A data center cabinet and its pressure spraying system

A data center and spray system technology, applied in data centers, cooling/ventilation/heating renovation, circuits, etc., can solve problems such as cooling of large server cabinets, and achieve the effects of constant pressure, large specific heat, and uniform flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

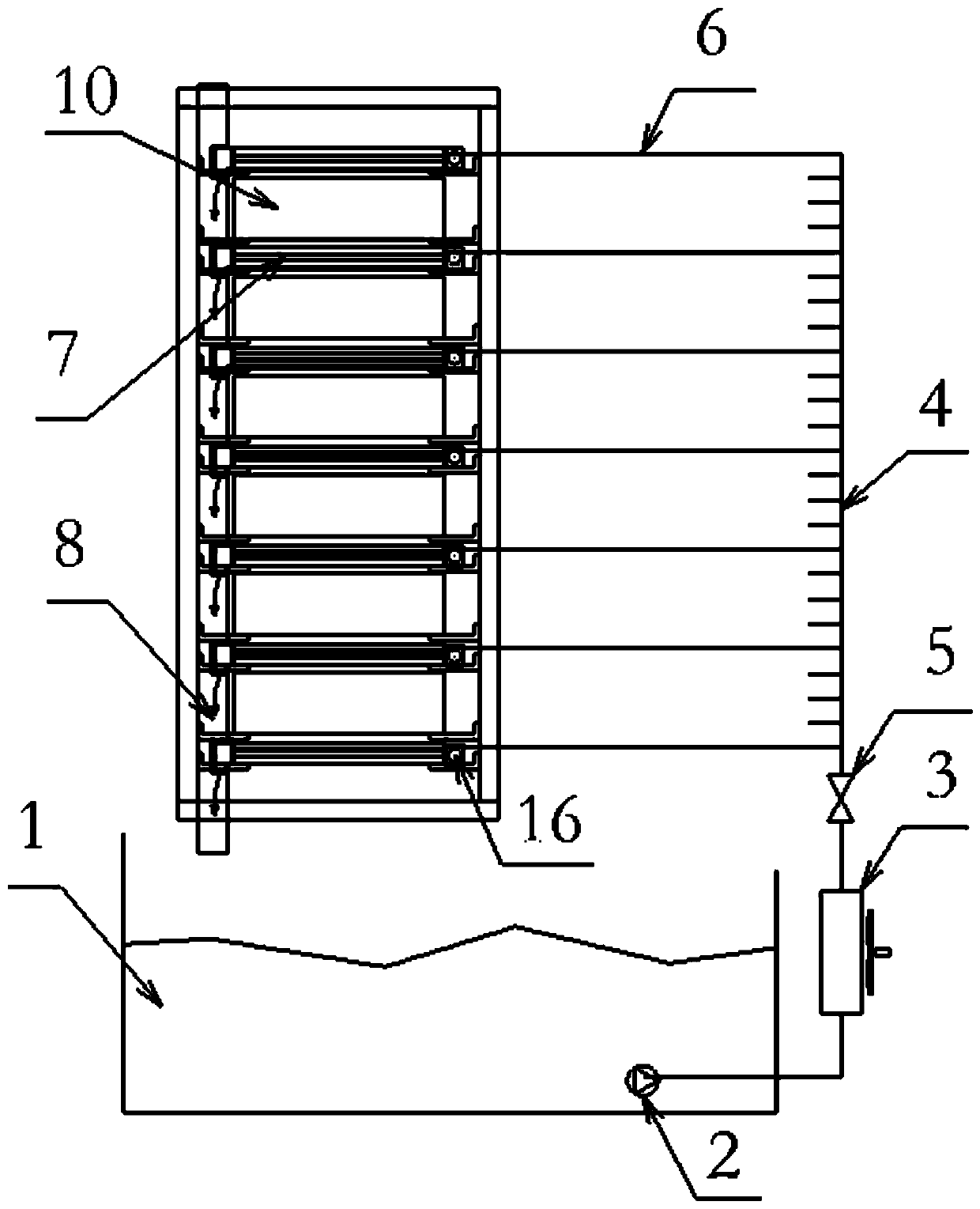

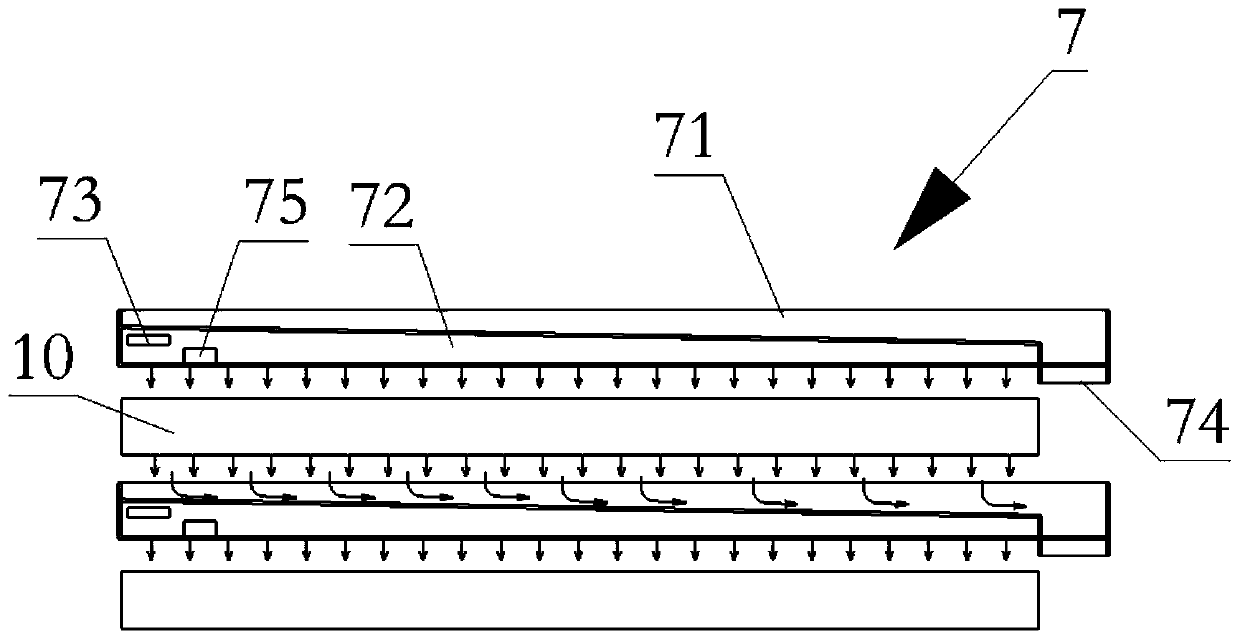

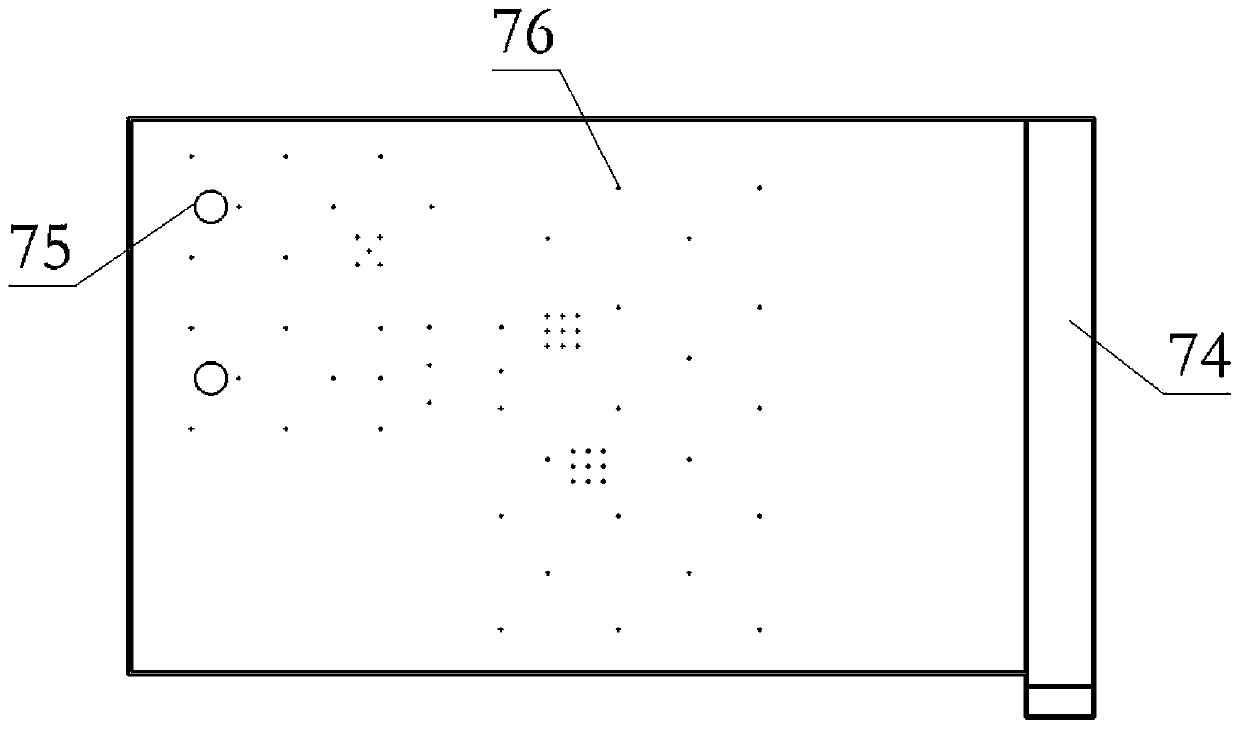

[0033] refer to Figure 1-8 As shown, a data center cabinet pressure sprinkler system, such as figure 1 , including main oil tank 1, pump 2, radiator 3, data center cabinet, oil inlet device 6, oil return device 8, cooling liquid oil, the main oil tank 1, pump 2, radiator 3, data center The tank is connected into a closed oil circuit through the oil inlet device 6 and the oil return device 8; the pump 2 pumps the cooling liquid oil out of the main oil tank 1, and exchanges heat through the radiator 3 and enters the oil circuit through the pipeline. In the oil separation device 4 in the data center cabinet described above; the pressure separation of the oil separation device 4 into the liquid distributor 7, and the liquid distribution device 7 distributes liquid and sprays to cool the server; The cooling liquid oil after the cooling...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap