Faucet oil pressure brake device

A faucet and brake technology, used in bicycle accessories, bicycle brakes, etc., can solve the problems of the large brake master cylinder and the inability to match the concealment of the brake line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

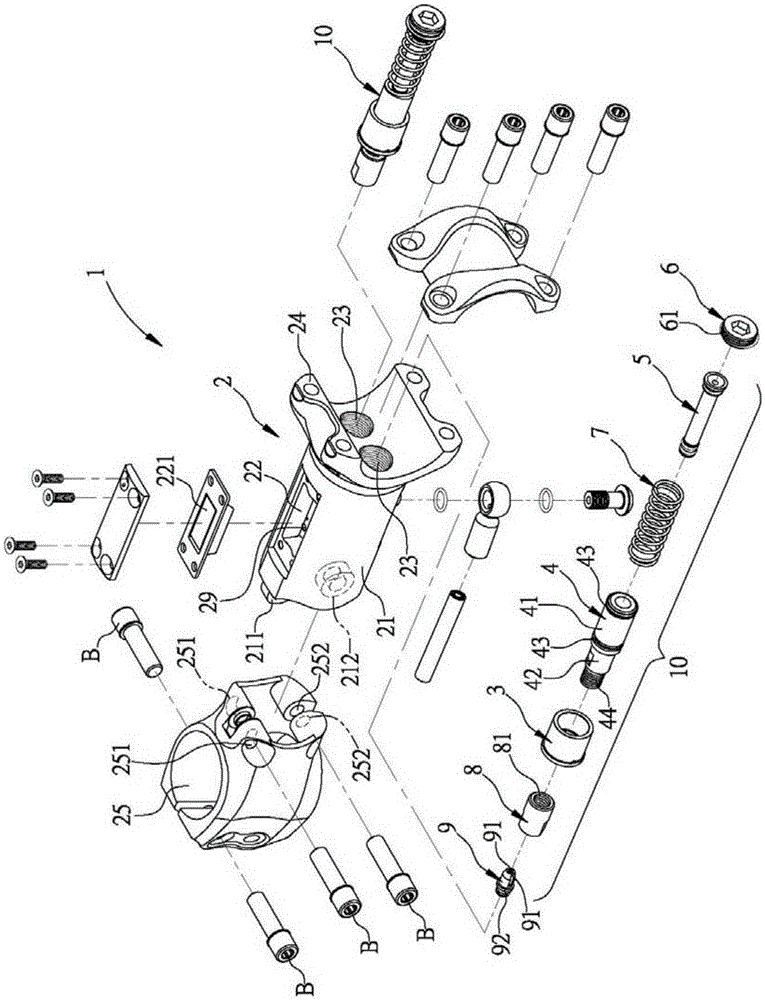

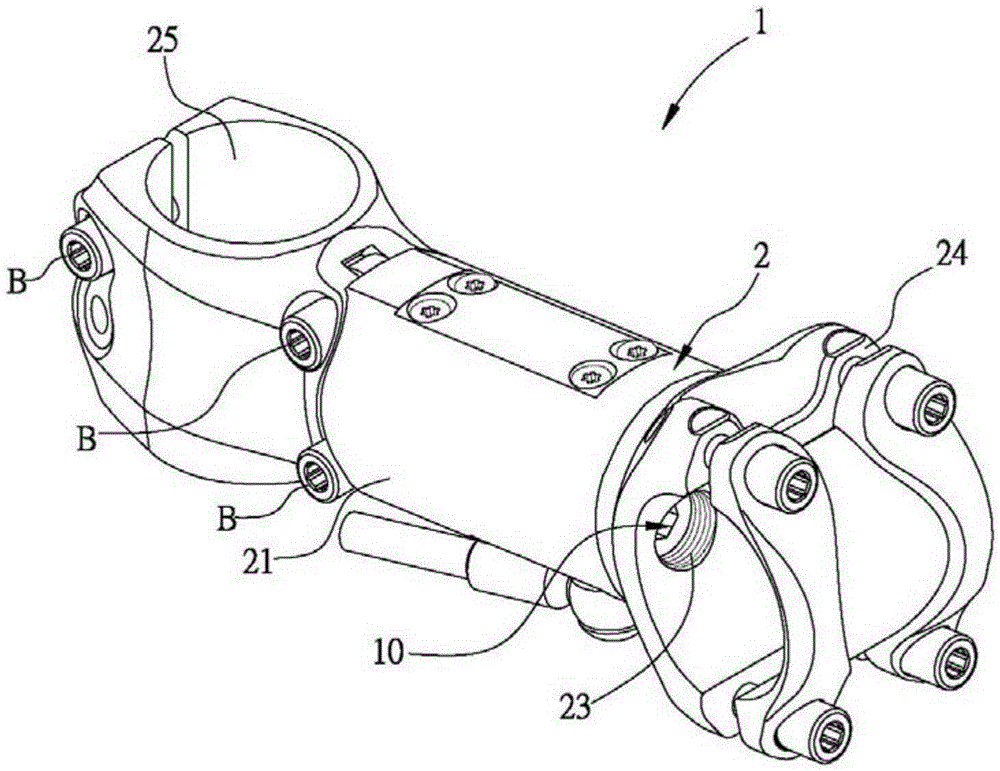

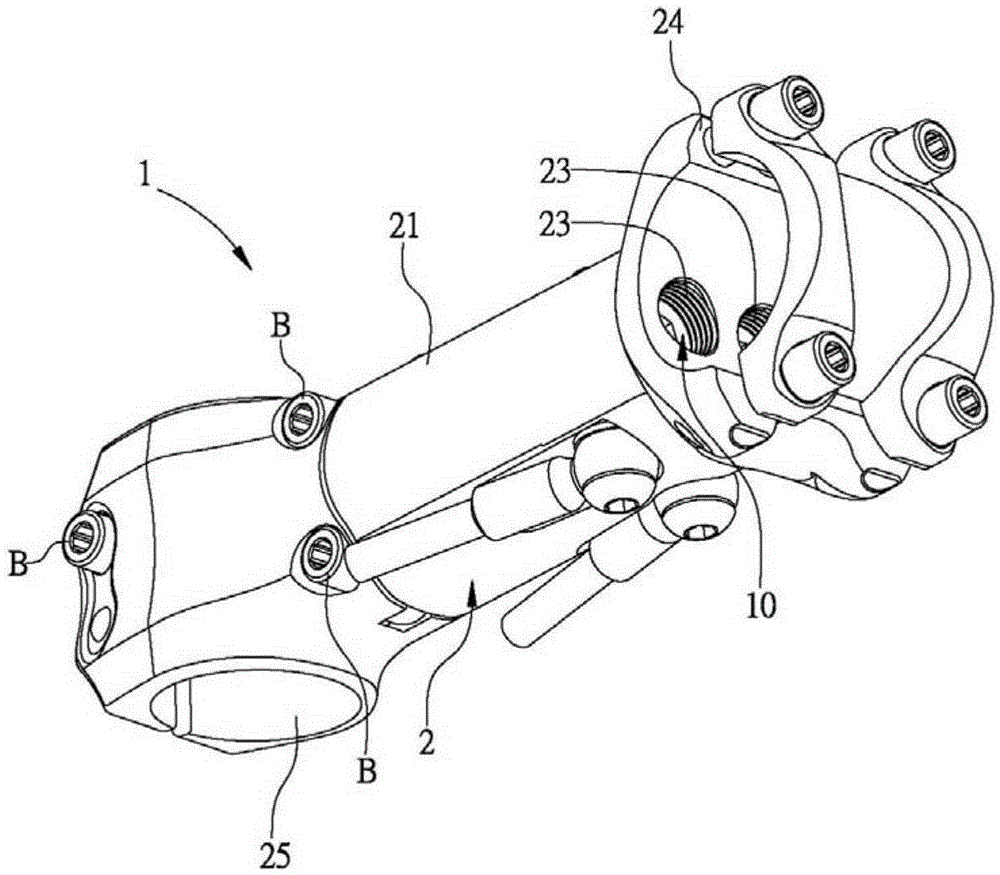

[0033] figure 1 It is an exploded schematic view of the faucet hydraulic brake device of the present invention. figure 2 It is a schematic top view of the faucet hydraulic brake device of the present invention. image 3 It is a schematic bottom view of the faucet hydraulic brake device of the present invention. Figure 4 It is a schematic cross-sectional view of the faucet hydraulic brake device of the present invention. Figure 5 It is a schematic diagram showing that the faucet hydraulic brake device of the present invention is connected to the faucet handle and the front fork. Figure 6 It is a schematic diagram of adjusting the angle of the faucet hydraulic brake device of the present invention. Figure 7 It is a schematic diagram of a second embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com