Capsanthin solvent extracting solution evaporation method and device

A technology for evaporation equipment and extraction liquid, which is applied to evaporation, separation methods, chemical instruments and methods, etc., can solve the problems of unpleasant capsicum red extraction liquid concentration, small processing capacity, and large loss of color value, and achieves easy continuous industrial production. , The effect of low evaporation temperature and less loss of color value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

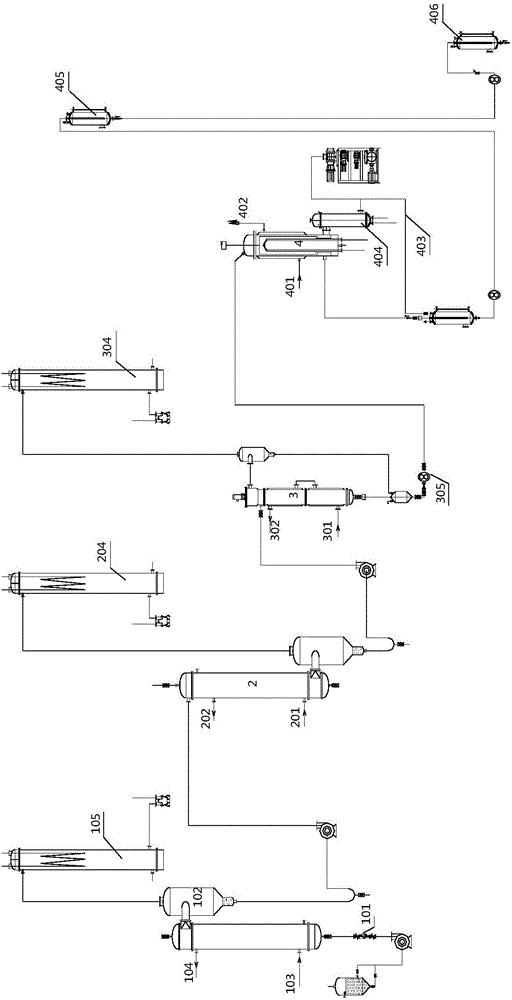

[0040] Capsanthin solvent extract evaporation equipment includes sequentially connected rising film evaporators, falling film evaporators, and rotary thin film evaporators.

[0041] Capsicum granule is extracted with the normal hexane and acetone mixed solvent of volume ratio 8:2, by the solid-liquid ratio of 1kg:3L and obtains capsanthin solvent extract,

[0042] 1) The capsanthin solvent extract with a color value of 7.85 is 11 ± 0.2m 3 The / h flow rate is measured by the rotameter flow rate 101, and the centrifugal pump is pumped into the 150㎡ rising film evaporator tube side to exchange heat with the hot water at 65±1℃ in the rising film shell side, and the pressure in the rising film tube side is controlled at -0.05±0.005MPa, the gas phase outlet temperature of the rising film evaporation is controlled at 54±1°C, the extraction liquid enters the flash tank through the gas balance pipe on the upper part of the rising film, evaporates in the flash tank, and the solvent vapo...

Embodiment 2

[0049] see figure 1 , Capsanthin solvent extract evaporation equipment, comprising a rising film evaporator 1, a falling film evaporator 2, a rotary thin film evaporator 3 and a molecular distillation evaporator 4 connected in sequence,

[0050] The upper part of the rising film evaporator 1 is connected with a rising film evaporation flash box 102 through a gas balance pipe, and a liquid outlet is arranged at the bottom of the rising film evaporation flash box 102;

[0051] The upper part of the falling film evaporator 2 is connected with a falling film evaporation flash box through a gas balance pipe 203, and a liquid outlet is arranged at the bottom of the falling film evaporation flash box;

[0052] The upper part of the rotary film evaporator 3 is connected to a rotary film evaporation flash box through a gas balance pipe, and a liquid outlet is arranged at the bottom of the rotary film evaporation flash box;

[0053] The discharge pipeline of the rotary thin film evapor...

Embodiment 3

[0059] Adopt the equipment of embodiment 2. Capsicum granules are extracted with a mixed solvent of n-hexane and acetone at a volume ratio of 8:2 to obtain capsanthin solvent extract by a solid-liquid ratio of 1:3.

[0060] 1) The capsanthin solvent extract with a color value of 7.85 is 11 ± 0.2m 3 / h flow rate, measured by the rotameter flow rate, pumped into the 150㎡ rising film evaporator tube side by the centrifugal pump, and heat exchange with the hot water at 65±1℃ in the rising film shell side, the pressure in the rising film tube side is controlled at -0.05±0.005MPa, the gas phase outlet temperature of the rising film evaporation is controlled at 54±1°C, the extraction liquid enters the flash tank through the gas balance pipe on the upper part of the rising film, evaporates in the flash tank, and the solvent vapor is condensed and recovered through the pipeline for recycling , the red capsicum is discharged to the liquid receiving tank through the discharge pipe at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com