Method for preparing gas-phase hydrogen chloride by utilizing chlorosilane residue

A chlorosilane residual liquid, hydrogen chloride technology, applied in chlorine/hydrogen chloride, preparation with chloride, chemical instruments and methods, etc., can solve the problems of difficult separation, waste of chlorosilane residual liquid resources, narrow use range, etc., and achieve high efficiency Collection and generation of simple and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

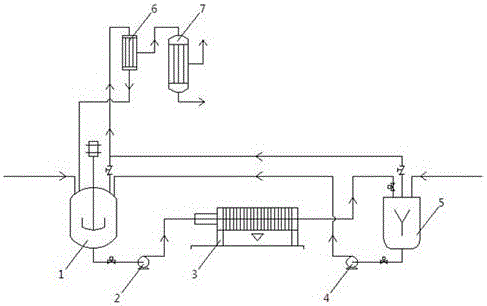

Image

Examples

Embodiment 1

[0030] A method for producing gaseous hydrogen chloride by using chlorosilane raffinate described in this embodiment specifically comprises the following steps: Utilize industrial concentrated sulfuric acid to prepare 1000 g of 20% sulfuric acid and place it in stirring reactor 1, slowly add 3200 g of chlorosilane raffinate dropwise The mixed gas generated by the reaction enters the condenser 6, adjusts the temperature of the condenser at -15°C, condenses the liquid state and returns it to the stirred reactor 1 to continue hydrolysis, and the gas phase material enters the high-pressure separator 7 to adjust the separation The pressure of the device is 2.4Mpa. The vacuum acid-resistant bottle is used to collect the liquid material separated by the high-pressure separator, and the hydrogen gas storage is used to collect the separated hydrogen. After the collection is completed, the weight of the acid-resistant bottle is increased by 2501.3g. The calculation shows that the recovery...

Embodiment 2

[0033] A method for producing gas-phase hydrogen chloride by utilizing chlorosilane raffinate described in this embodiment specifically comprises the following steps: Utilize industrial concentrated sulfuric acid to prepare 1000 g of 40% sulfuric acid and place it in stirring reactor 1, slowly add 2000 g of chlorosilane raffinate dropwise The mixed gas generated by the reaction enters the condenser 6, adjusts the temperature of the condenser at -20°C, condenses the liquid state and returns it to the stirred reactor 1 to continue hydrolysis, and the gas phase material enters the high-pressure separator 7 to adjust the separation The pressure of the device is 2.0Mpa. Use the vacuum acid-resistant bottle to collect the liquid material separated by the high-pressure separator, and use the hydrogen storage to collect the separated hydrogen. After the collection, the weight of the acid-resistant bottle increases by 1572.4g. The calculation shows that the recovery rate of hydrogen chlo...

Embodiment 3

[0036] A method for producing gas-phase hydrogen chloride by utilizing chlorosilane raffinate described in this embodiment specifically comprises the following steps: Utilize industrial concentrated sulfuric acid to prepare 1000 g of 60% sulfuric acid and place it in stirring reactor 1, slowly add 880 g of chlorosilane raffinate dropwise The mixed gas generated by the reaction enters the condenser 6, adjusts the temperature of the condenser at -30°C, condenses the liquid state and returns it to the stirred reactor 1 to continue hydrolysis, and the gas phase material enters the high-pressure separator 7 to adjust the separation The pressure of the device is 2.2Mpa. Use a vacuum acid-resistant bottle to collect the liquid material separated by the high-pressure separator, and use a hydrogen storage to collect the separated hydrogen. After the collection, the weight of the acid-resistant bottle increases by 679.2g. The calculation shows that the recovery rate of hydrogen chloride i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com