A garbage compression device and a rear-loading compression garbage truck

A technology of garbage compression and back door, which is applied in the directions of garbage receptacle, transportation and packaging, etc. It can solve the problems of the compression stroke limitation of the compression mechanism, occupying the space of the collecting box, and the compression stroke of the compression mechanism is small, etc., so as to improve the rationality of the bearing force. , Increase the amount of garbage collected, and improve the effect of driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

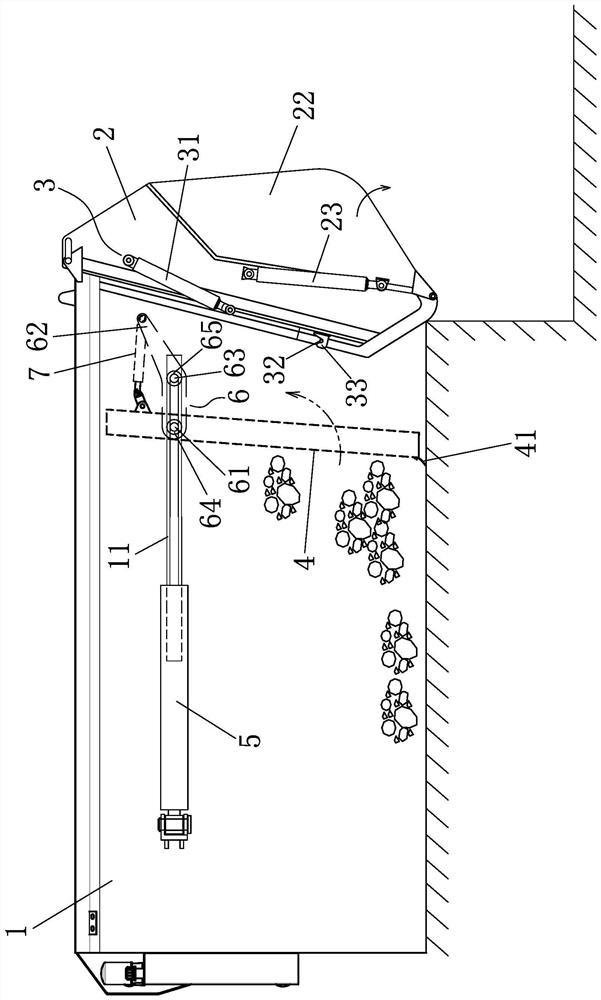

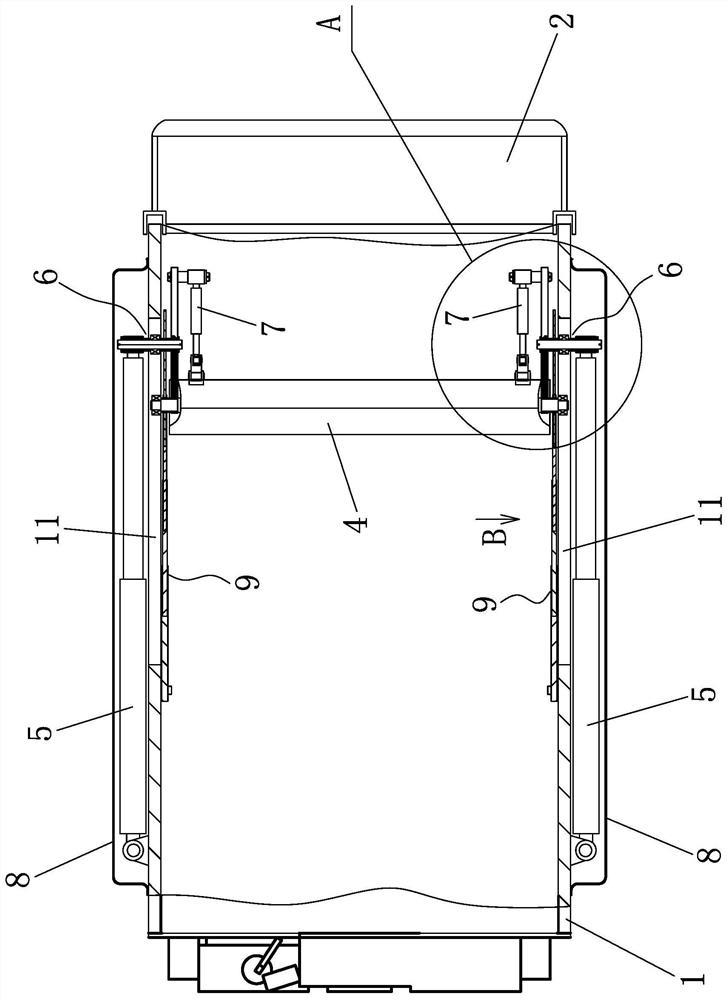

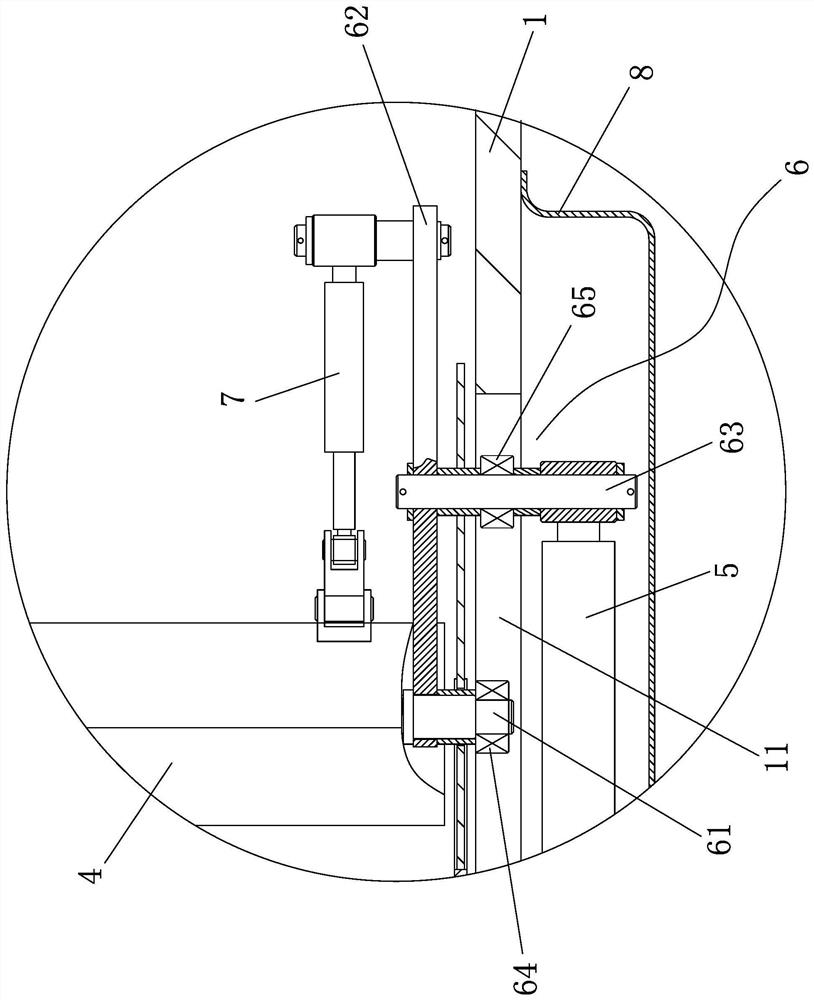

[0027] Figure 1 to Figure 5 As shown, a garbage compressing device includes a box body 1, a rear door 2 is hinged to the rear of the box body 1, a rear door opening or closing mechanism 3 is installed between the rear door 2 and the box body 1, and the rear door 2 is provided with a garbage feeding Port 21, a push plate 4 is installed in the box body 1, and two driving parts are symmetrically installed on the two outer sides of the box body 1. The components of the driving force; two long horizontal through holes 11 are opened on the two sides of the box 1 corresponding to the two push-pull cylinders 5; The push-pull cylinder 5 is connected to the outside, and the push-pull cylinder 5 drives the moving assembly 6 to move along the long horizontal through hole 11 . A rotating oil cylinder 7 is also installed between the sides. One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com