Sheath material, cold-resistant power cable and production method thereof

A production method and power cable technology, applied in power cables, insulated cables, cable/conductor manufacturing, etc., can solve the problems of sheath cracking, affecting the normal laying and safe operation of cable lines, insulation breakdown, etc., and achieve extreme cold resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

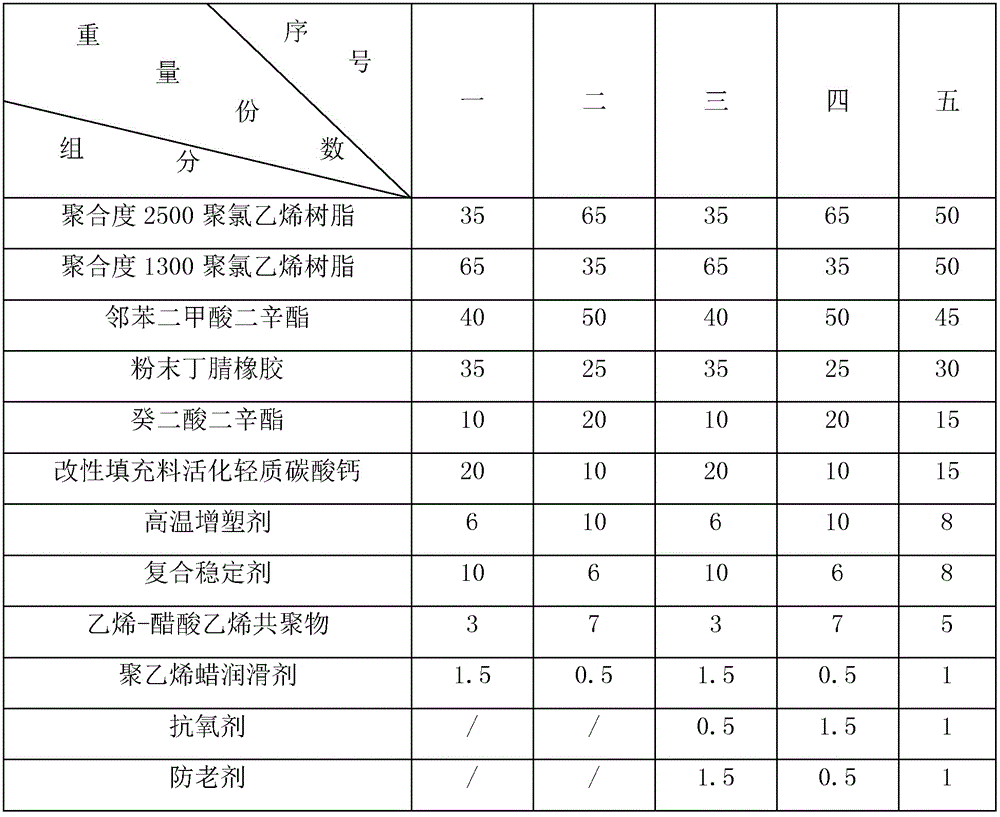

[0028] A kind of sheathing material, the consumption of each component of its raw material is figure 1 As shown in No. 1, preferably, the powdered nitrile rubber is P83 powdered nitrile rubber, and the composite stabilizer is a Ca-Zn composite stabilizer.

[0029] Its production method is:

[0030] Weigh each component of the raw material of the sheath material in proportion, send each component except powdered nitrile rubber into a high-speed mixer and stir at a speed of 450r / min for 5 minutes, then stir at a speed of 900r / min until the temperature rises To 100°C, add nitrile rubber powder and stir for 1.5 minutes, discharge the material into a cooling mixer at a speed of 100r / min, stir and cool for 5 minutes, then discharge and granulate to obtain a sheath material. The high-speed mixer described in this embodiment is selected from SHR-500A high-speed mixer, and other types of high-speed mixers can also be used. The cooling mixer described in this embodiment is selected fro...

Embodiment 2

[0032] A kind of sheathing material, the consumption of each component of its raw material is figure 1 As shown in No. 2, preferably, the powdered nitrile rubber is P83 powdered nitrile rubber, and the composite stabilizer is a Ca-Zn composite stabilizer.

[0033] Its production method is basically the same as Example 1, except that each component except powdered nitrile rubber is sent into a high-speed mixer and stirred at a speed of 550r / min for 3 minutes, then stirred at a speed of 700r / min to the temperature Raise to 120°C, add nitrile rubber powder and stir for 0.5 minutes, discharge the material into a cooling mixer and stir and cool at a speed of 100r / min for 3 minutes.

Embodiment 3

[0035] A kind of sheathing material, the consumption of each component of its raw material is figure 1 As shown in the serial number three, preferably, the powdered nitrile rubber is P83 powdered nitrile rubber, the composite stabilizer is a Ca-Zn composite stabilizer, the antioxidant is a bisphenol A antioxidant, the Anti-aging agent is anti-aging agent 4010.

[0036] Its production method is basically the same as Example 1, wherein the difference is: send each component except powdered nitrile rubber into a high-speed mixer and stir for 4 minutes with a rotating speed of 500r / min, then stir to a temperature of 800r / min with a rotating speed Raise to 110°C, add nitrile rubber powder and stir for 1 minute, discharge the material into a cooling mixer and stir and cool at a speed of 100r / min for 4 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com