Power line insulation resistance test method and tester insulation support

A technology for insulation resistance testing and power lines, applied in high resistance measurement, measuring resistance/reactance/impedance, instruments, etc., can solve problems such as water accumulation, poor insulation conditions, and high risk of personal electric shock for operators, so as to protect personal safety Safety and the effect of preventing electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

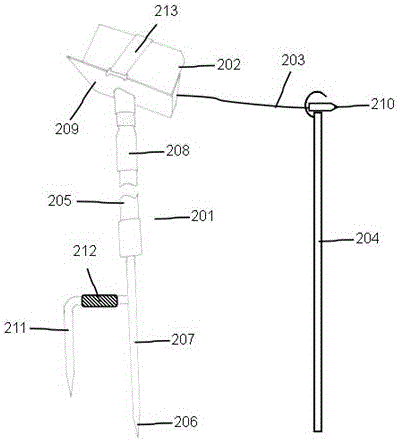

[0030] Embodiment 1: as figure 1 As shown, a method for testing the insulation resistance of a power line includes that the test method requires at least two testers to operate, wherein one tester observes the insulating bracket 201 to support the test instrument 202, and the other tester uses an insulating operating rod to insulate 204 Connect the meter probe 210 connected to the meter wire 203 to the fault test point. 102

[0031] Because adopting said test method requires at least two testers to operate, one of them observes the insulating support to support the test instrument, and the other tester insulates and uses an insulating operating rod to connect the instrument probe connected to the instrument line to the fault test point. When using the insulation support of the insulation resistance tester, the operator should wear insulating boots and gloves. Two people operate, one observes the instrument, and pays attention not to touch the instrument and the instrument lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com