Side over fire air distribution method and coal-fired boiler

A technology of coal-fired boilers and burn-out air, which is applied in the combustion method, combustion air/fuel supply, combustion equipment, etc., can solve the problems of large combustion heat loss, poor unit operation economy, high temperature corrosion of water cooling walls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

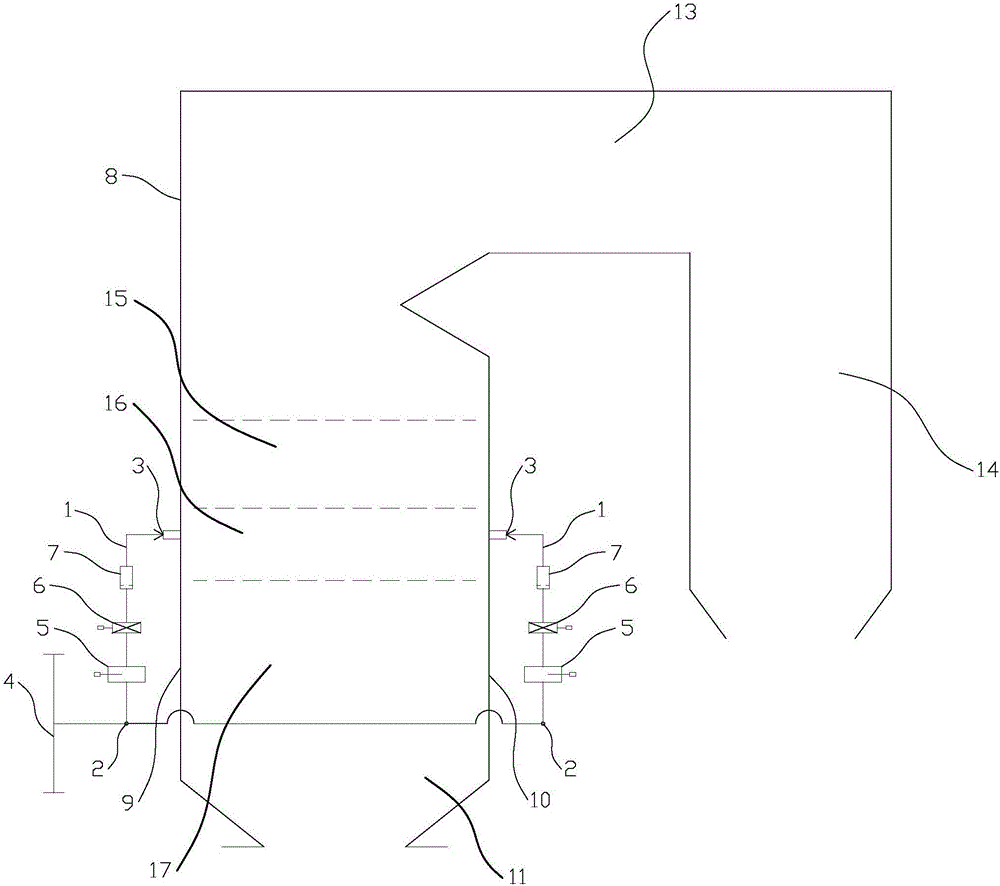

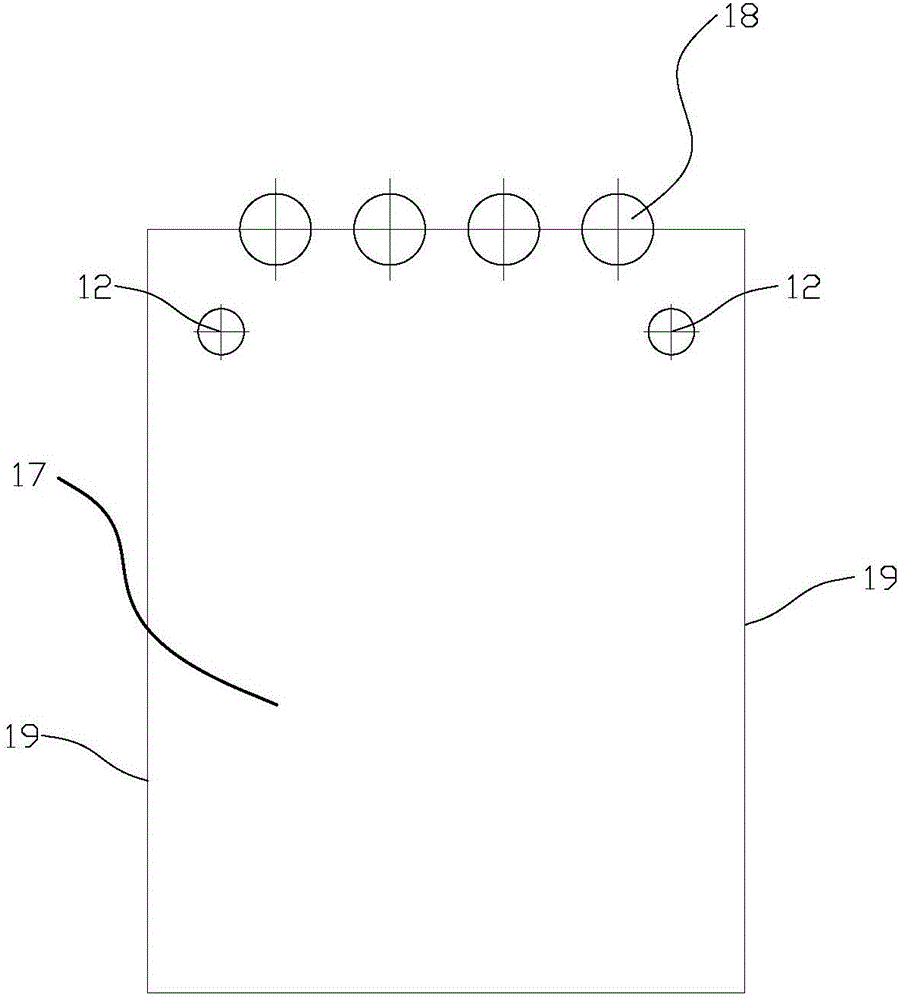

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] A method for distributing side overburned air, comprising supplying air to the side overburned air area of a coal-fired boiler through an air supply duct, the air source of the air supply duct comes from the hot primary air in the hot primary air main pipe. The air distribution method of the present invention uses the hot primary air in the hot primary air main pipe as the air source to supply air to the side burnout air area of the coal-fired boiler. Compared with the existing secondary air, the hot primary air has a significantly higher wind speed, The pressure of the hot primary air can even reach 2 to 3 times that of the original secondary air. There is no need to add additional booster equipment to increase the wind pressure and wind speed on the air supply pipeline. The hot primary air from the hot primary air main pipe can be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com