Flexible electrode material and preparation method and application thereof

A flexible electrode, active material technology, applied in battery electrodes, hybrid capacitor electrodes, non-aqueous electrolyte battery electrodes, etc. Development and other issues, to achieve the effect of improving electrical conductivity, easy operation, and improving heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

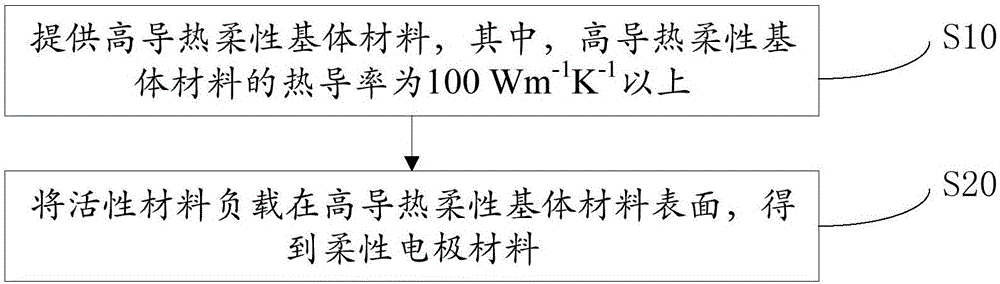

[0030] Such as figure 1 Shown, also provide the preparation method of the above-mentioned flexible electrode material of an embodiment, comprise the following steps:

[0031] S10. Provide a flexible base material with high thermal conductivity, wherein the thermal conductivity of the flexible base material with high thermal conductivity is 100Wm -1 K -1 above.

[0032] Specifically, the high thermal conductivity flexible base material can be a high thermal conductivity graphene film or a high thermal conductivity graphite film.

[0033] Among them, the high thermal conductivity graphene film is prepared by the following method: graphene is prepared by electrochemical exfoliation or graphene oxide is prepared by chemical oxidation exfoliation, and the graphene film or graphene oxide film is obtained by suction filtration or casting film forming process, and the Heat treatment to obtain a graphene film with high thermal conductivity.

[0034] Specifically, the preparation me...

Embodiment 1

[0049] Electrochemical exfoliation of graphite rods to prepare graphene. Use high-purity graphite rod as working electrode, platinum sheet as counter electrode, 0.1MNa 2 WO 4 The aqueous solution is the electrolyte, and the working voltage is 10V. After the stripping is complete, wash, ultrasonic, and centrifuge to collect few-layer graphene;

[0050] Dispersing the above-mentioned graphene in the organic solvent DMF, adopting the method of suction filtration, obtains the graphene film;

