High-infrared-emissivity ceramic and preparation method thereof

An infrared emissivity and ceramic technology, applied in the field of high infrared emissivity ceramics and their preparation, can solve the problems of limiting the application range of materials, and achieve the effects of high utilization rate, light color and high infrared emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

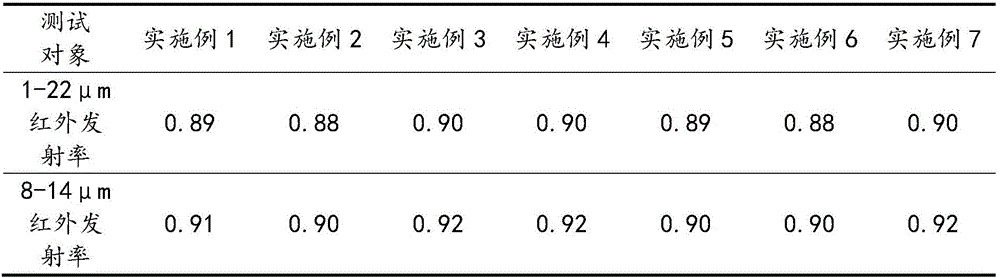

Examples

preparation example Construction

[0024] The preparation method of the high infrared emissivity ceramics of the embodiment of the present invention comprises:

[0025] Step 1: Mix the ingredients

[0026] The magnesium-rich metallurgical nickel slag is ball milled for 3-5 hours under the condition of a rotating speed of 300-500 rpm. After ball milling, 30-40% magnesium-rich metallurgical nickel slag and 30-35% Al 2 o 3 , 25-32% SiO 2 , 3-7% of Y 2 o 3 and 2-5% K 2 CO 3 Mix to obtain embryo body raw materials.

[0027] Further, preferably, 32-35% of magnesium-rich metallurgical nickel slag, 30.2-30.5% of Al 2 o 3 , 28.7-30.3% SiO 2 , 3-6% of Y 2 o 3 and 3-4% K 2 CO 3 mix.

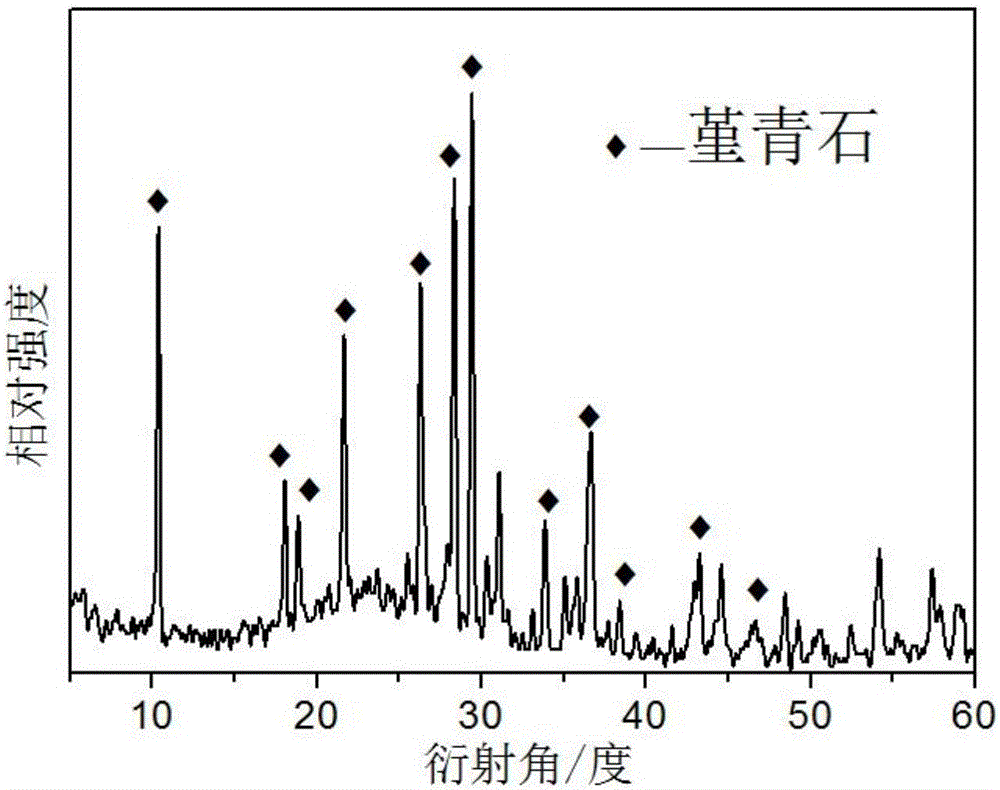

[0028] The preparation method of high infrared emissivity ceramics in the embodiment of the present invention uses magnesium-rich metallurgical nickel slag as a raw material, and can utilize iron, manganese, nickel and other elements inherent in magnesium-rich metallurgical nickel slag without adding transition metal oxides ,...

Embodiment 1

[0038] Take by weighing the raw material of 100g high infrared emissivity ceramics, take by weight percentage 32% magnesium-rich metallurgical nickel slag, 30.5% Al 2 o 3 , 28.7% SiO 2 , 3.8%Y 2 o 3 and 5%K 2 CO 3 , that is, 32g magnesium-rich metallurgical nickel slag, 30.5g Al 2 o 3 , 28.7g SiO 2 , 3.8g Y 2 o 3 and 5g K 2 CO 3 . Among them, the magnesium-rich metallurgical nickel slag comes from the solid waste slag discharged during the nickel alloy smelting process. In a preferred embodiment of the present invention, the magnesium-rich metallurgical nickel slag comprises SiO 2 、Al 2 o 3 and MgO, by weight percent, SiO 2 Accounting for 55% of the total magnesium-rich metallurgical nickel slag, Al 2 o 3 It accounts for 8% of the total amount of magnesium-rich metallurgical nickel slag, MgO accounts for 30% of the total amount of magnesium-rich metallurgical nickel slag, and the balance is iron, manganese, nickel and other elements and other solid impurities...

Embodiment 2

[0042] Take by weighing the raw material of 100g high infrared emissivity ceramics, take by weight percentage 32.8% magnesium-rich metallurgical nickel slag, 30.2% Al 2 o 3 , 29.5% SiO 2 , 5.3%Y 2 o 3 and 2.2%K 2 CO 3 , that is, 32.8g magnesium-rich metallurgical nickel slag, 30.2gAl 2 o 3 , 29.5g SiO 2 , 5.3g Y 2 o 3 and 2.2g K 2 CO 3 . Among them, the magnesium-rich metallurgical nickel slag comes from the solid waste slag discharged during the nickel alloy smelting process. In a preferred embodiment of the present invention, the magnesium-rich metallurgical nickel slag comprises SiO 2 、Al 2 o 3 and MgO, by weight percent, SiO 2 Accounting for 50% of the total magnesium-rich metallurgical nickel slag, Al 2 o 3 It accounts for 5% of the total amount of magnesium-rich metallurgical nickel slag, MgO accounts for 40% of the total amount of magnesium-rich metallurgical nickel slag, and the balance is iron, manganese, nickel and other elements and other solid imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com