Disc pelletizing intelligent production system and control method thereof

A disc ball making and production control technology, applied in general control systems, control/regulation systems, program control in sequence/logic controllers, etc. Production efficiency and other issues to achieve the effect of improving product quality and improving the pass rate of green balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the drawings and specific embodiments, but the following embodiments do not limit the present invention in any way.

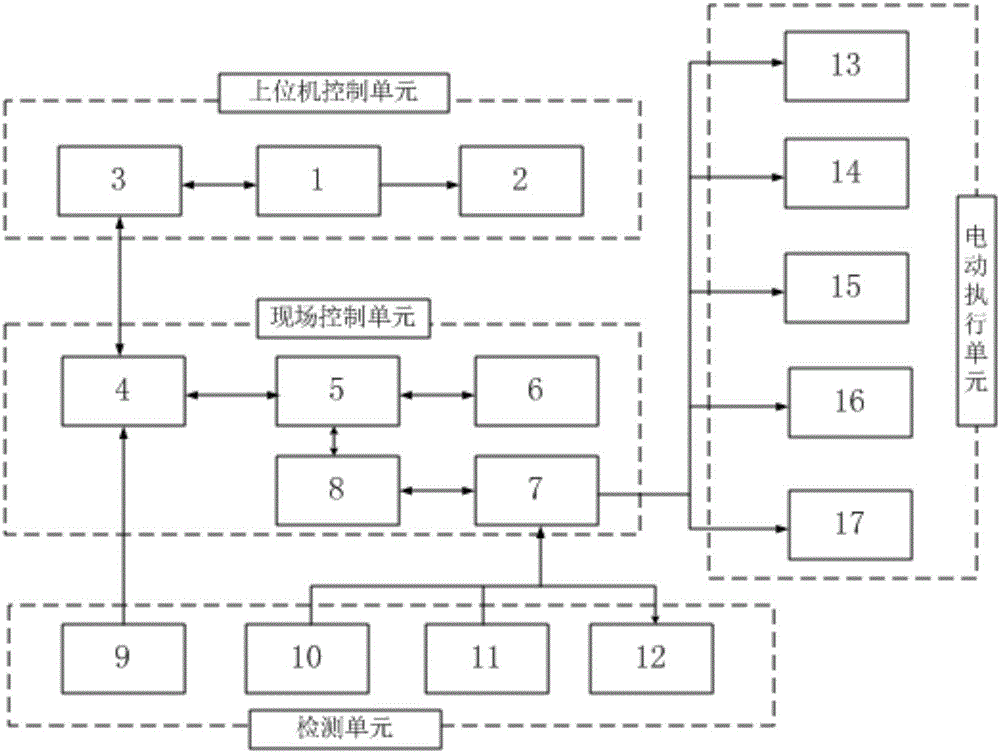

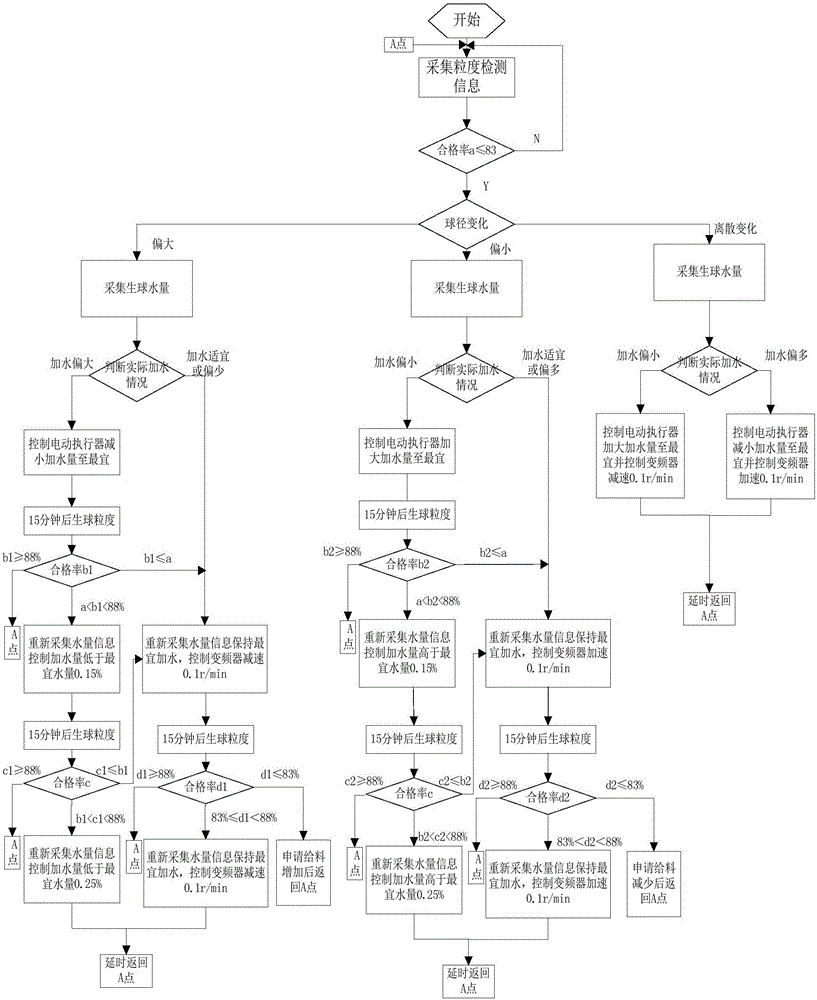

[0064] An intelligent production control system for disc pelletizing used with the disc pelletizing device, such as figure 1 As shown, the disc pelletizing intelligent production control system includes a host computer control unit, a field control unit, a detection unit, and an electric execution unit; wherein the host computer control unit includes a second optical fiber transceiver that is arranged in the control room and connected in sequence 3. High-speed processing server 1 and display 2; the field control unit includes the first optical fiber transceiver 4, the switch 5, the touch screen 6, the programmable logic controller 7 and the MPI-ETH converter 8; the detection unit includes the particle size detection device 9, Infrared moisture detector 10, electromagnetic flow meter 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com