Composition used for preparing compound quartzite jewel board

A composition and quartz stone technology, applied in the field of artificial building decoration materials, can solve the problems of hardness, strength, compactness, smoothness, impermeability, toughness, flame retardancy, anti-ultraviolet aging, limited use range, etc. Strong ultraviolet reflection ability, strong infrared reflection ability, good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

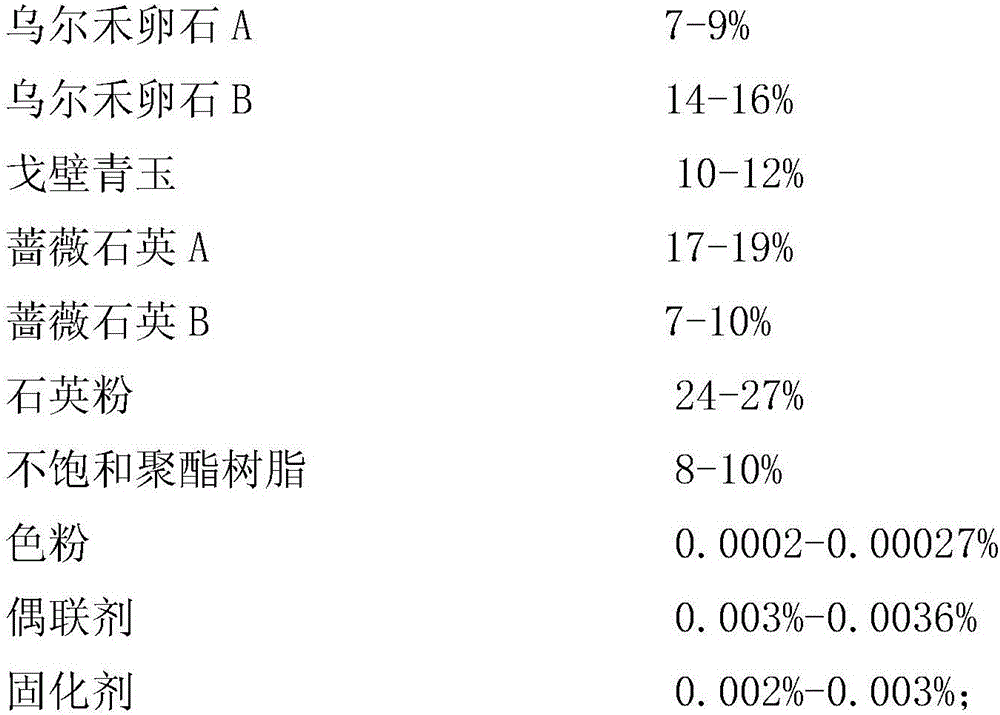

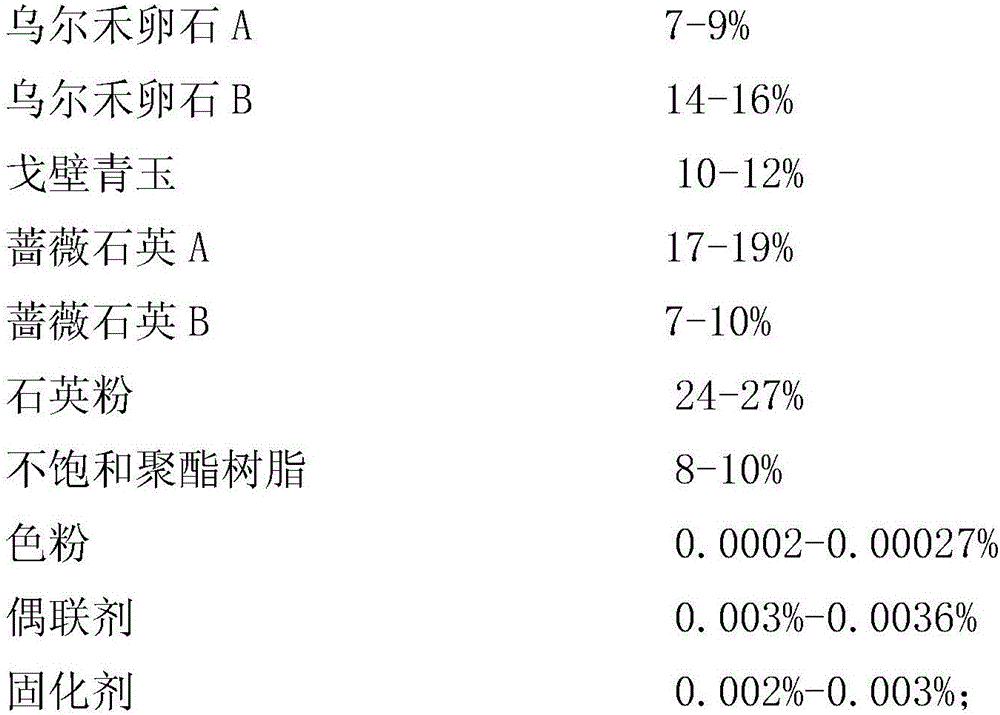

[0048] Raw material preparation:

[0049] Urho pebble A: The deep red Urho pebble produced in Karamay. Pass through a 4-mesh sieve after crushing; weigh 7kg.

[0050] Urho pebble B: The red Urho pebble produced in Karamay, crushed and passed through an 8-mesh sieve. Weigh 14kg.

[0051] Gobi sapphire: the translucent green Gobi sapphire produced in Altay, crushed and passed through a 26-mesh sieve. Weigh 10kg.

[0052] Rose Quartz A: reddish rose quartz produced in Altay, crushed and passed through a 40-mesh sieve. Weigh 17kg.

[0053] Rose Quartz B: reddish rose quartz produced in Altay, crushed and passed through a 70-mesh sieve. Weigh 7kg.

[0054] Quartz powder: quartz powder with a mesh number of 300 mesh. Weigh 24kg.

[0055] Unsaturated polyester resin: use o-phthalic unsaturated polyester resin, weighing 8kg.

[0056] Toner: adopt fruit green toner, weigh 0.0002kg.

[0057] Coupling agent KH-570: Weigh 0.003kg of coupling agent KH-570.

[0058] Curing agent...

Embodiment 2

[0073] Raw material preparation:

[0074] Urho Pebble A: The deep red Urho Pebble produced in Karamay, crushed and passed through a 6-mesh sieve; weigh 9kg;

[0075] Urho Pebble B: Urho pebbles of reddish color produced in Karamay, crushed and passed through a 16-mesh sieve; weigh 16kg;