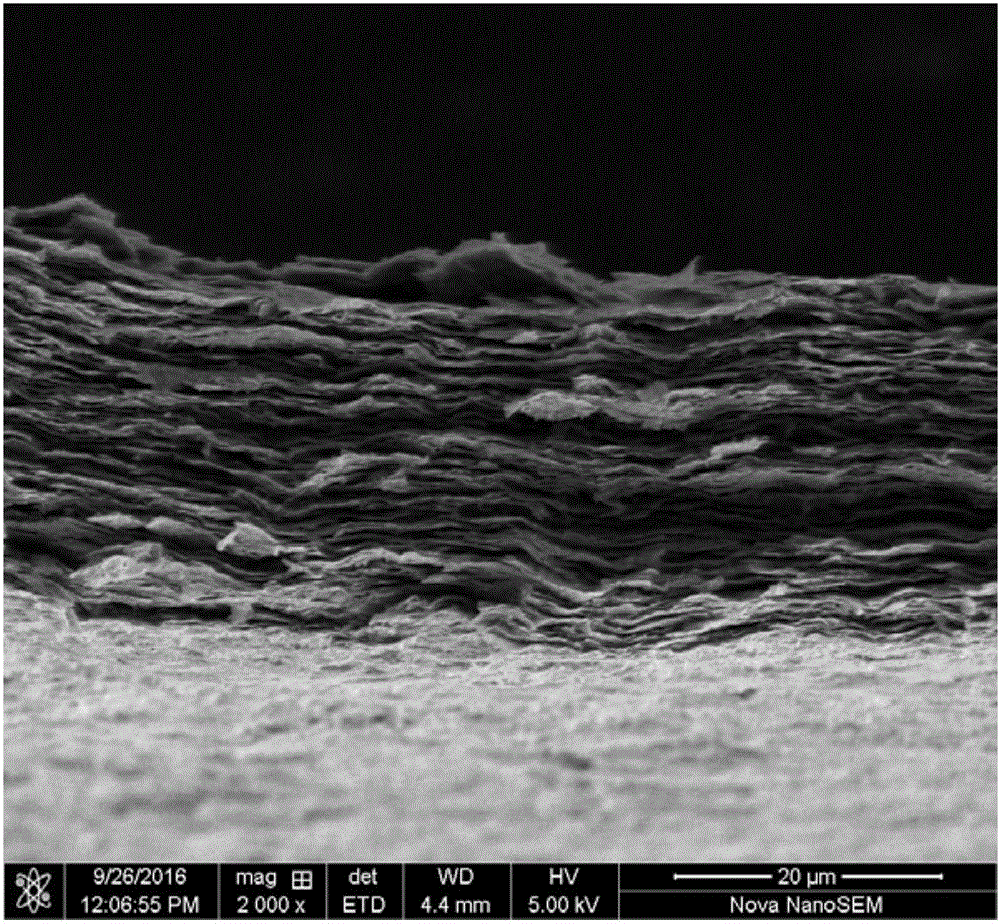

[0051] Using 5% H 2 -Heat treatment of graphene film in Ar atmosphere, heating rate 5°C / min, heat preservation at 900°C for 2h, and natural cooling to obtain graphene film with high thermal conductivity. The scanning electron microscope image of the graphene film with high thermal conductivity is as follows figure 2 Shown; The thermal conductivity of this high thermal conductivity graphene film is as shown in table 1.

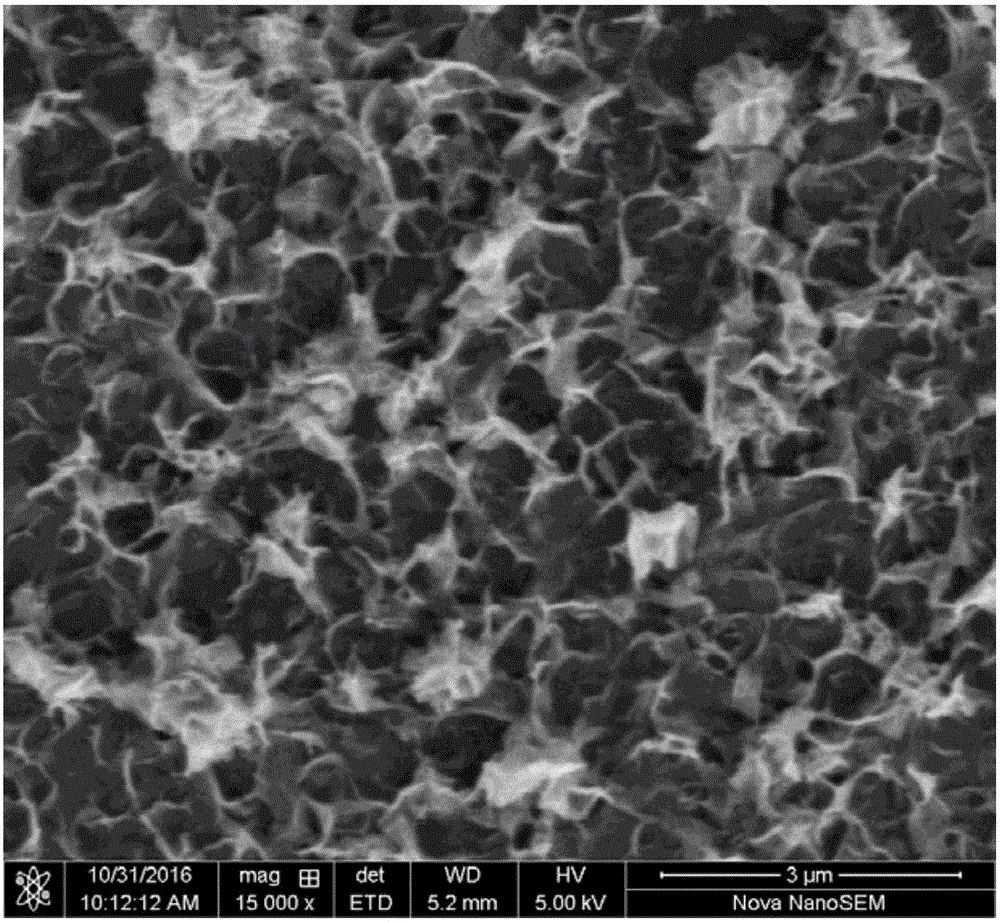

[0052] Electrodeposition of ternary cobalt nickel sulfide (CoNi 2 S...

Embodiment 2

[0057] Improve the Hummers method to prepare graphene oxide. After chemical exfoliation, washing, and freeze-drying, prepare an aqueous solution of graphene oxide with a concentration of 3 mg / mL;

[0058] Using copper foil as the substrate, the above graphene oxide solution is evenly cast on the surface of the copper foil, left to stand, and dried at 50°C to form a film;

[0059] Using high temperature heat treatment, 10%H 2 -Ar atmosphere, heating rate 10°C / min, heat preservation at 1000°C for 1h, natural cooling to obtain high thermal conductivity graphene film;

[0060] Electrodeposited polyaniline in three-electrode system, high thermal conductivity graphene film as working electrode, reference electrode as saturated calomel electrode, counter electrode as platinum sheet, and electrolyte composition as 0.5M H 2 SO 4 and 0.2M aniline solution. The electrochemical cyclic voltammetry scan was performed on the electrochemical workstation, the voltage range was from -0.2V to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com