Preparation method of delta-ferrite-containing TRIP (transformation induced plasticity) steel

A technology of ferrite and preparation steps, applied in the field of high-strength steel for automobiles, can solve the problems of loss of optimal strength-plastic balance, poor weldability, surface oxidation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The mass percentage of the chemical composition of the slab is C: 0.25%, Si: 0.62%, Mn: 2.2%, Alt: 3.15%, P: 0.006%, S+N: 0.007%, and the rest is Fe and unavoidable impurities.

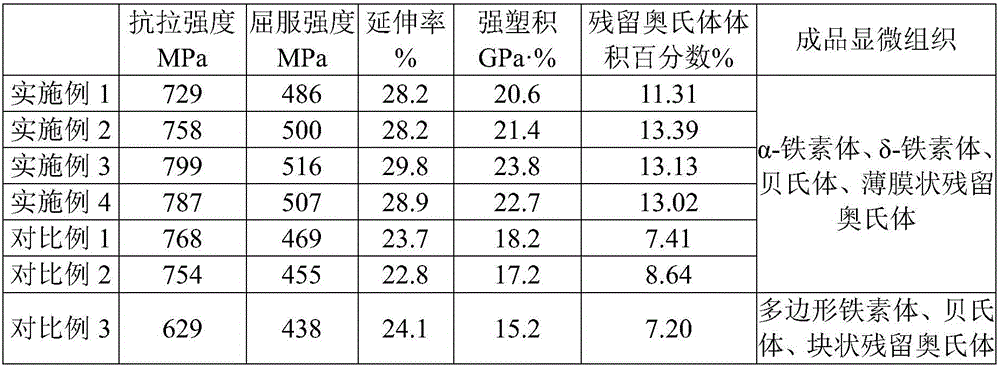

[0023] Heat the cast slab at 1150°C, keep it warm for 1 hour, then carry out 2 passes of rough rolling; after rough rolling, it enters the coil box for induction heating, the induction heating temperature is 1050°C, and the holding time is 10 minutes; Steel edge heating device, the finish rolling temperature is 950°C; after finish rolling, it enters ultra-fast cooling, the cooling speed is 220°C / s, the steel strip is cooled to 280°C and then coiled to obtain a hot-rolled steel strip with a thickness of 2.5mm steel belt. Then the hot-rolled steel strip is heat-treated, heated to 800°C for 2 minutes, then rapidly cooled to 400°C, coiled, then put into the heat preservation pit and slowly cooled to 200°C, taken out and naturally cooled to room temperature. The key process parameters are shown in ...

Embodiment 2

[0025] The mass percentage of the chemical composition of the slab is C: 0.26%, Si: 0.81%, Mn: 2.4%, Alt: 2.97%, P: 0.007%, S+N: 0.005%, and the rest is Fe and unavoidable impurities. Take the same preparation steps as in Example 1, the process parameters are as shown in Table 1, and the process parameters not listed in Table 1 are the same as in Example 1. The mechanical properties and structure of the finished product are shown in Table 2.

Embodiment 3

[0027] The chemical composition of the slab is the same as in Example 1. Take the same preparation steps as in Example 1, the process parameters are as shown in Table 1, and the process parameters not listed in Table 1 are the same as in Example 1. The mechanical properties and structure of the finished product are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com