A kind of preparation method of emulsified heavy oil

A heavy oil and emulsifier technology, applied in the petroleum industry, processing hydrocarbon oil, refining by dialysis, etc., can solve the problems of complex process, difficult to meet the water-in-oil emulsion, etc., to improve the jet flow, reduce the surface energy and Oil-water interfacial tension and emulsification effect are obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

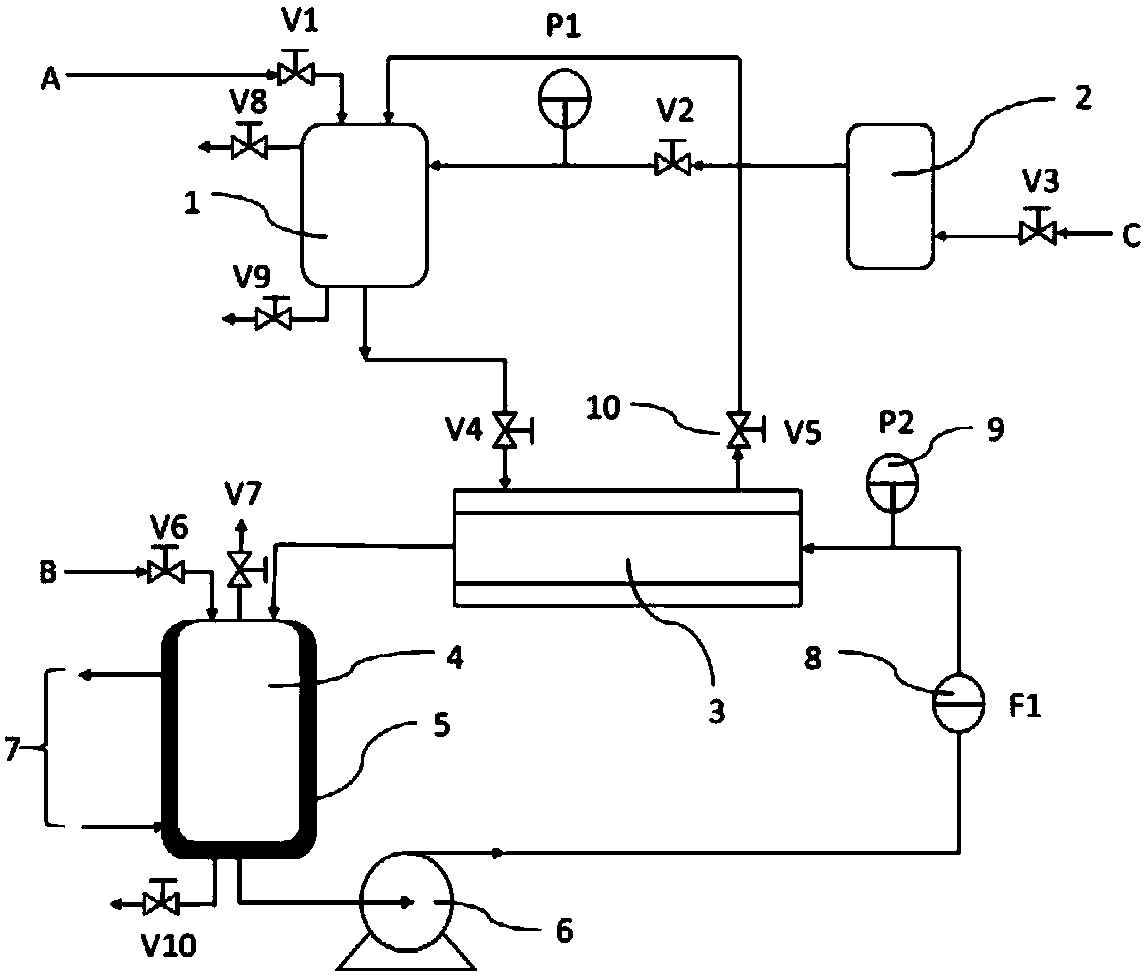

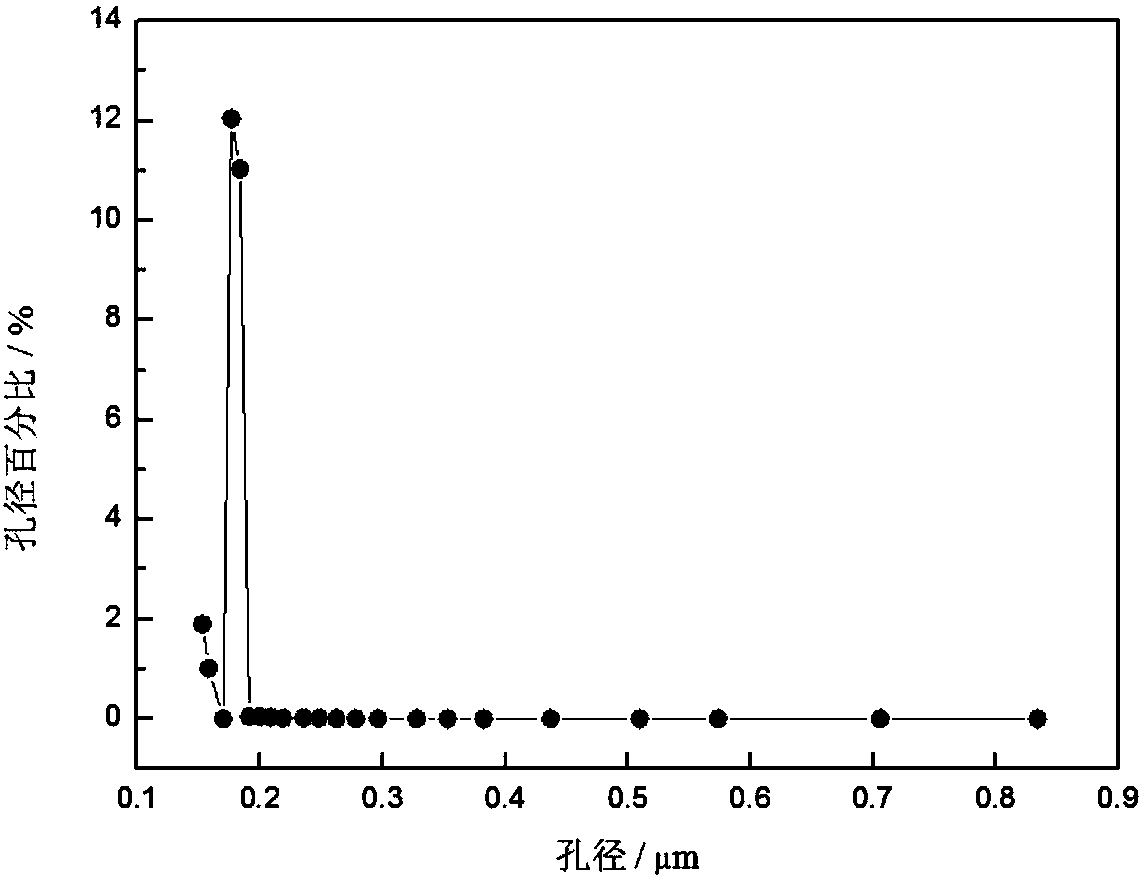

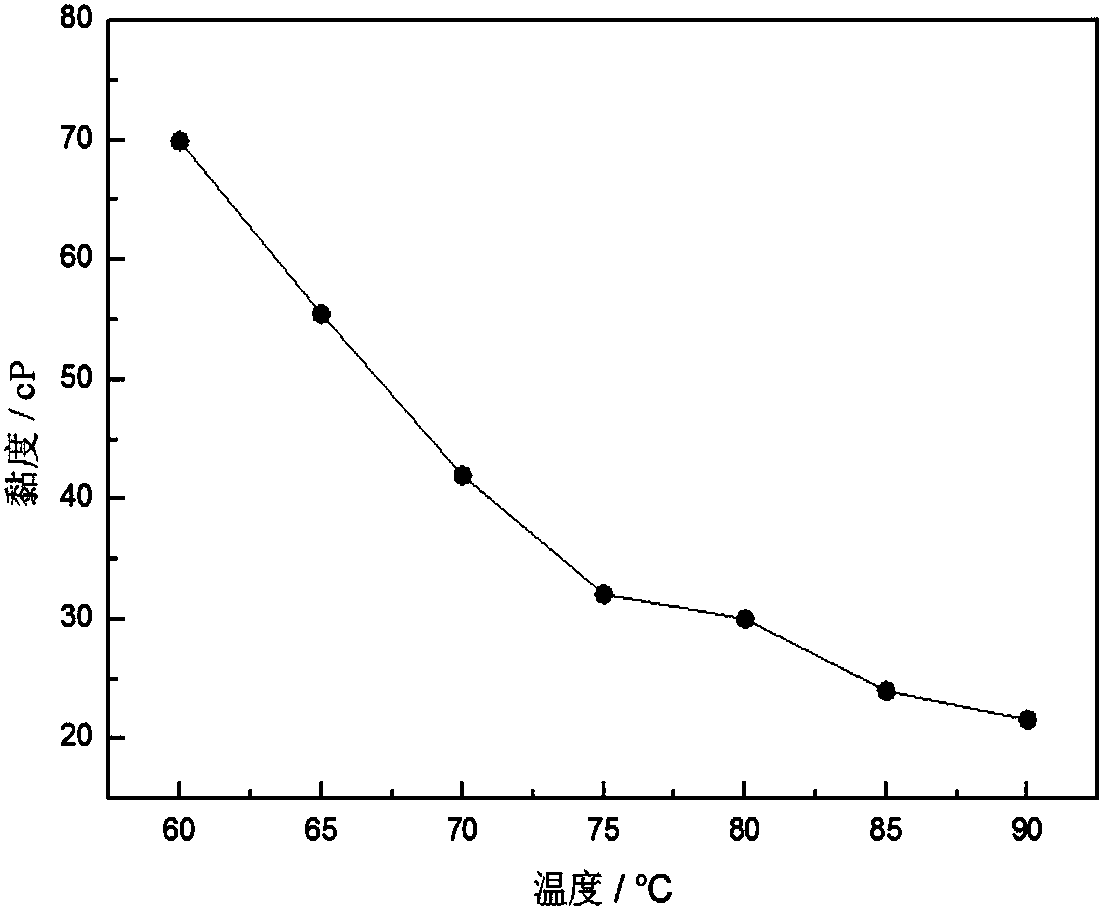

[0025] Single-channel tubular Al with a nominal pore size of 200nm 2 o 3 The ceramic membrane is a jet membrane emulsification medium, and its pore size distribution is as follows: figure 2 As shown, the pore size distribution is relatively concentrated, the most probable pore size is 180nm, and the maximum pore size is 1.15μm. The ceramic membrane was first soaked in the dispersed phase for 12h. image 3 The change relationship between the viscosity of heavy oil and temperature is the relationship between the viscosity of heavy oil and the viscosity of heavy oil