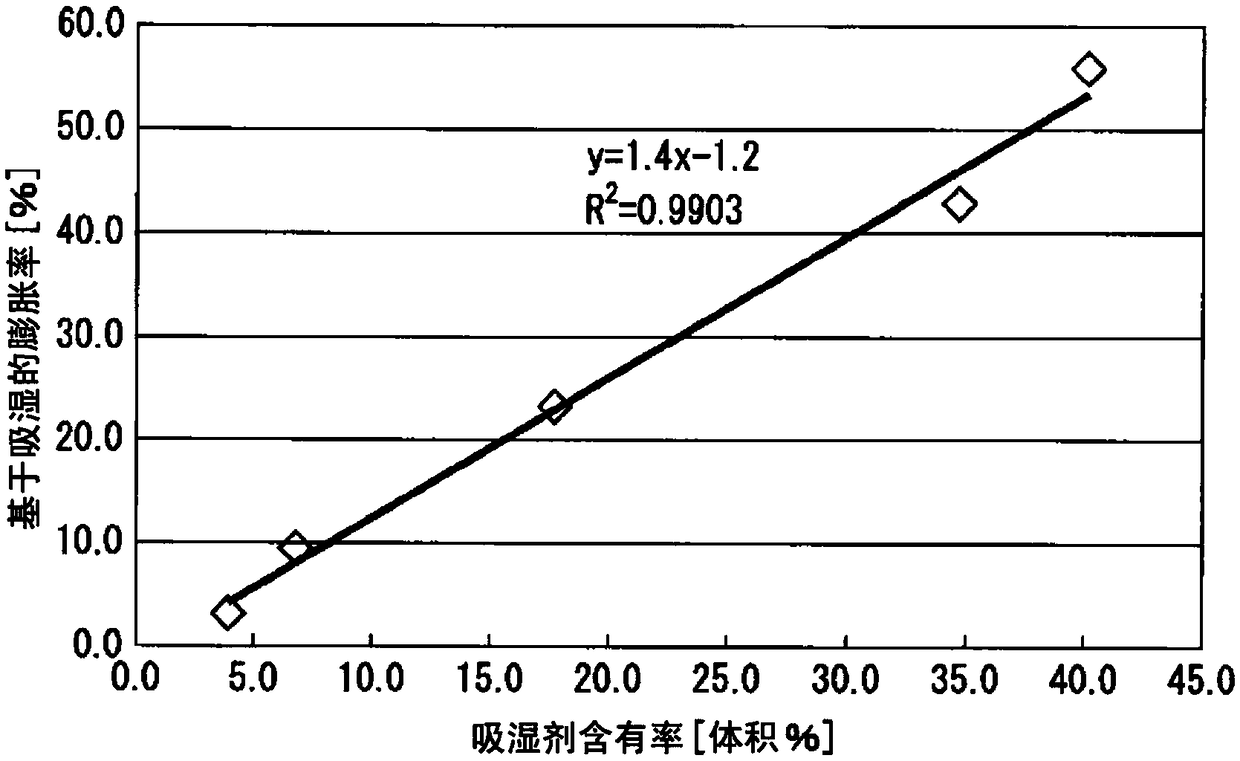

[0078] LDPE (product name: Petrocene 202R, manufactured by TOSOH CORPORATION, melt flow rate: 24g / 10min, melting point: 106°C) as a thermoplastic resin binder and calcium oxide (CaO, density: 3.35g) as a chemical adsorbent / cm 3 ) is kneaded so that the calcium oxide content is 4 to 40% by volume to obtain a hygroscopic composition. Kneading was performed using LABO PLASTOMILL (manufactured by Toyo Seiki Seisakusho Co., Ltd.).

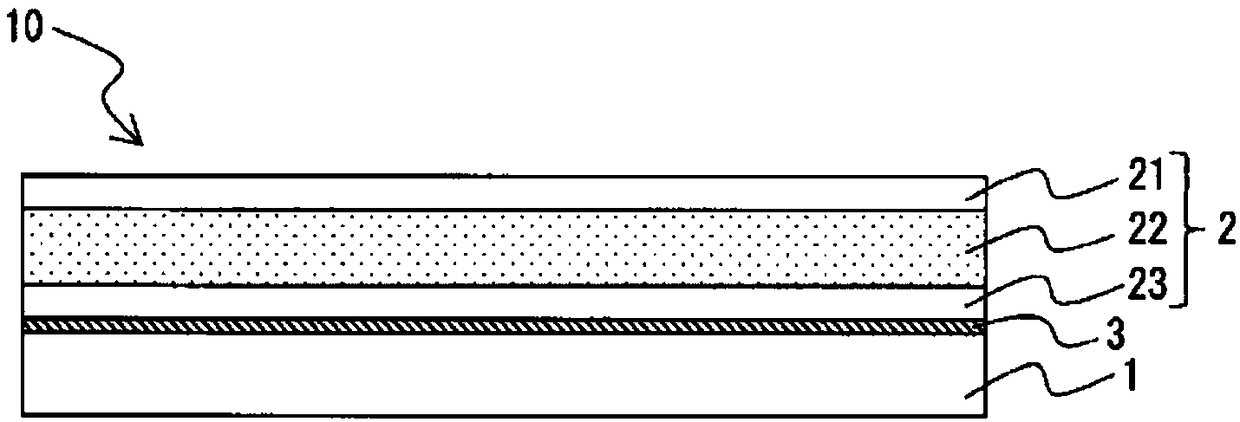

[0079] LLDPE (product name: EVOLUE-SP2520, manufactured by Prime Polymer Co., Ltd., melt flow rate: 1.9 g / 10 minutes, melting point: 122° C. ). Using a three-layer co-extrusion T-die, the above-mentioned hygroscopic composition and the resin for the skin layer were formed into a film so that the thickness of the hygroscopic layer was 40 μm, and the thickness of the front and back skin layers was 10 μm, respectively, to obtain a hygroscopic film.

[0080] The acrylic adhesive was coated on the hygroscopic film with a wir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com