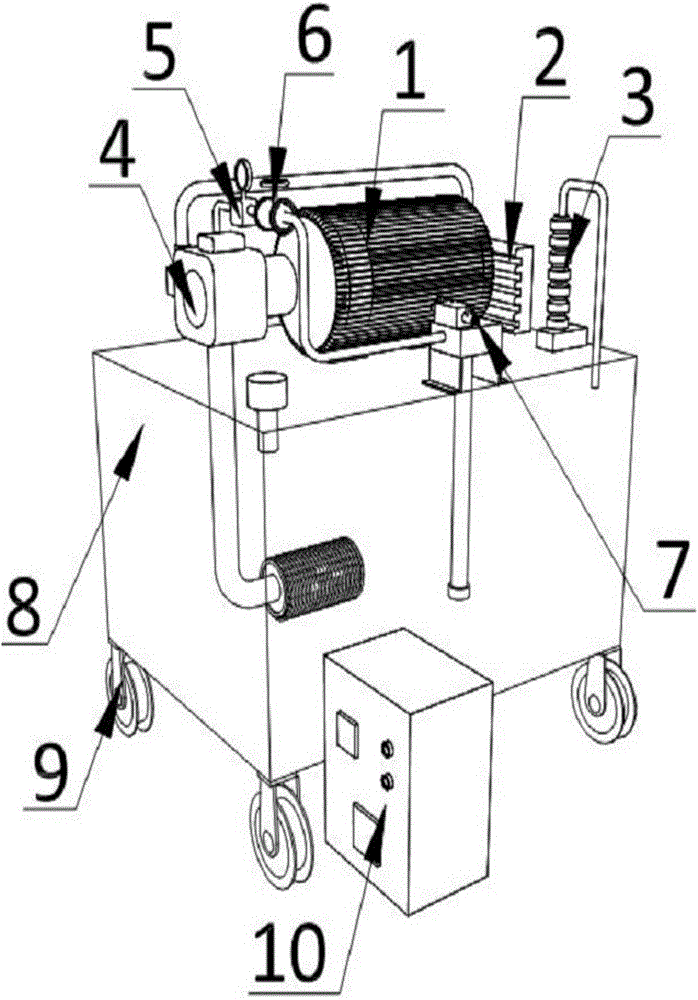

Supply hydraulic station device for carbon tetrachloride treatment and operating method thereof

A technology of carbon tetrachloride and hydraulic station, which is applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, fluid pressure actuation system safety, etc. It can solve problems such as work difficulty, wear of hydraulic components of oil pump, failure to dissipate heat, etc. , to achieve the effect of high degree of automation, simple device structure and convenient operation for employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

