G-C3N4 nanosheet with monodisperse structure and preparation method of g-C3N4 nanosheet

A nanosheet, monodisperse technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low yield, long time, difficult to be separated and dried powder, etc., to achieve high yield, Uniform particle distribution and high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A monodisperse structure g-C 3 N 4 Nano sheet and preparation method thereof, concrete steps are as follows:

[0025] (1) One-time calcination: using melamine as raw material, put the raw material in a sintered boat, then place the sintered boat in a muffle furnace, and calcine at 550°C in air for 4 hours to obtain g-C 3 N 4 meal;

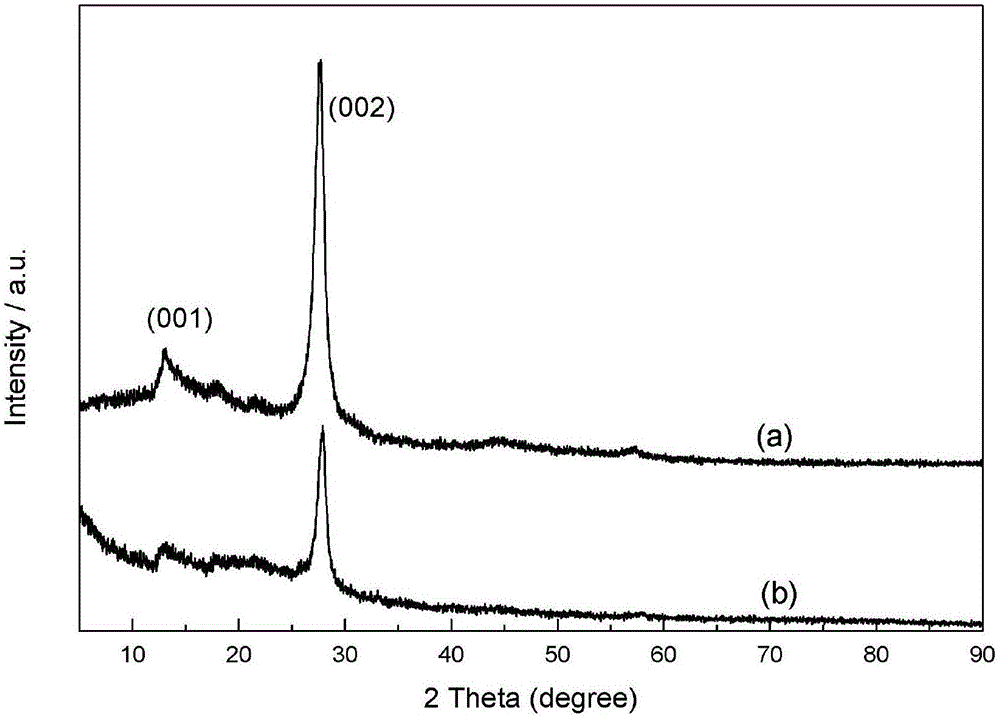

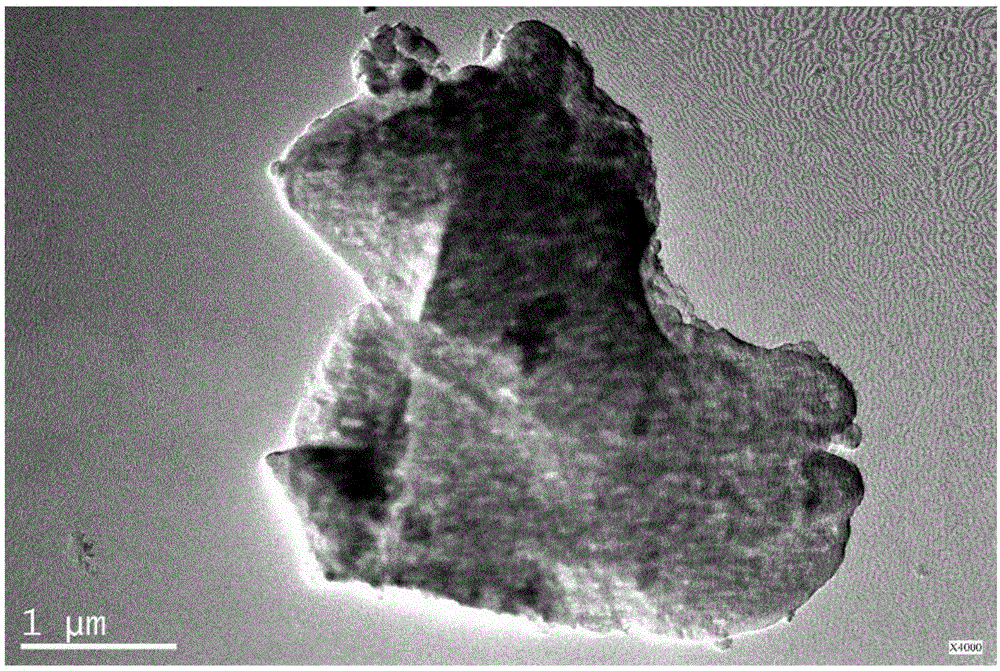

[0026] The g-C obtained in step (1) 3 N 4 Coarse powder looks like figure 2 As shown, it is mainly agglomerated powder with a size of micron.

[0027] (2) secondary calcination: with g-C in step (1) 3 N 4 Coarse powder is used as the raw material, the raw material is placed in a burning boat, and then the burning boat is placed in a sealed tube furnace, nitrogen is used as the carrier gas, nitrogen is passed through distilled water, and then enters the sealed tube furnace for calcination at 500°C for 2 hours , to obtain the monodisperse structure g-C 3 N 4 Nanosheets.

