A high-density gypsum block

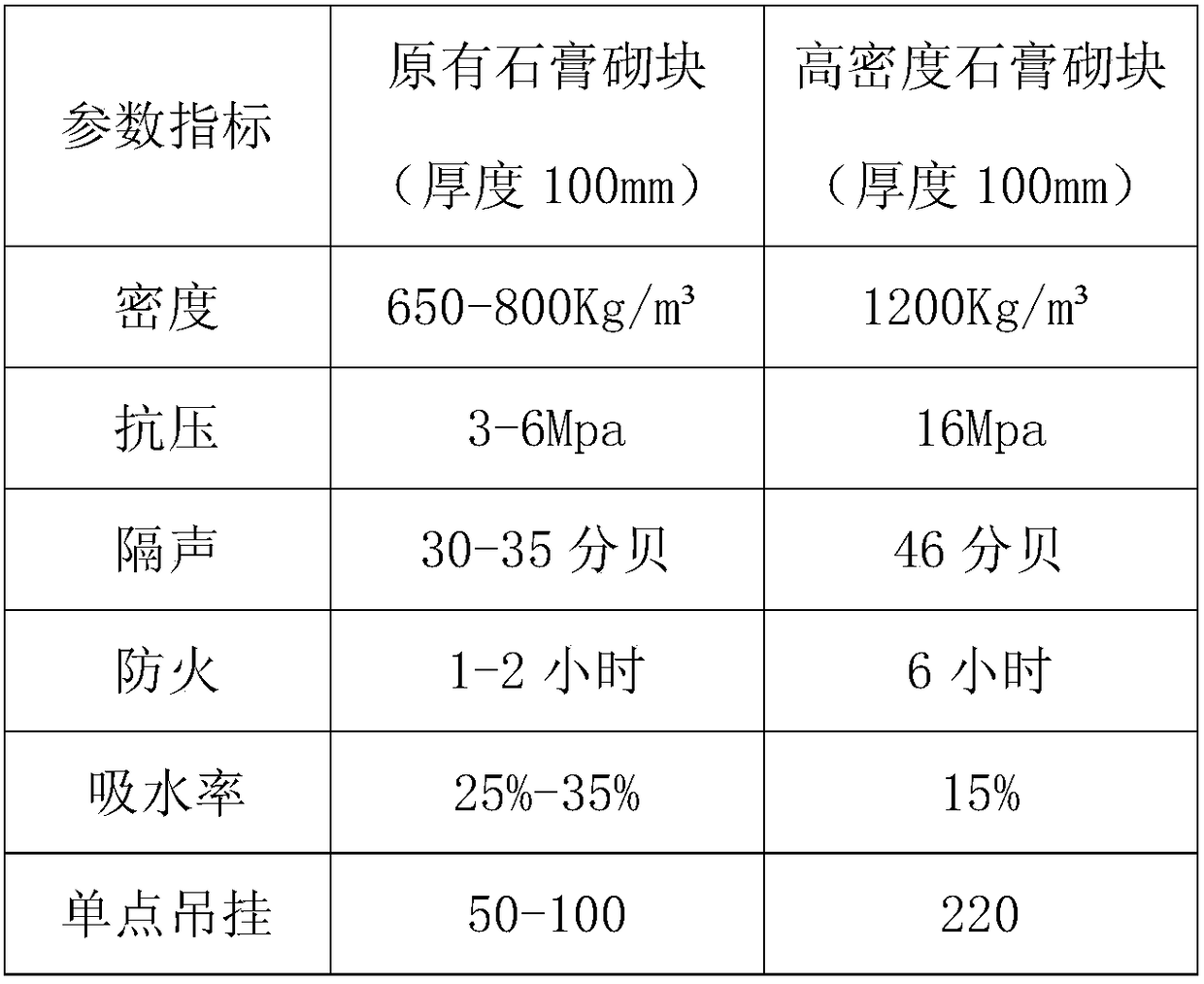

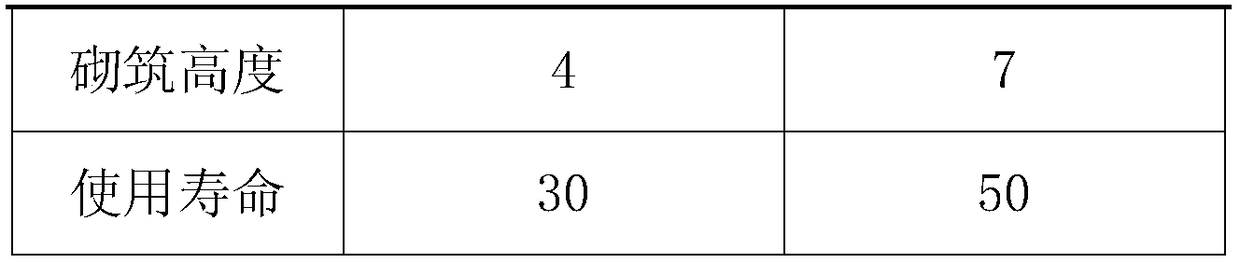

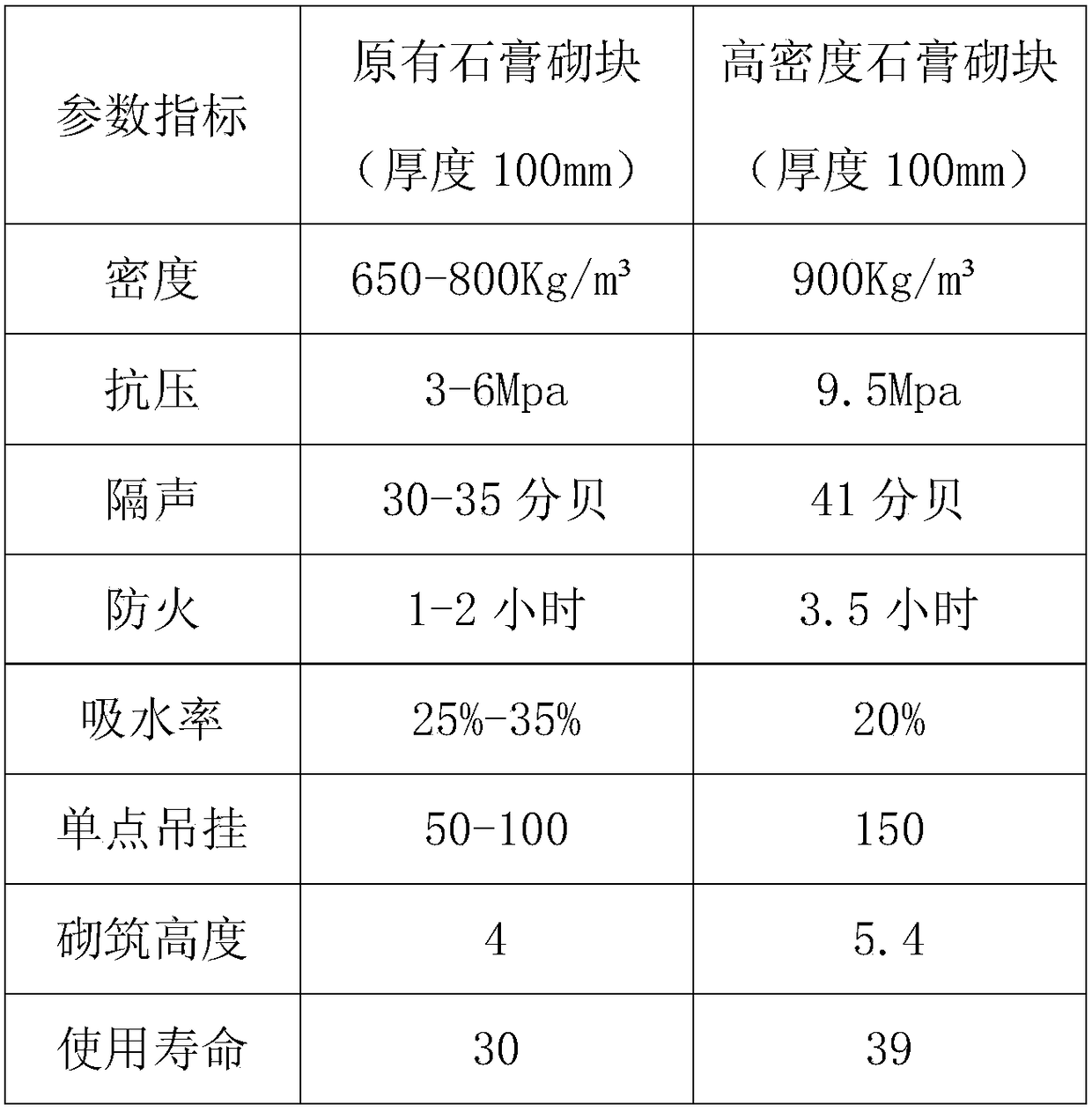

A gypsum block and high-density technology, which is applied in the field of building materials, can solve the problems that gypsum blocks cannot effectively meet people's needs, have low single-point hanging performance, and cannot guarantee firmness, etc., and achieve long comprehensive service life, Increased building height and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1: The solid raw material includes the following raw materials in parts by weight: 40KG of α gypsum powder with a mesh number of 320 mesh, 20KG of β gypsum powder with a mesh number of 250 mesh, 40KG of desulfurized gypsum powder with a mesh number of 275 mesh, and a mesh number of 400 Purpose calcium carbonate 10KG, 300 mesh calcium hydroxide 10KG, slag powder 5KG, talcum powder 5KG, cement 5KG, basic sodium carbonate 5KG, water reducing agent powder 5KG, glass fiber 2.5KG, defoamer powder 5KG; liquid The weight ratio of water to solid raw materials is 1:2, water is 76.25KG, and the water-reducer