A kind of hole sealing device for coal mine

A technology of hole sealer and coal mine, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and mining, etc. It can solve the problems of drilling failure, air leakage, large cracks on the upper wall of the drilling hole, etc., and reduce labor Strength, simple and reliable operation, good plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

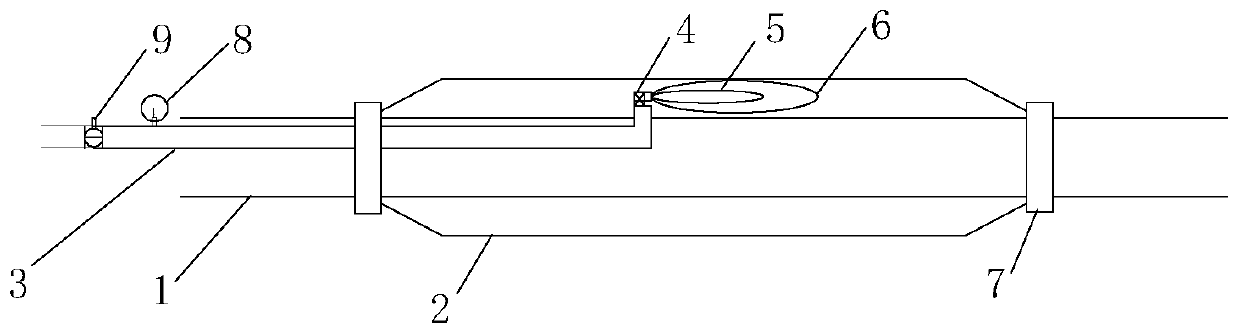

[0017] A hole sealing device for coal mines, which is installed on the extraction pipe, the sealing device includes a water injection pipe arranged in the inner cavity of the extraction pipe and pierced through the wall of the pipe to form an opening, a pressure pipe wrapping the extraction pipe and covering the opening, and On both sides of the opening, the pressure-bearing pipe is sealed and fixed to the two steel hoops of the extraction pipe; the pressure-bearing pipe is respectively a rubber layer, a woven cloth layer, and a flame-retardant and antistatic protective layer from the inside to the outside. The protective layer is a combination of flame retardant rubber and antistatic rubber.

[0018] The fabric layer is made of any one of nylon, polyester, and aramid, or any two or three blends of nylon, polyester, and aramid. The woven layer is used to control the expansion volume of the pressure tube to prevent excessive expansion and rupture.

[0019] An expansion bag com...

Embodiment 2

[0022] Such as figure 1 As shown, a hole sealing device for coal mine is installed on the extraction pipe 1. The hole sealing device includes a water injection pipe 3 arranged in the inner cavity of the extraction pipe 1 and pierced through the pipe wall to form an opening, wrapping the extraction pipe 1 and The pressure-bearing pipe 2 covering the opening, and the two steel hoops 7 that seal and fix the pressure-bearing pipe 2 to the extraction pipe 1 on both sides of the opening; Flame retardant and antistatic treated protective layer, the protective layer is composed of flame retardant rubber and antistatic rubber. The fabric layer is made of nylon material.

[0023] Between the pressure-bearing pipe 2 and the water injection pipe 3, there is also an expansion bag communicated with the opening of the water injection pipe 3, and the expansion bag is spherical or ring-shaped when it is filled. This embodiment is spherical, and the spherical expansion bladder can expand and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com