Extra weather-resistant micro-spherical powder coating used for metal coiled material and prepared through supercritical fluid technology and preparation method thereof

A supercritical fluid, metal coil technology, used in powder coatings, polyester coatings, coatings, etc., can solve the problems of difficulty in meeting its requirements, and achieve improved flatness, good weather resistance, and high particle size distribution concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

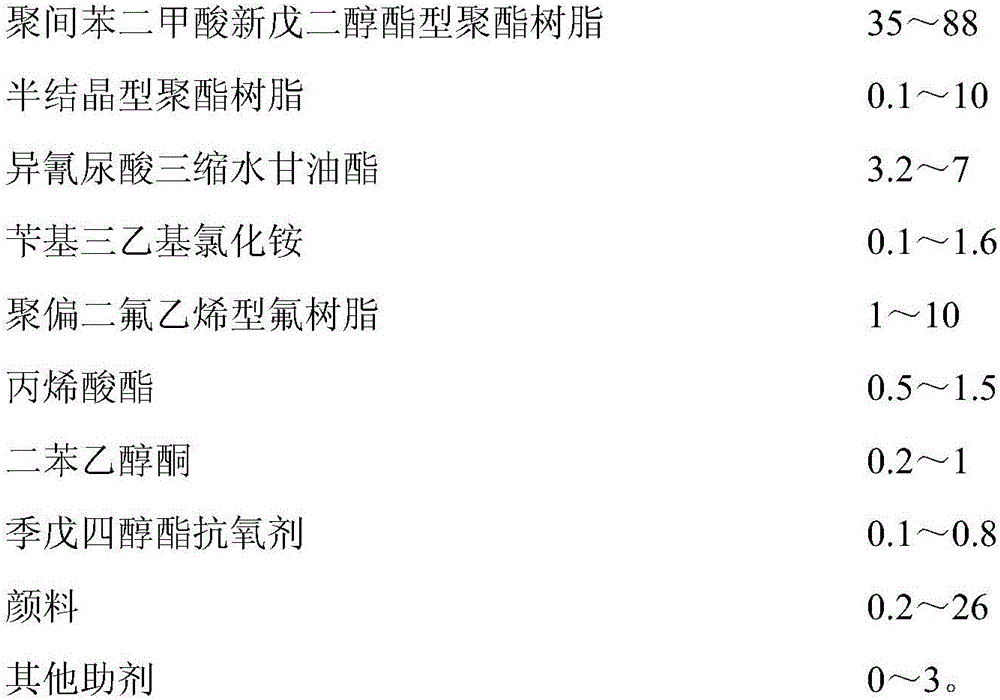

[0035] The super-weather-resistant microspherical powder coating for metal coils prepared by the supercritical fluid technology of this embodiment is made of the raw materials in the following mass percentages:

[0036]

[0037] The triglycidyl isocyanurate curing agent described in the raw material formula requires its total chlorine (organic chlorine and inorganic chlorine) content to be less than or equal to 0.4%.

[0038] Put the raw materials into the supercritical reactor and mix them evenly, and control the CO in the reactor 2 The content is 55wt%, the temperature is 55°C, and the pressure is 90Kg / cm 2 , the outlet temperature was 70°C. A super weather-resistant microspherical powder coating for metal coils with a particle size D50 of 18 μm was prepared.

[0039] The specific performance of the product of this embodiment is shown in Table 1.

