Fluorine-containing ion exchange membrane for fuel cell and preparation method of fluorine-containing ion exchange membrane

An ion exchange membrane and fuel cell technology, which is applied in the field of fluorine-containing ion exchange membranes for fuel cells and their preparation, and can solve the problems of affecting the mechanical properties of membranes and reducing the molecular weight of resins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

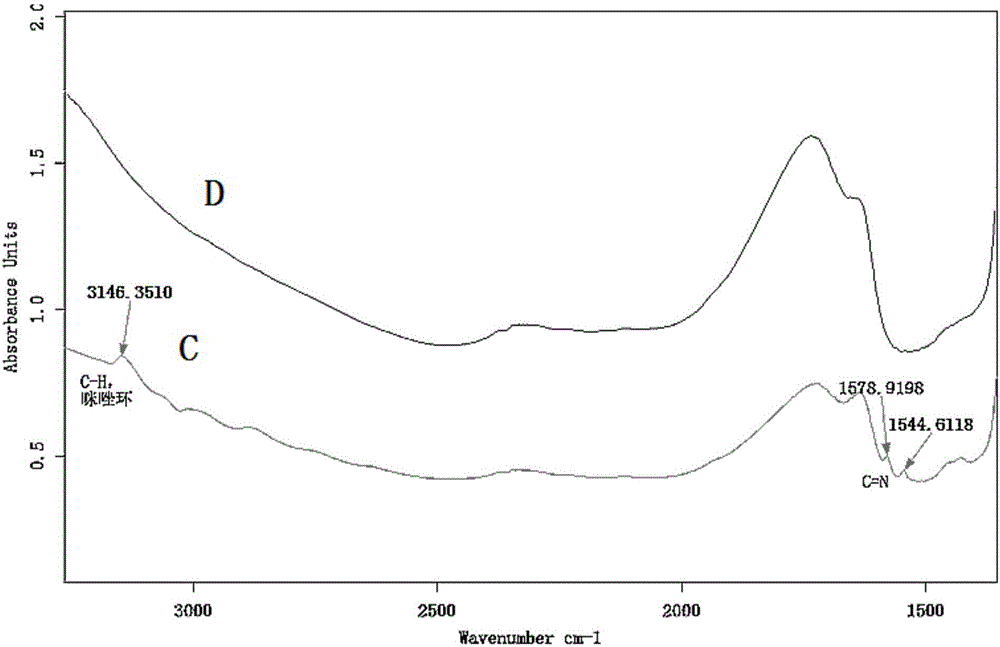

[0028] In this embodiment, 1-vinylimidazole is grafted by the ATRP method, and the specific implementation steps are as follows:

