Equipment for soaking cells

A battery cell and equipment technology, which is applied in the field of soaking battery cell equipment, can solve problems such as low production efficiency, uneven electrolyte distribution, damage, etc., and achieve the effect of improving the soaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

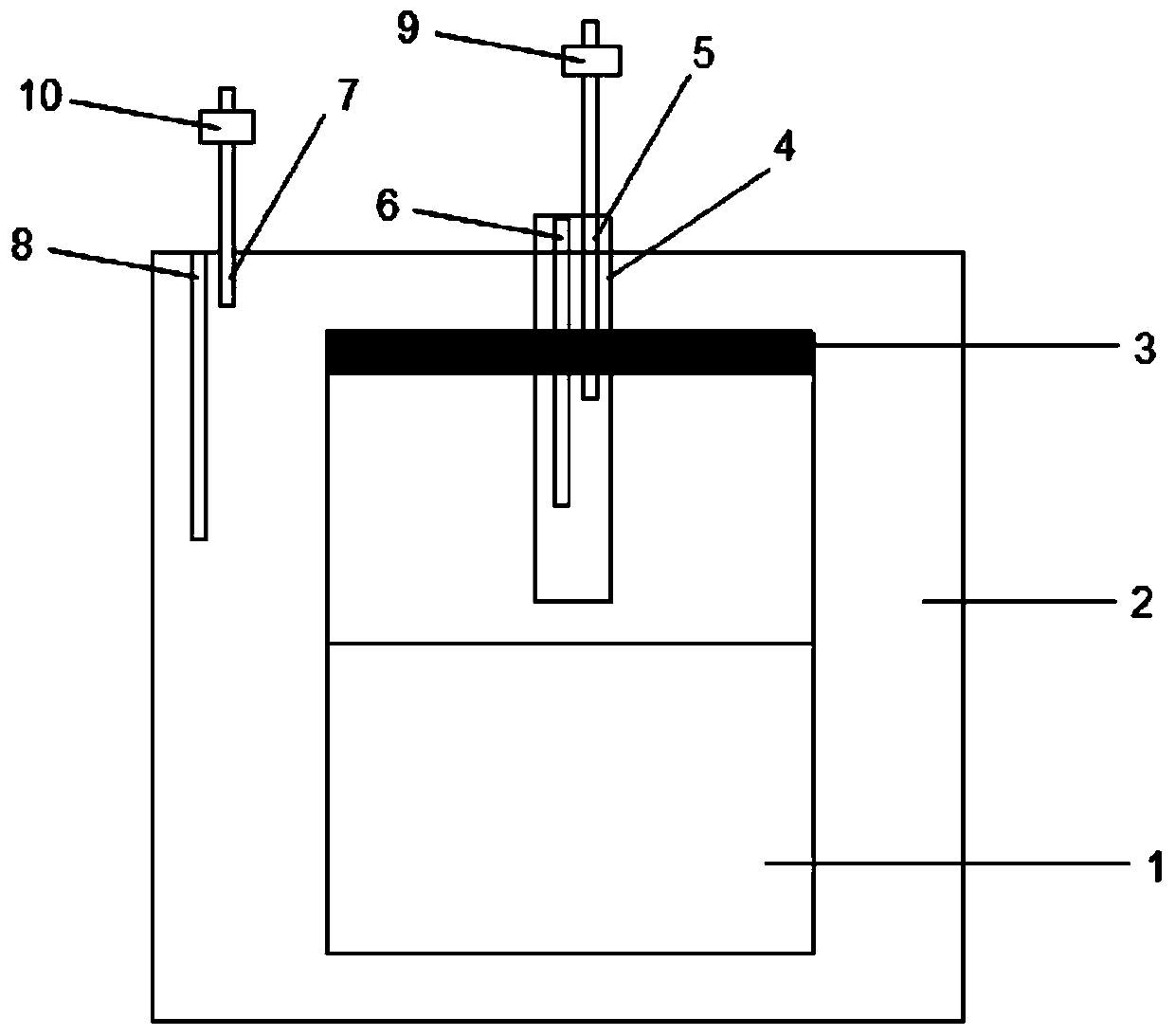

[0057] Step 1. Put the battery cell 1 that has been injected into the cavity 2, put the air bag of the battery cell 1 on the sleeve 4 and fix it with the seal 3;

[0058] Step 2: Pressurize the cavity 2 to 100KPa through the dry compressed nitrogen gas inlet 8, vacuumize the inside of the cell to -60KPa through the conduit 5, close the valve 9, and let it stand for 10 minutes;

[0059] Step 3: Open the valve 10 to restore the normal pressure in the cavity 2, inject dry nitrogen into the cell 1 airbag through 6 to pressurize to 100KPa, and let it stand for 10 minutes;

[0060] Step 4: pressurize the cavity 2 to 100KPa through the dry compressed nitrogen gas inlet 8, vacuumize the interior of the cell to 100KPa through the conduit 5, close the valve 9, and let it stand for 10 minutes;

[0061] Step 5. Open the valve 10 to restore the normal pressure in the cavity 2, inject dry nitrogen into the cell 1 airbag through 6 to pressurize to 100KPa, and let it stand for 10 minutes;

...

Embodiment 2

[0065] Step 1. Put the battery cell 1 that has been injected into the cavity 2, put the air bag of the battery cell 1 on the sleeve 4 and fix it with the sealing clip 3;

[0066] Step 2: Pressurize the cavity 2 to 300KPa through the dry compressed nitrogen gas inlet 8, vacuumize the interior of the cell to -60KPa through the conduit 5, close the valve 9, and let it stand for 30 minutes;

[0067] Step 3: Open the valve 10 to restore normal pressure in the cavity 2, inject dry nitrogen into the cell 1 airbag through 6 to pressurize to 300KPa, and let it stand for 30 minutes;

[0068] Step 4: Pressurize the cavity 2 to 100KPa through the dry compressed nitrogen gas inlet 8, vacuumize the interior of the cell to -100KPa through the conduit 5, close the valve 9, and let it stand for 30 minutes;

[0069] Step 5. Open the valve 10 to restore the normal pressure in the chamber 2, inject dry nitrogen into the cell 1 airbag through 6 to pressurize to 300KPa, and let it stand for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com