Corn or wheat straw converted organic bacterial manure and preparation method thereof

A technology of wheat straw and corn straw, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of bio-organic parts, to achieve the effects of increasing production and income, facilitating plant absorption, and high organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

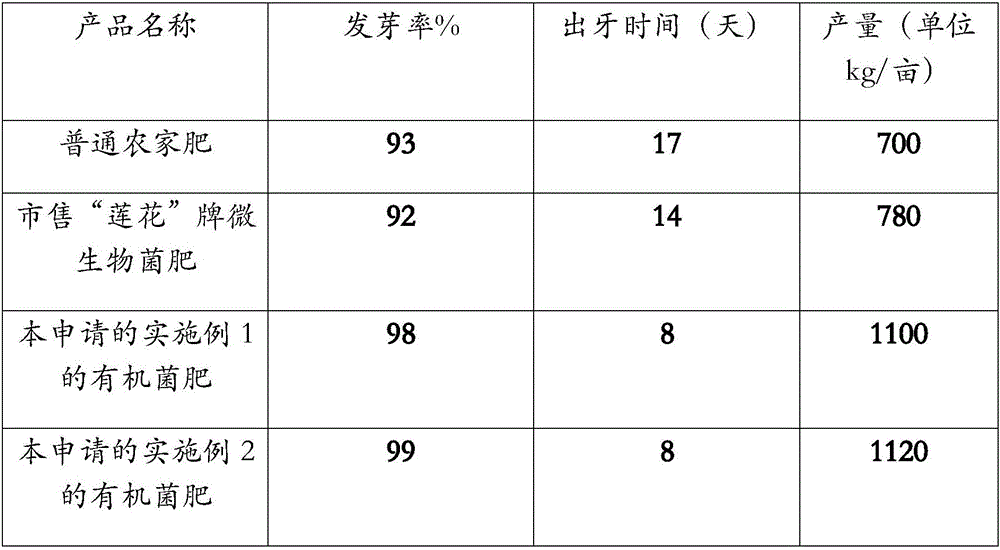

Embodiment 1

[0041] A preparation method for transforming wheat straw into organic bacterial fertilizer, comprising the steps of:

[0042] Take 100 kg of wheat straw and crush it to 80 mesh to prepare organic fertilizer.

[0043] Rhizopus 0.5 kg, actinomycetes 0.1 kg, Bacillus subtilis 2 kg, Aspergillus 0.1 kg, Bacillus licheniformis 5 kg, light and bacteria 0.1 kg, yeast 20 kg, nitrifying bacteria 0.1 kg, various trace elements ( iron, manganese, zinc, copper, magnesium, calcium) 1.1 kg;

[0044] Add 100 kg of warm water to dilute the above product, then add crushed wheat straw and stir, and stir evenly at room temperature. Add 50 kg of diluted ammonium sulfate to the well-stirred wheat straw powder and continue to stir at room temperature. After stirring evenly, pile it up in an environment where the temperature is not lower than 16 degrees, with a thickness of 0.6 meters (do not take pictures). Use cloth bags and plastic sheets After covering it for 2-4 days, it will be fermented and ...

Embodiment 2

[0047]A preparation method for transforming wheat straw into organic bacterial fertilizer, comprising the steps of:

[0048] Take 100 kg of wheat straw and crush it to 100 mesh to prepare organic fertilizer.

[0049] 0.8 kg of rhizopus, 2 kg of actinomycetes, 3 kg of Bacillus subtilis, 1 kg of Aspergillus, 8 kg of Bacillus licheniformis, 5 kg of light and bacteria, 30 kg of yeast, 0.5 kg of nitrifying bacteria, various trace elements ( iron, manganese, zinc, copper, magnesium, calcium) 3 kg;

[0050] Add 200 kg of warm water to dilute the above product, then add crushed wheat straw and stir, and stir evenly at room temperature, add 30 kg of diluted ammonium sulfate to the well-stirred wheat straw powder and continue stirring at room temperature, and then pile it up at room temperature In an environment of not lower than 16 degrees, with a thickness of 0.6 meters (do not take pictures), cover it with cloth bags and plastic cloth for 2-4 days before fermenting, and it will beco...

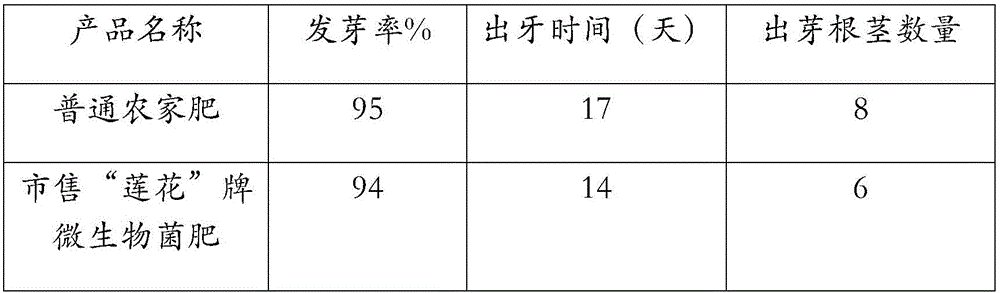

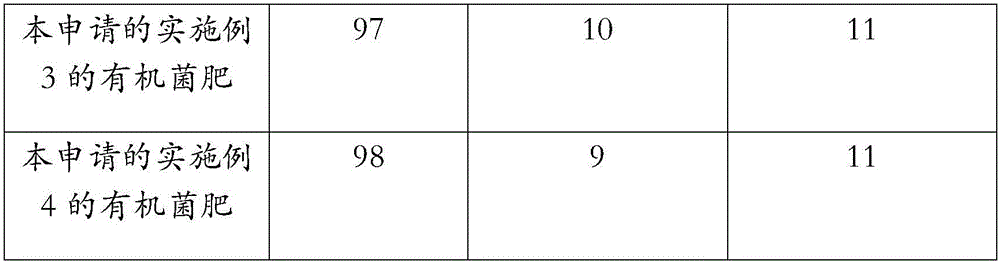

Embodiment 3

[0055] A preparation method for transforming corn stalks into organic bacterial fertilizer, comprising the steps of:

[0056] Take 100 kg of corn stalks and crush them to 60 mesh to prepare organic fertilizer.

[0057] 0.7 kg of rhizopus, 2 kg of actinomycetes, 5 kg of Bacillus subtilis, 5 kg of Aspergillus, 8 kg of Bacillus licheniformis, 4 kg of light and bacteria, 30 kg of yeast, 0.3 kg of nitrifying bacteria, various trace elements ( iron, manganese, zinc, copper, magnesium, calcium) 5 kg;

[0058] Add 150 kg of warm water to dilute the above product, then add crushed corn stalks and stir, and stir evenly at room temperature, add 45 kg of diluted ammonium sulfate to the well-stirred corn stalk powder and continue stirring at room temperature, and then pile it up at room temperature In an environment of not lower than 16 degrees, with a thickness of 0.6 meters (do not take pictures), cover it with cloth bags and plastic cloth for 2-4 days before fermenting, and it will bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com