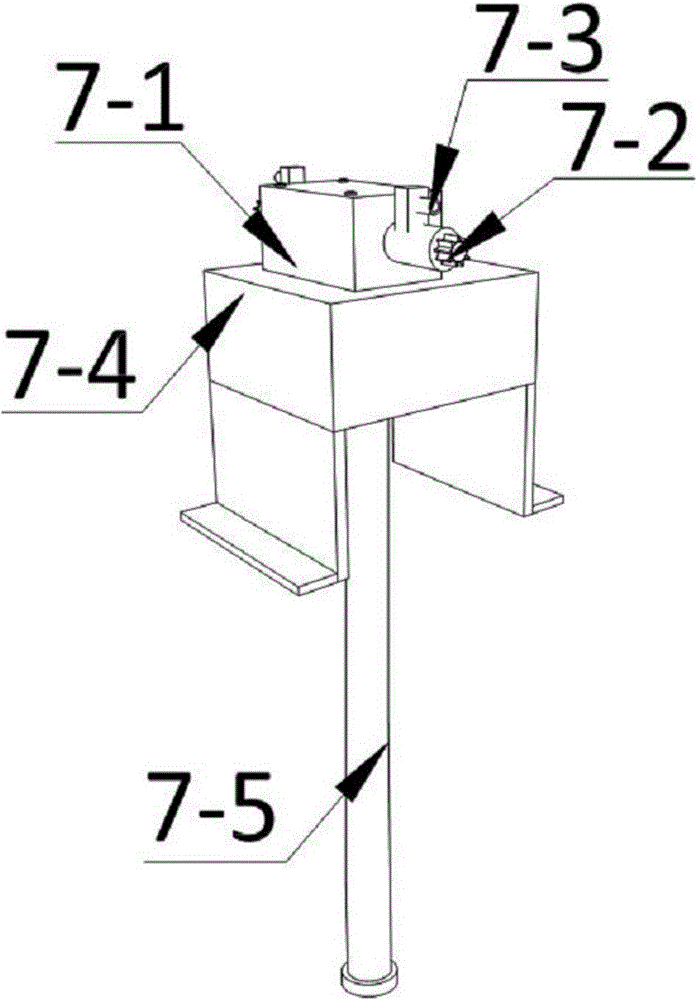

Method used

Image

Examples

Embodiment 1

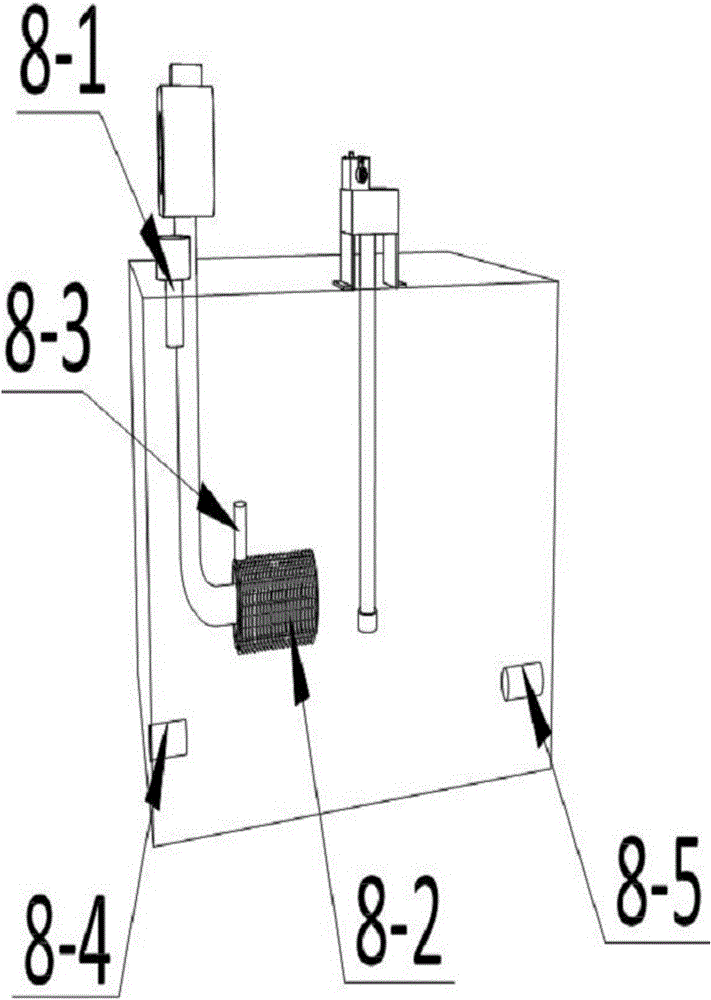

[0065] Manufacture filter screen 8-2 of the present invention according to the following steps, and in parts by weight:

[0066] Step 1: Add 1374 parts of ultrapure water with a conductivity of 2.24μS / cm into the reactor, start the stirrer in the reactor at a speed of 64rpm, start the heating pump, and increase the temperature in the reactor to 44°C; add in sequence 64 parts of methyl 2-{[(tert-butoxy)carbonyl]amino}-4-methanesulfonyl butanoate, 2-methyl-2-acrylic acid-4-[methyl(undecafluoropentyl)sulfonyl 54 parts of amino]butyl ester, 94 parts of 2-acrylic acid-2-[[(heptadecafluorooctyl)sulfonyl]methylamino]ethyl ester, stir until completely dissolved, adjust the pH value to 3.4, and turn the stirrer speed Adjust to 134rpm, the temperature is 94°C, and the esterification reaction takes 14 hours;

[0067] Step 2: Take 14 parts of polymers of 2-ethylhexyl acrylate and methyl methacrylate, 2-acrylamido-2-methylpropanesulfonic acid and methacrylic acid, 4-(4-chloro- 74 parts o...

Embodiment 2

[0072] Manufacture filter screen 8-2 of the present invention according to the following steps, and in parts by weight:

[0073] Step 1: Add 1644 parts of ultrapure water with a conductivity of 4.24μS / cm into the reactor, start the stirrer in the reactor at a speed of 124rpm, start the heating pump, and raise the temperature in the reactor to 74°C; add in order 124 parts of methyl 2-{[(tert-butoxy)carbonyl]amino}-4-methanesulfonylbutanoate, 2-methyl-2-acrylic acid-4-[methyl(undecafluoropentyl)sulfonyl Amino] butyl ester 154 parts, 2-acrylic acid-2-[[(heptadecafluorooctyl) sulfonyl] methyl amino] ethyl ester 214 parts, stir until completely dissolved, adjust the pH value to 6.4, and the stirrer speed Adjust to 254rpm, the temperature is 134°C, and the esterification reaction takes 24 hours;

[0074] Step 2: Take 54 parts of polymers of 2-ethylhexyl acrylate and methyl methacrylate, 2-acrylamido-2-methylpropanesulfonic acid and methacrylic acid, 4-(4-chloro- 134 parts of 5,6-d...

Embodiment 3

[0079] Manufacture filter screen 8-2 of the present invention according to the following steps, and in parts by weight:

[0080] Step 1: Add 1444 parts of ultra-pure water with a conductivity of 3.24μS / cm into the reactor, start the stirrer in the reactor at a speed of 94rpm, start the heating pump, and raise the temperature in the reactor to 64°C; add in sequence 84 parts of methyl 2-{[(tert-butoxy)carbonyl]amino}-4-methanesulfonyl butanoate, 2-methyl-2-acrylic acid-4-[methyl(undecafluoropentyl)sulfonyl Amino] butyl ester 134 parts, 2-acrylic acid-2-[[(heptadecafluorooctyl) sulfonyl] methyl amino] ethyl ester 184 parts, stir until completely dissolved, adjust the pH value to 4.4, turn the stirrer speed Adjust to 194rpm, the temperature is 114°C, and the esterification reaction takes 19 hours;

[0081] Step 2: Take 34 parts of polymers of 2-ethylhexyl acrylate and methyl methacrylate, 2-acrylamido-2-methylpropanesulfonic acid and methacrylic acid, 4-(4-chloro- 84 parts of 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com