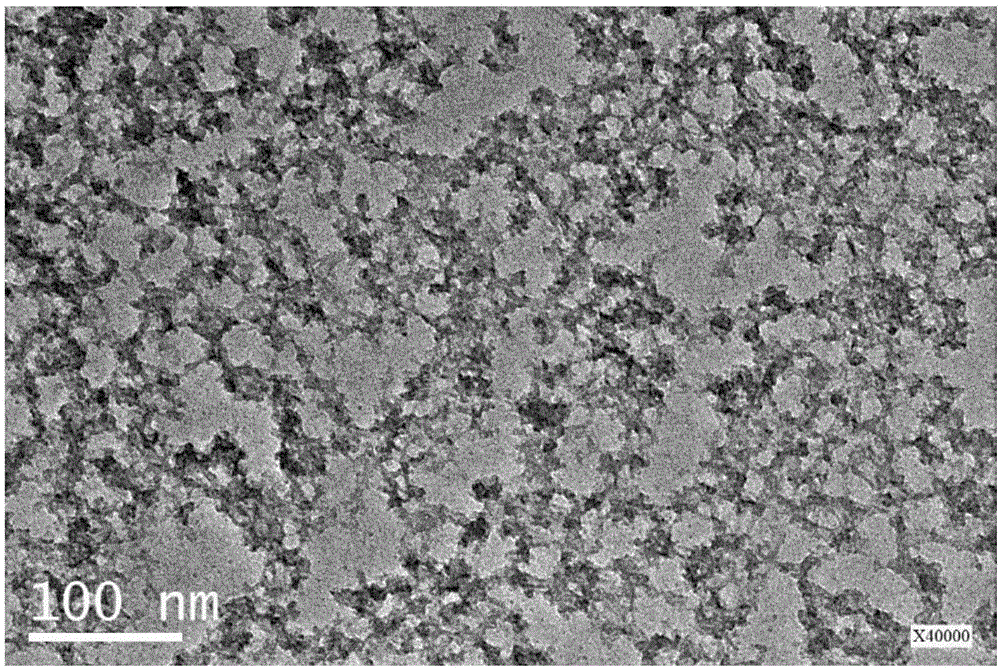

[0028] The g-C obtained in step (2) 3 N 4 Nanosheets look...

Embodiment 2

[0031] The preparation method of this embodiment is the same as that of Example 1, except that the melamine in step (1) is modified to urea.

[0032] g-C prepared in this embodiment 3 N 4 The specific surface area of the nanosheet is 206m 2 g -1 , has a strong photocatalytic ability, under visible light conditions, the complete degradation of 20mg / L rhodamine B can be achieved within 10min, and the hydrogen production efficiency of photolysis water is 1157μmol·g -1 h -1 .

Embodiment 3

[0034] The preparation method of the present embodiment is the same as that of Example 1, except that the melamine in the step (1) is modified into dicyandiamide.

[0035] g-C prepared in this embodiment 3 N 4 The specific surface area of the nanosheet is 220m 2 g -1 , has a strong photocatalytic ability, under visible light conditions, the complete degradation of 20mg / L rhodamine B can be achieved within 10min, and the hydrogen production efficiency of photolysis water is 1162μmol·g -1 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com