Preparation method for high-purity glycerin polyethenoxy ether ricinoleate

A technology of polyoxyethylene ether and ricinoleate, which is applied in the field of preparation of high-purity glycerol polyoxyethylene ether ricinoleate, can solve problems such as poor effect, achieve high stability, light color, and easy product quality The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

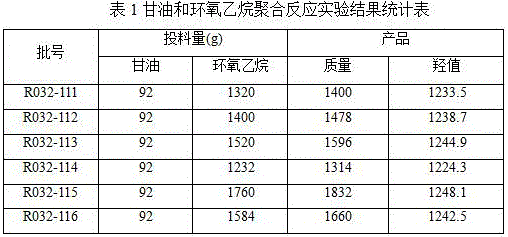

[0032] Add 92g of glycerin and 0.5g of potassium hydroxide into a 2L stainless steel kettle. After nitrogen replacement, heat up and vacuum dehydrate for 1 hour, then slowly feed ethylene oxide into a total of 1320g, control the feed rate of ethylene oxide, and maintain the reaction temperature At 140-150°C, the pressure is about 0.5MPa. After feeding, heat preservation and aging for 1 hour until the pressure in the kettle is <0MPa, then cool down and discharge, calculate the weight of the product, obtain glycerin polyoxyethylene ether monomer R032-111, and submit the hydroxyl value of the product for inspection.

Embodiment 12

[0034] Add 92g of glycerin and 0.45g of sodium hydroxide to a 2L stainless steel kettle. After nitrogen replacement, heat up and vacuum dehydrate for 1 hour, then slowly feed ethylene oxide into a total of 1400g, control the feed rate of ethylene oxide, and maintain the reaction temperature At 140-150°C, the pressure is about 0.5MPa. After feeding, heat preservation and aging for 1 hour until the pressure in the kettle is <0MPa, then cool down and discharge, calculate the weight of the product, obtain glycerol polyoxyethylene ether monomer R032-112, and submit the hydroxyl value of the product for inspection.

Embodiment 13

[0036] Add 92g of glycerin and 0.45g of sodium methoxide to a 2L stainless steel kettle. After nitrogen replacement, heat up and vacuum dehydrate for 1h, then slowly feed ethylene oxide into a total of 1520g, control the feed rate of ethylene oxide, and maintain the reaction temperature at 140-150°C, the pressure is about 0.5MPa. After the feed is completed, heat preservation and aging for 1 hour until the pressure in the kettle is <0MPa, then cool down and discharge, calculate the weight of the product, and obtain the glycerin polyoxyethylene ether monomer R032-113, and submit the hydroxyl value of the product for inspection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com