Producing and processing technology of superplastic pure iron material

A processing technology and superplastic technology, which is applied in the production and processing technology field of superplastic pure iron materials, can solve problems such as poor processing performance, and achieve the effects of high plasticity, considerable economic benefits, and good market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

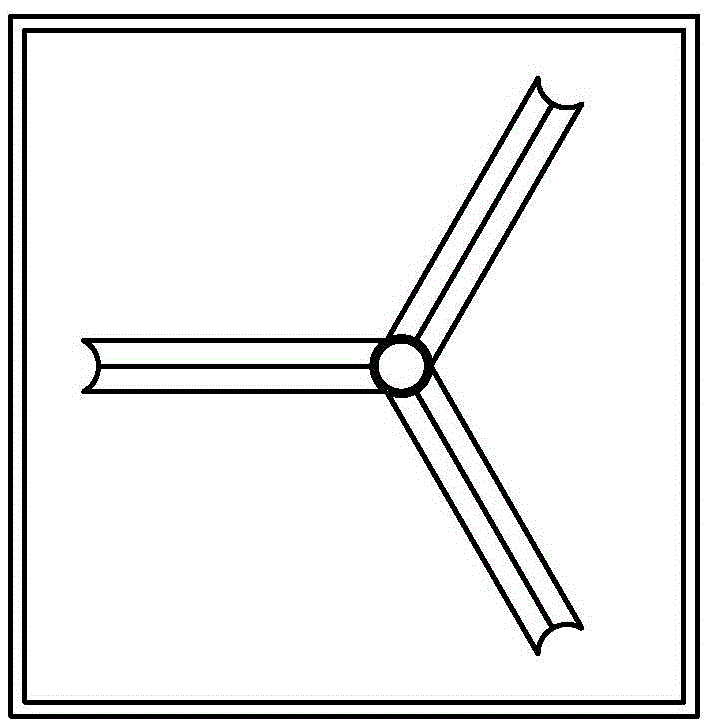

Image

Examples

Embodiment 1

[0025] (1) Material selection: The domestically produced model CH1T material is selected as the base material, the content of the alloy element Ti is controlled at 0.06%, the content of S and P is both 0.019%, and there is no non-metallic inclusions inside;

[0026] (2) Drawing: use roller die drawing technology to draw the material to obtain steel wire;

[0027] (3) Annealing: Using the isothermal recrystallization annealing process, place the steel wire in a heat treatment furnace, fill the heat treatment furnace with inert gas, then raise the temperature in the furnace to 680°C and keep it for 1.5h; then, heat it at 18°C Cool down to 580°C at a cooling rate of / h, and keep the temperature for 2h, and then return to normal temperature at a cooling rate of 40°C / h. The inert gas is methanol, and the flow rate of methanol gas is 2L / min.

Embodiment 2

[0029] (1) Material selection: The domestically produced CH1T material is selected as the base material, the alloy element Ti content is controlled at 0.12%, the S and P content are both below 0.018%, and there are no non-metallic inclusions inside;

[0030] (2) Drawing: use roller die drawing technology to draw the material to obtain steel wire;

[0031] (3) Annealing: Using the isothermal recrystallization annealing process, place the steel wire in a heat treatment furnace, fill the heat treatment furnace with inert gas, then raise the temperature in the furnace to 670 ° C, and keep it for 1 hour; then, at 15 ° C / Cool down to 600°C at a cooling rate of h, and keep the temperature for 2.5h, and then return to room temperature at a cooling rate of 50°C / h. The inert gas is methanol, and the flow rate of methanol gas is 2L / min.

Embodiment 3

[0033] (1) Material selection: The domestically produced CH1T material is selected as the base material, the alloy element Ti content is controlled at 0.10%, the S and P content are both 0.015%, and there are no non-metallic inclusions inside;

[0034] (2) Drawing: use roller die drawing technology to draw the material to obtain steel wire;

[0035] (3) Annealing: Using the isothermal recrystallization annealing process, place the steel wire in a heat treatment furnace, fill the heat treatment furnace with inert gas, then raise the temperature in the furnace to 660 ° C, and keep it for 2 hours; then, at 20 ° C / Cool down to 590°C at a cooling rate of h, and keep the temperature for 3h, and then return to room temperature at a cooling rate of 30°C / h. The inert gas is methanol, and the flow rate of methanol gas is 2L / min.

[0036] The products obtained after the treatment of the above-mentioned embodiments are inspected for spheroidization level, grain size, depth of decarburi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com