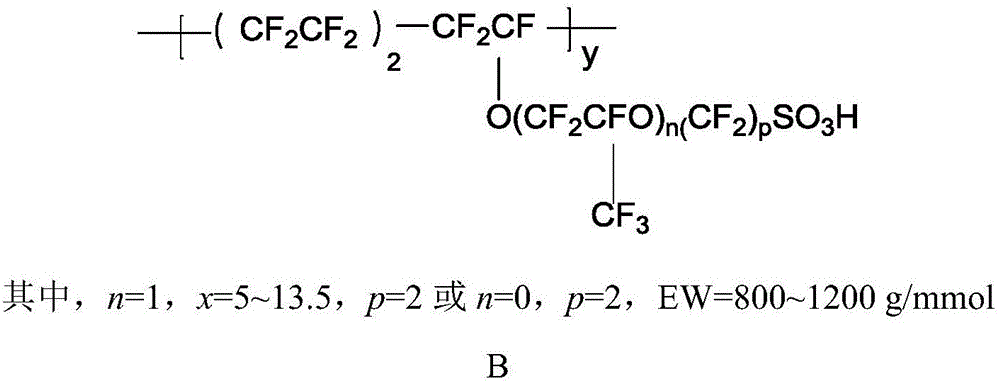

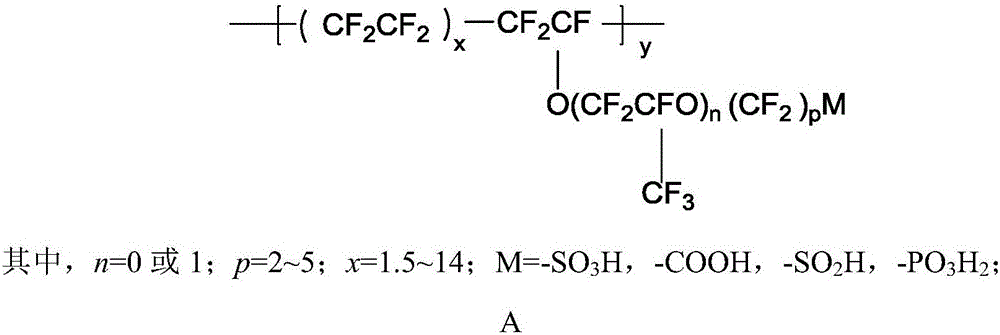

[0029] (a) Disperse the long-chain perfluorinated ion exchange resin (n=1, p=2, EW=900g / mmol) in an aqueous solution of n-propanol (the mass ratio of n-propanol to water is 1:1), The resin concentration is 10wt%, and the solution quality is 100g.

[0030] (b) Weigh 10 g of 1-vinylimidazole monomer and 0.6 g of 2,2'-bipyridyl ligand into the solution prepared in (a).

[0031] (c) Deoxygenate the solution in (b), quickly add 0.1 g of CuBr catalyst, and deoxygenate to less than 5 ppm by freezing and pumping in liquid nitrogen.

[0032] (d) The solution in (c) was reacted at 80°C.

[0033] (e) The solution after the reaction in (d) is subjected to ion exchange, dialysis, and drying to obtain a film-forming resin.

[0034](f) the film-forming resin in (e) is dispersed in the aqueous solution of ethanol (solid content 5~50%), add a certain amount of m...

Embodiment 2

[0038] In this embodiment, 4-vinylbenzo-18-crown-6 monomer is grafted on perfluorosulfonic acid resin by ATRP method, and the specific implementation steps are as follows:

[0039] (a) Disperse the short-chain perfluorosulfonic acid ion exchange resin (n=0, p=2, EW=800g / mmol) in DMF, the resin concentration is 10wt%, and the solution mass is 100g.

[0040] (b) Weigh 10 g of 4-vinylbenzo-18-crown-6 monomer and 0.6 g of 2,2'-bipyridine ligand into the solution prepared in (a).

[0041] (c) Deoxygenate the solution in (b), quickly add 0.1 g of CuBr catalyst, and deoxygenate to less than 5 ppm by freezing and pumping in liquid nitrogen.

[0042] (d) The solution in (c) was reacted at 80°C.

[0043] (e) The solution after the reaction in (d) is subjected to ion exchange, dialysis, and drying to obtain a film-forming resin.

[0044] (f) the film-forming resin in (e) is dispersed in the aqueous solution of ethanol (solid content 5~50%), add a certain amount of lanthanum ion compoun...

Embodiment 3

[0046] In this embodiment, 4-[2,4-(5-methyl-2-benzoxazolyl)phenyl]vinylbenzoic acid methyl ester monomer is grafted on the perfluorosulfonic acid resin by ATRP method, and the specific implementation Proceed as follows:

[0047] (a) Disperse the long-chain perfluorosulfonic acid resin (n=1, p=2, EW=900g / mmol) in DMSO, the resin concentration is 5wt%, and the solution mass is 100g.

[0048] (b) Weigh 30g of 4-[2,4-(5-methyl-2-benzoxazolyl)phenyl]vinylbenzoic acid methyl ester monomer, 0.6g of 2,2'-bipyridine The ligand is added to the solution prepared in (a).

[0049] (c) Deoxygenate the solution in (b), quickly add 0.1 g of CuBr catalyst, and deoxygenate to less than 5 ppm by freezing and pumping in liquid nitrogen.

[0050] (d) The solution in (c) was reacted at 80°C.

[0051] (e) The solution after the reaction in (d) is subjected to ion exchange, dialysis, and drying to obtain a film-forming resin.

[0052] (f) the film-forming resin in (e) is dispersed in the aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com