A kind of cationic styrene-acrylic primer emulsion and preparation method thereof

A cationic and styrene-acrylic technology, applied in the coating and other directions, can solve the problems of salting out or efflorescence of the wall, limited sealing effect, poor water resistance, etc., to improve speed and stability, improve stability, and excellent sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of cationic styrene-acrylic primer emulsion of the present invention comprises the following steps:

[0026] a) Preparation of pre-emulsion: under normal temperature and pressure, add 20-40% of the total mass of water and 20-60% of the total mass of emulsifier to the container with agitator, and slowly add styrene while stirring , n-butyl acrylate, isooctyl acrylate, high-density cross-linking monomer and hydrophilic monomer, then raise the temperature of the container to 80-85°C, and pre-emulsify for 10-30 minutes to obtain a pre-emulsion for later use;

[0027] b) Under normal temperature and pressure, add the remaining water and emulsifier into the reaction kettle, heat up to 86-88°C while stirring, and add 20-40% of the total mass of the azo initiator after 1-3 minutes after the temperature stabilizes. %, and continue to stir until the azo initiator is completely dissolved;

[0028]c) Add 10-20% of the total mass of the pre-emulsion obtained ...

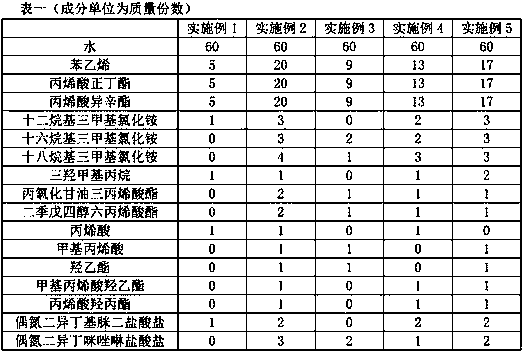

Embodiment 1

[0034] The cationic styrene-acrylic primer emulsion of the present invention comprises water, styrene, n-butyl acrylate, isooctyl acrylate, dodecyltrimethylammonium chloride, trimethylolpropane, acrylic acid, azobisisobutyl Amidine dihydrochloride, the above components are calculated in parts by mass: 60 parts of water, 5 parts of styrene, 5 parts of n-butyl acrylate, 5 parts of isooctyl acrylate, dodecyltrimethylammonium chloride 1 part, 1 part of trimethylolpropane, 1 part of acrylic acid, 1 part of azobisisobutylamidine dihydrochloride.

[0035] The preparation method of cationic styrene-acrylic primer emulsion of the present invention comprises the following steps:

[0036] a) Preparation of pre-emulsion: under normal temperature and pressure, add 20% of the total mass of water and 20% of the total mass of emulsifier to the container with agitator, and slowly add styrene and n-butyl acrylic acid while stirring Ester, isooctyl acrylate, high-density cross-linking monomer a...

Embodiment 2

[0043] The cationic styrene-acrylic primer emulsion of the present invention comprises water, styrene, n-butyl acrylate, isooctyl acrylate, lauryl trimethyl ammonium chloride, cetyl trimethyl ammonium chloride, octadecyl trimethylammonium chloride, trimethylolpropane, propoxylated glycerin triacrylate, dipentaerythritol hexaacrylate, acrylic acid, methacrylic acid, hydroxyethyl ester, hydroxyethyl methacrylate, hydroxypropyl acrylate, Azobisisobutylamidine dihydrochloride and azobisisobutylimidazoline hydrochloride, the above components are calculated in parts by mass: 60 parts of water, 20 parts of styrene, 20 parts of n-butyl acrylate, acrylic acid 20 parts of isooctyl ester, 3 parts of dodecyltrimethylammonium chloride, 3 parts of cetyltrimethylammonium chloride, 4 parts of octadecyltrimethylammonium chloride, trimethylolpropane 1 part, 2 parts of propoxylated glycerin triacrylate, 2 parts of dipentaerythritol hexaacrylate, 1 part of acrylic acid, 1 part of methacrylic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com