decreases with the increase of temperature. In order to reduce the viscosity of heavy oil, the temperature of continuous phase is controlled at 90 °C. The circulating oil pump is used to provide the shear force on the membrane surface, and the flow velocity on the membrane surface is controlled to be 1.0m / s. The emulsifier in the dispersed phase is a mixture of Tween-20 and sodium lauryl sulfate with a mass ratio ...

Embodiment 2

[0029] Single-channel tubular Al with a nominal pore size of 200nm 2 o 3The ceramic membrane is a jet membrane emulsification medium, and it is first soaked in the dispersed phase for 12 hours. In order to reduce the viscosity of heavy oil, the continuous phase temperature was kept at 90 °C. The circulating oil pump is used to provide the shear force on the membrane surface, and the flow velocity on the membrane surface is controlled to be 1.0m / s. The emulsifier is a mixture of Tween-20 and sodium lauryl sulfate at a mass ratio of 1:1, the volume content of the emulsifier in the dispersed phase is 200ppm, and the continuous phase is heavy oil. Under the pressure of 0.12MPa, the flux of the dispersed phase through the membrane pores is 42.46L m -2 h -1 . Control the water content (volume) in the emulsified heavy oil to be 8%. The particle size range of the prepared emulsion is 1-15 μm.

Embodiment 3

[0033] Single-channel tubular ZrO with a nominal pore size of 100nm 2 The ceramic membrane is a jet membrane emulsification medium, and it is first soaked in the dispersed phase for 12 hours. In order to reduce the viscosity of heavy oil, the continuous phase temperature was kept at 90 °C. The circulating oil pump is used to provide the shear force on the membrane surface, and the flow velocity on the membrane surface is controlled to be 1.0m / s. The emulsifier is a mixture of Tween-20 and Span-60 with a mass ratio of 1:1, the volume content of the emulsifier in the dispersed phase is 400ppm, and the continuous phase is heavy oil. Under the pressure of 0.15MPa, the flux of the dispersed phase through the membrane pores is 88.25L m -2 h -1 . Control the water content (volume) in the emulsified heavy oil to be 8%. The particle size range of the prepared emulsion is 1-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com