Carbothermy-based hot metal pretreatment in-situ desulphurization method for magnesite-based desulfurizers

A technology of molten iron pretreatment and desulfurization agent, which is applied in the field of molten iron pretreatment, can solve the problems of high energy consumption and environmental pollution, and achieve the effects of simplified desulfurization process, wide resources and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

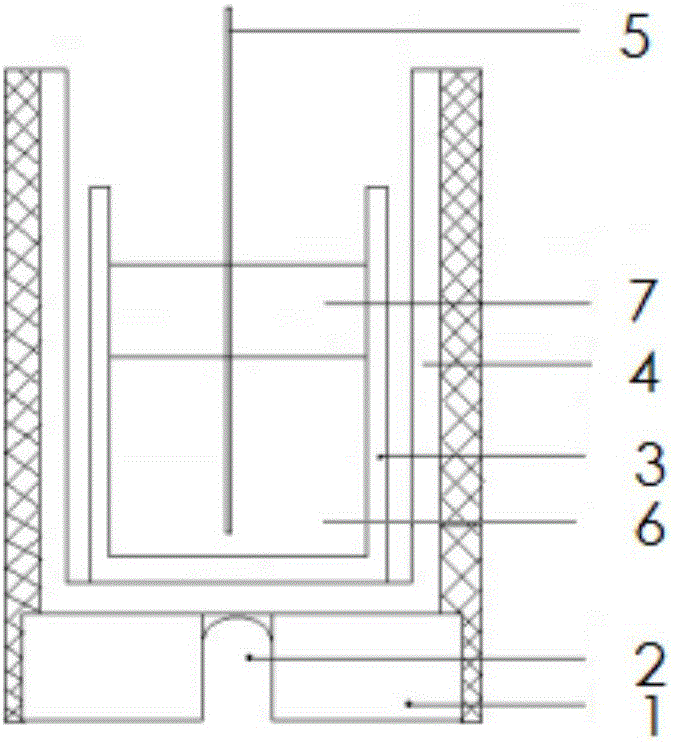

Image

Examples

Embodiment

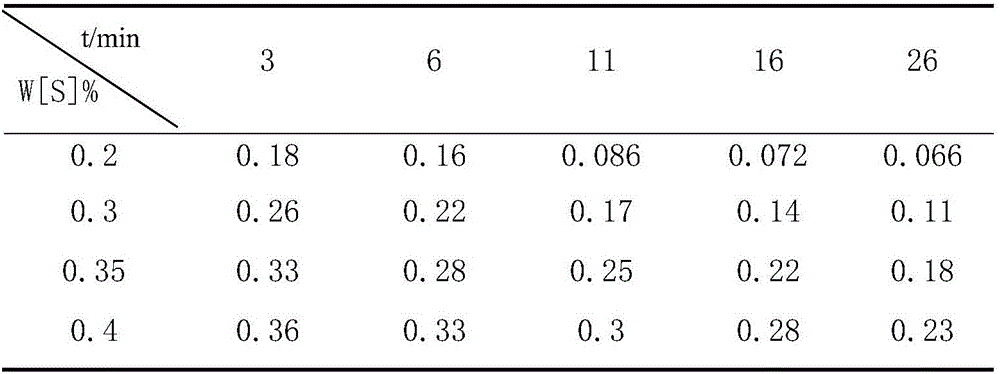

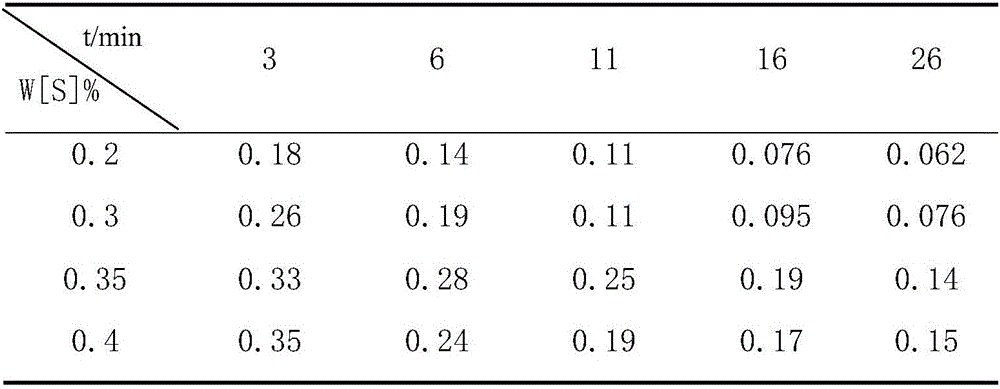

[0023] The carbothermal magnesite-based desulfurizer molten iron pretreatment in-situ desulfurization method is completed according to the following steps:

[0024] a. The molten iron raw material used is blast furnace pig iron, and the sulfur content is adjusted with ferrous sulfide. Weigh 200g of pig iron with initial sulfur content of 0.2%, 0.3%, 0.35%, and 0.4%, respectively, and put them into a 300°C electric blast drying oven Dry at constant temperature for 2 hours;

[0025] b. Prepare magnesite-based desulfurizer according to mass percentage, and its proportion is as follows: MgO 38%, graphite powder 11%, Al12%, Fe 2 o 3 33%, SiO 2 +CaO 5.3%, CaF 2 0.7%, grind the components separately, mix them and put them in a 300°C electric blast drying oven for 2 hours to dry at a constant temperature; wrap 20g of the prepared desulfurizer with rice paper and set aside;

[0026] c. Turn on the high temperature resistance furnace program control device, set parameters: heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com