powder is polycarboxylate water-reducer powder, naphthalene-based water-reducer powder, melamine-based water-reducer powder, lignosulfonate One of water reducer powder, casein water reducer powder, sulfamate water reducer powder, acrylic water reducer powder, the defoamer powder is polyether type defoamer powder, silicone defoamer powder One of foaming agent powder and...

Embodiment 2

[0024] Example 2: 20KG of α gypsum powder with 200 mesh, 15KG of β gypsum powder with 100 mesh, 10KG of desulfurized gypsum powder with 200 mesh, 1KG of calcium carbonate with 300 mesh, and hydrogen oxidation with 250 mesh Calcium 1KG, slag powder 1KG, talcum powder 1KG, cement 1KG, basic sodium carbonate 1KG, water reducer powder 1KG, glass fiber 0.01KG, defoamer powder 1KG; the weight ratio of liquid water to solid raw materials is 2:5, Water 53.0104KG, the water-reducer powder is polycarboxylate water-reducer powder, naphthalene-based water-reducer powder, melamine-based water-reducer powder, lignosulfonate water-reducer powder, casein water-reducer powder, One of sulfamate water reducer powder and acrylic water reducer powder, the defoamer powder is polyether type defoamer powder, silicone defoamer powder, phenylethyl alcohol oleate defoamer One of the powders.

[0025] The preparation method is the same as in Example 1.

Embodiment 3

[0026] Example 3: 20KG of α gypsum powder with 250 mesh, 15KG of β gypsum powder with 150 mesh, 30KG of desulfurized gypsum powder with 250 mesh, 5KG of calcium carbonate with 350 mesh, and hydrogen oxidation with 275 mesh Calcium 5KG, slag powder 5KG, talc powder 5KG, cement 5KG, basic sodium carbonate 5KG, water reducer powder 5KG, glass fiber 1.25KG, defoamer powder 5KG; the weight ratio of liquid water to solid raw materials is 3:5, Water 47.8125KG, the water-reducer powder is polycarboxylate water-reducer powder, naphthalene-based water-reducer powder, melamine-based water-reducer powder, lignosulfonate water-reducer powder, casein water-reducer powder, One of sulfamate water reducer powder and acrylic water reducer powder, the defoamer powder is polyether type defoamer powder, silicone defoamer powder, phenylethyl alcohol oleate defoamer One of the powders.

[0027] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com