Method for performing catalyzed synthesis on polyaspartic acid through one-step process of novel solid acid catalyst

A solid acid catalyst, a technology of polyaspartic acid, which is applied in the field of one-step catalytic synthesis of polyaspartic acid with a novel solid acid catalyst, can solve the problems of tediousness, unsuitability for large-scale production, and low molecular weight of polyaspartic acid. , to achieve the effect of improving molecular mass, environmental protection and pollution-free catalytic performance, and simple post-treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

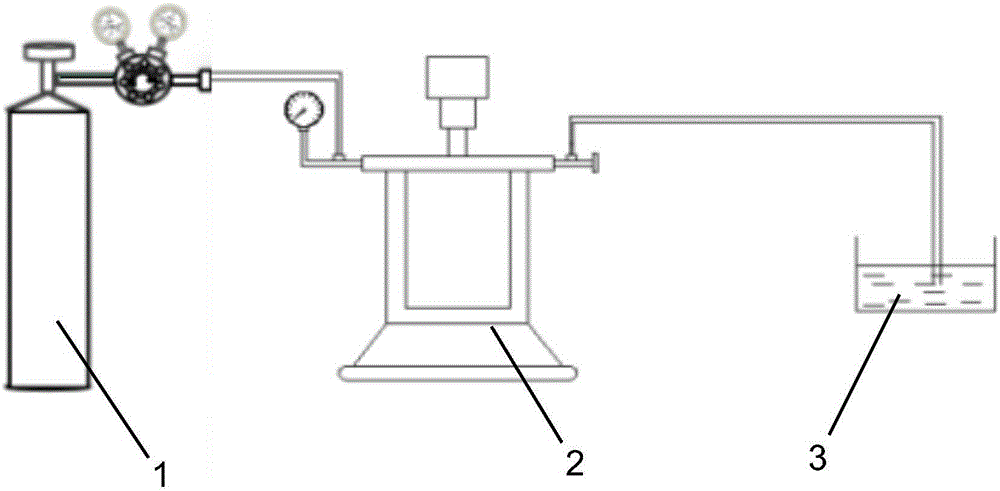

[0035] Accurately take by weighing 98g maleic anhydride and put into the reactor, add 5mL deionized water in the reactor, pass into cooling water, then drip ammoniacal liquor with the speed of 5mL / min in the described reactor, the added The molar ratio of ammonia water and maleic anhydride is 1.3:1, raise the temperature to 80°C, react for 2h, after the reaction finishes, open the outlet valve, drain the water, then add 9.8g of acid-modified montmorillonite in the reaction kettle Remove the soil (modified by 85% phosphoric acid) and 25mL of liquid paraffin, cover the lid of the reaction kettle, tighten the screws, and then continue to increase the temperature to 200 ° C, feed nitrogen to increase the pressure to 5 MPa, react for 2 hours, and pass through cooling Cool with water, when it cools down to 50°C, open the reaction kettle, release the reaction liquid from the bottom while it is hot, pour out the liquid paraffin in the reaction liquid and recover it, and put the reddish...

Embodiment 2

[0037] Accurately weigh 98g maleic anhydride and put it into the reactor, add 15mL of deionized water into the reactor, pass into cooling water, then slowly add ammoniacal liquor dropwise in the reactor, the added ammoniacal liquor and maleic butene The mol ratio of diacid anhydride is 1.3:1, raises temperature to 60 ℃, reacts 3h, after reaction finishes, open outlet valve, discharge moisture, then add the acid-modified montmorillonite (sulfuric acid) of 19.6g in described reactor Modified) and 100mL of liquid paraffin, cover the lid of the reaction kettle, tighten the screws, then continue to raise the temperature to 160°C, feed nitrogen to increase the pressure to 6MPa, react for 4 hours, feed cooling water to cool, and wait to cool to At 40°C, open the reaction kettle, release the reaction liquid from the bottom while it is hot, pour out and recover the liquid paraffin in the reaction liquid, and place the reddish-brown viscous liquid in the reactor, add 20mL deionized water...

Embodiment 3

[0039]Accurately weigh 98g maleic anhydride and put it into the reactor, add 10mL deionized water into the reactor, pass into cooling water, then drip ammoniacal liquor at a rate of 4mL / min in the reactor, the added The molar ratio of ammonia water and maleic anhydride is 1.5:1, raise the temperature to 70°C, react for 2h, after the reaction finishes, open the outlet valve, drain the water, then add 19.6g of acid-modified Mongolian in the reaction kettle Remove soil (modified by hydrochloric acid) and 60mL of liquid paraffin, cover the lid of the reaction kettle, tighten the screws, and then continue to raise the temperature to 220 ° C, feed nitrogen to increase the pressure to 4 MPa, react for 2 hours, and feed cooling water to cool , when it is cooled to 60°C, open the reaction kettle, release the reaction liquid from the bottom while it is hot, pour out the liquid paraffin in the reaction liquid and recover it, and put the reddish-brown viscous liquid in the reactor, add 20m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com