[0076] Gobi sapphire: the translucent green Gobi sapphire produced in Altay, crushed and passed through a 40-mesh sieve; weigh 12kg;

[0077] Rose Quartz A: reddish rose quartz produced in Altay, crushed and passed through a 70-mesh sieve; weigh 19kg;

[0078] Rose Quartz B: reddish rose quartz produced in Altay, crushed and passed through a 120-mesh sieve; weigh 10kg;

[0079] Quartz powder: quartz powder with a mesh number of 350; weigh 27kg;

[0080] Unsaturated polyester resin: use isophthalic unsaturated polyester resin, weigh 10kg;

[0081] Toner: use phthalocyanine blue toner, weighing 0.00027kg;

[0082] Coupling agent KH-570: Weigh 0.0036kg of coupling agent KH-570;

[0083] Cu...

Embodiment 3

[0098] Raw material preparation:

[0099] Urho pebble A: The deep red Urho pebble produced in Karamay, crushed and passed through a 4-mesh sieve; weigh 8kg;

[0100] Uerhe Pebble B: Urhe pebbles of reddish color produced in Karamay, crushed and passed through a 12-mesh sieve; weigh 15kg;

[0101] Gobi sapphire: the translucent green Gobi sapphire produced in Altay, crushed and passed through a 32-mesh sieve; weigh 11kg;

[0102] Rose quartz A: reddish rose quartz produced in Altay, crushed and passed through a 50-mesh sieve; weigh 18kg;

[0103] Rose Quartz B: reddish rose quartz produced in Altay, crushed and passed through a 100-mesh sieve; weigh 8kg;

[0104] Quartz powder: quartz powder with a mesh number of 325; weigh 25kg;

[0105] Unsaturated polyester resin: adopt p-benzene type unsaturated polyester resin, weigh 9kg;

[0106] Toner: use Luo-green toner, weighing 0.00025kg;

[0107] Coupling agent KH-570: Weigh 0.0032kg of coupling agent KH-570;

[0108] Curing age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com