Large-span underground space structure and construction method thereof

A technology with spatial structure and large span, applied in underground chambers, earthwork drilling, mining equipment, etc., can solve problems such as difficulty in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

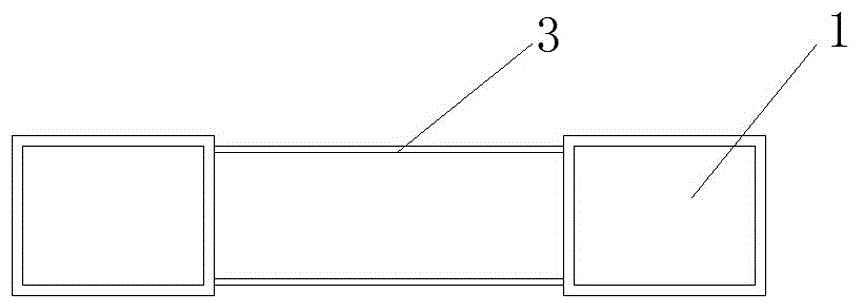

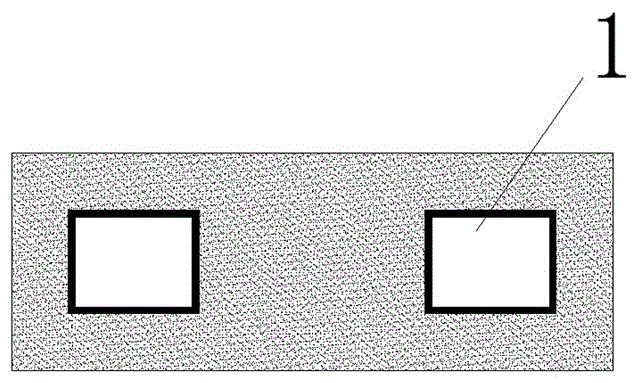

[0046] Embodiment 1: The following is a detailed description of the combined construction method of the large-span underground space structure of the structure; Figure 3~6 Shown:

[0047] Step 1: Longitudinal tunnel mechanized construction; use shield machine and pipe jacking machine to construct two parallel tunnels; advance tunnel as the longitudinal load-bearing structure of space structural unit, its cross-sectional shape can be rectangular or similar rectangular tunnel, circular tunnel Or horseshoe tunnel.

[0048] Step 2: Transverse tube curtain mechanization construction; use tube curtain machine for tube curtain construction to form a span-direction structure; tube curtain machine starts from one tunnel and receives from the other tunnel. After the tube curtain is formed, it is the tube curtain of the two tunnels. Pouring supports at the ends to fix both ends of the tube curtain; where the structure is located in a layer with a lot of water, a tube curtain structure with a...

Embodiment 2

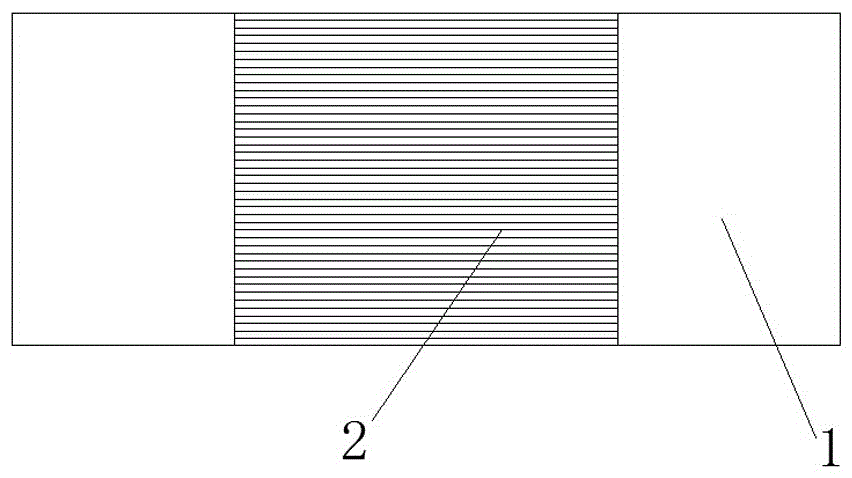

[0052] Embodiment 2: The following is a detailed description of the construction method of the depth direction combination of the large-span underground space structure set up in the structure; Figure 7~10 Shown:

[0053] Step 1: Longitudinal tunnel mechanized construction; use shield machine and pipe jacking machine to construct two parallel tunnels; advance tunnel as the longitudinal load-bearing structure of space structural unit, its cross-sectional shape can be rectangular or similar rectangular tunnel, circular tunnel Or horseshoe tunnel.

[0054] Step 2: Transverse tube curtain mechanization construction; use tube curtain machine for tube curtain construction to form a span-direction structure; tube curtain machine starts from one tunnel and receives from the other tunnel. After the tube curtain is formed, it is the tube curtain of the two tunnels. Pouring supports at the ends to fix both ends of the tube curtain; where the structure is located in a layer with a lot of wate...

Embodiment 3

[0058] Embodiment 3: The following is a detailed description of the construction method of the arch structure tube-curtain combination of the large-span underground space structure set up in the structure; Figure 11-14 Shown:

[0059] Step 1: Longitudinal tunnel mechanized construction; use shield machine and pipe jacking machine to construct two parallel tunnels; advance tunnel as the longitudinal load-bearing structure of space structural unit, its cross-sectional shape can be rectangular or similar rectangular tunnel, circular tunnel Or horseshoe tunnel.

[0060] Step 2: The mechanized construction of the horizontal curved tube curtain; the curved tube curtain machine is used to construct the tube curtain to form a structure in the span direction; the tube curtain machine starts from one tunnel and receives from the other tunnel. After the tube curtain is formed, it is in the two tunnels. Pouring supports at the ends of the tube screen to fix both ends of the tube screen; wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com