Embodiment 2

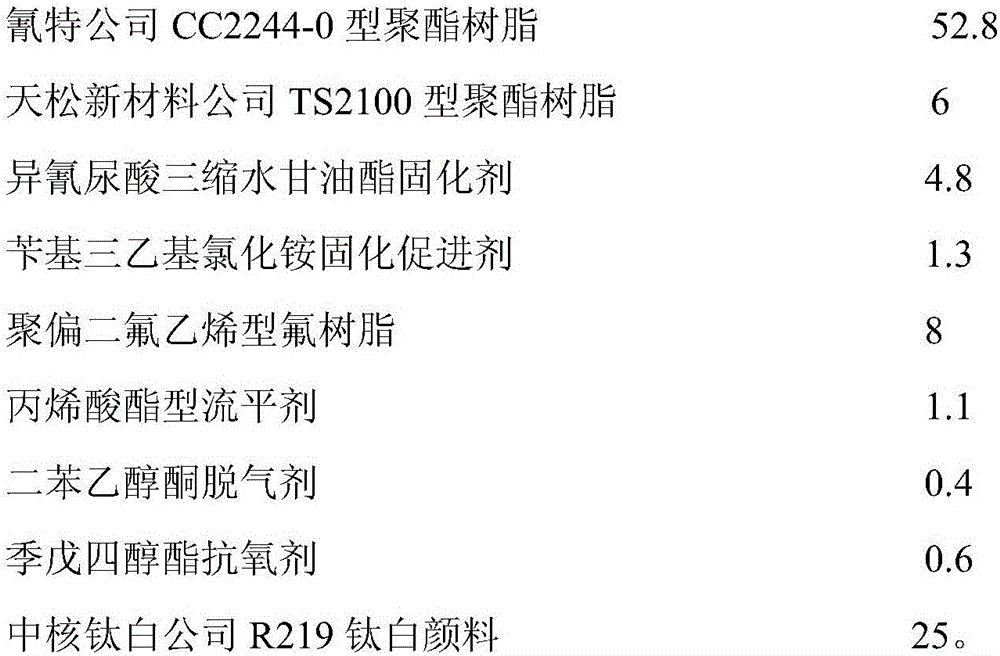

[0041] The super-weather-resistant microspherical powder coating for metal coils prepared by the supercritical fluid technology of this embodiment is made of the raw materials in the following mass percentages:

[0042]

[0043] The triglycidyl isocyanurate curing agent described in the raw material formula requires its total chlorine (organic chlorine and inorganic chlorine) content to be less than or equal to 0.4%.

[0044] Put the raw materials into the supercritical reactor and mix them evenly, and control the CO in the reactor 2 The content is 35wt%, the temperature is 48°C, and the pressure is 110Kg / cm 2 , the outlet temperature was 56°C. A super weather-resistant microspherical powder coating for metal coils with a particle size D50 of 22 μm was prepared.

[0045] The specific performance of the product of this embodiment is shown in Table 1.

Embodiment 3

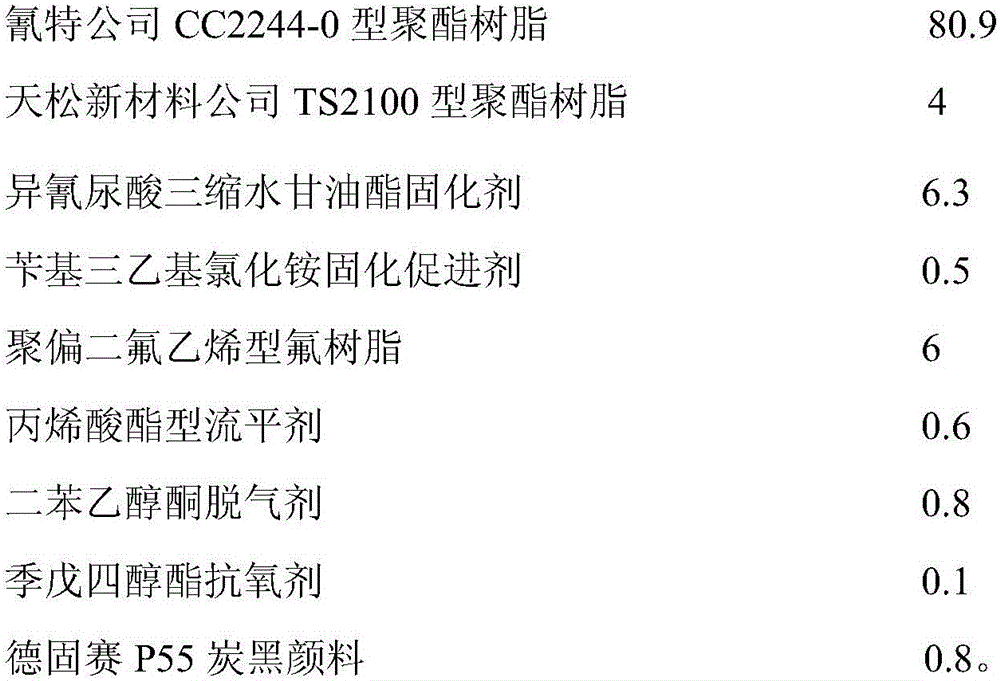

[0047] The super-weather-resistant microspherical powder coating for metal coils prepared by the supercritical fluid technology of this embodiment is made of the raw materials in the following mass percentages:

[0048]

[0049] The triglycidyl isocyanurate curing agent described in the raw material formula requires its total chlorine (organic chlorine and inorganic chlorine) content to be less than or equal to 0.4%.

[0050] Put the raw materials into the supercritical reactor and mix them evenly, and control the CO in the reactor 2 The content is 42wt%, the temperature is 68°C, and the pressure is 70Kg / cm 2 , the outlet temperature was 64°C. A super weather-resistant microspherical powder coating for metal coils with a particle size D50 of 14 μm was prepared.

[0051] The specific performance of the product of this embodiment is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com