A kind of long-acting environment-friendly release agent and preparation method thereof

A release agent and an environmentally friendly technology, which is applied in the field of long-acting and environmentally friendly release agents and their preparation, can solve the problems of easy transfer, failure, and environmental pollution by release agents, and achieve firm adhesion, eliminate health hazards, The effect of low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

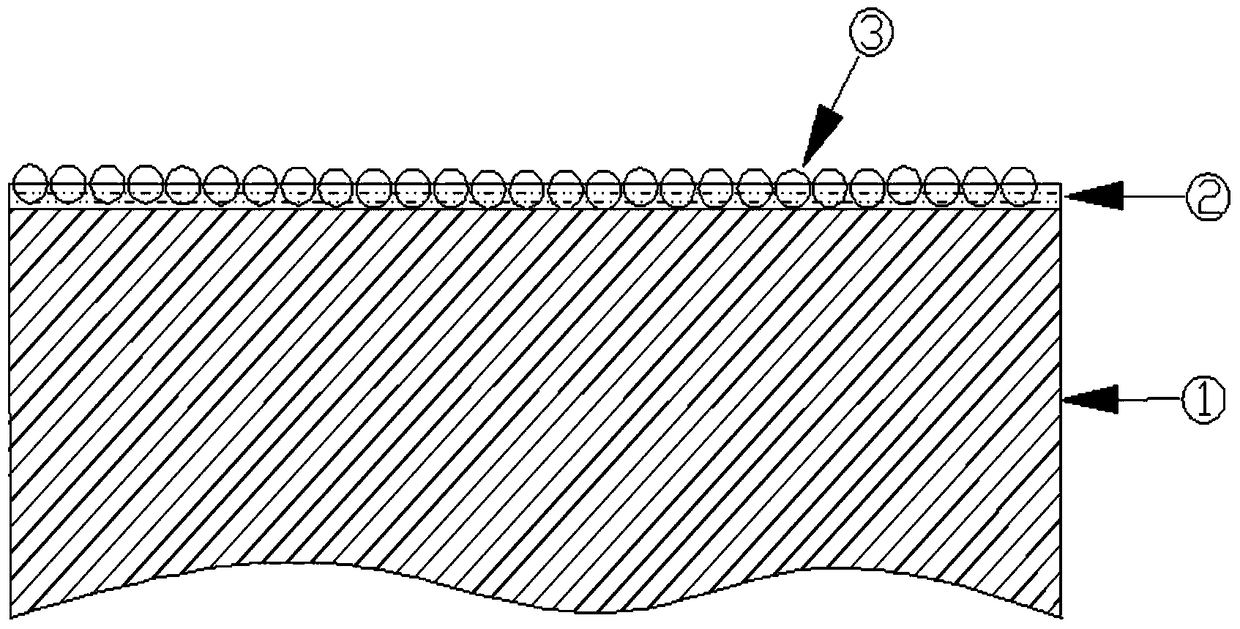

Image

Examples

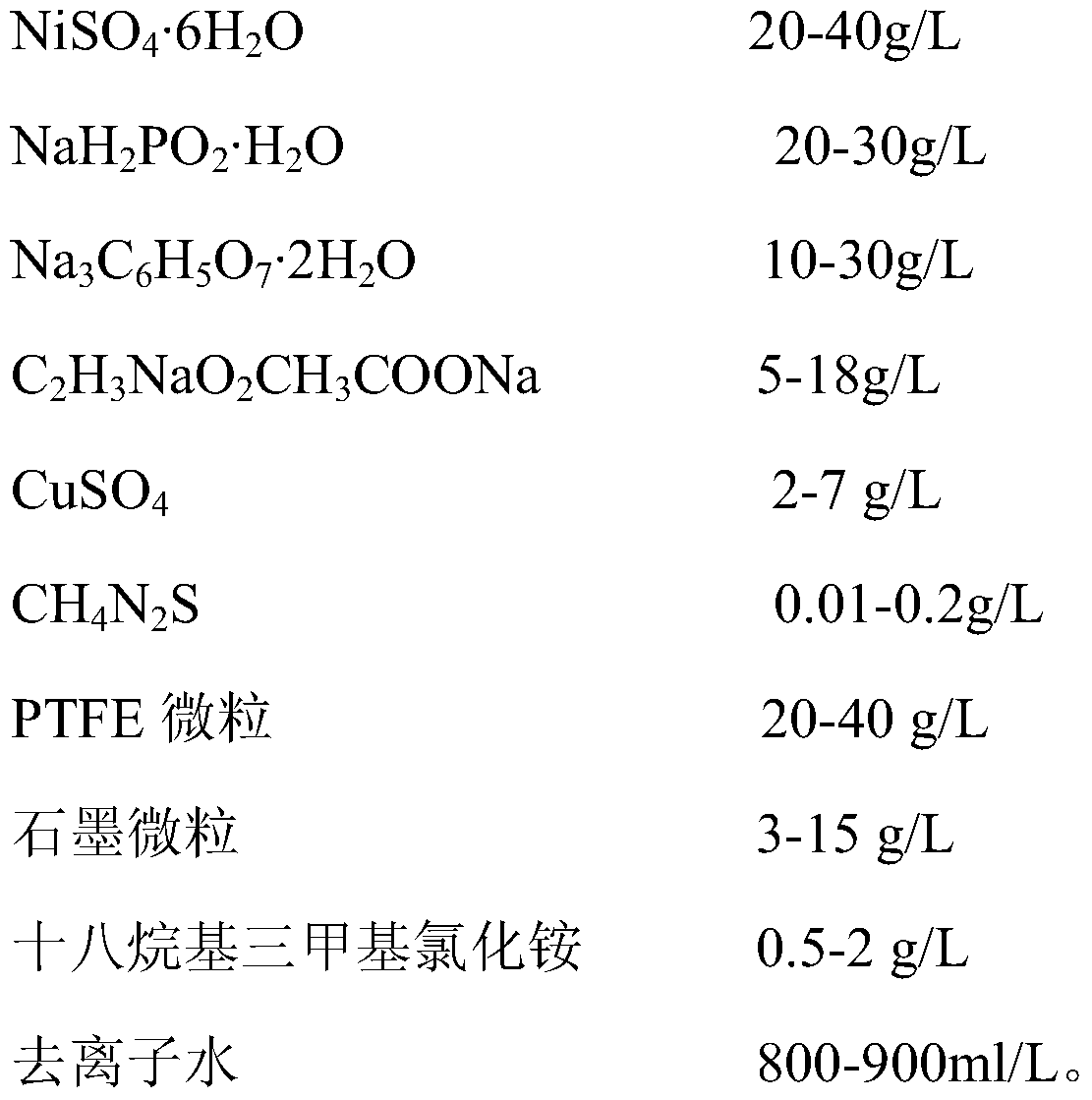

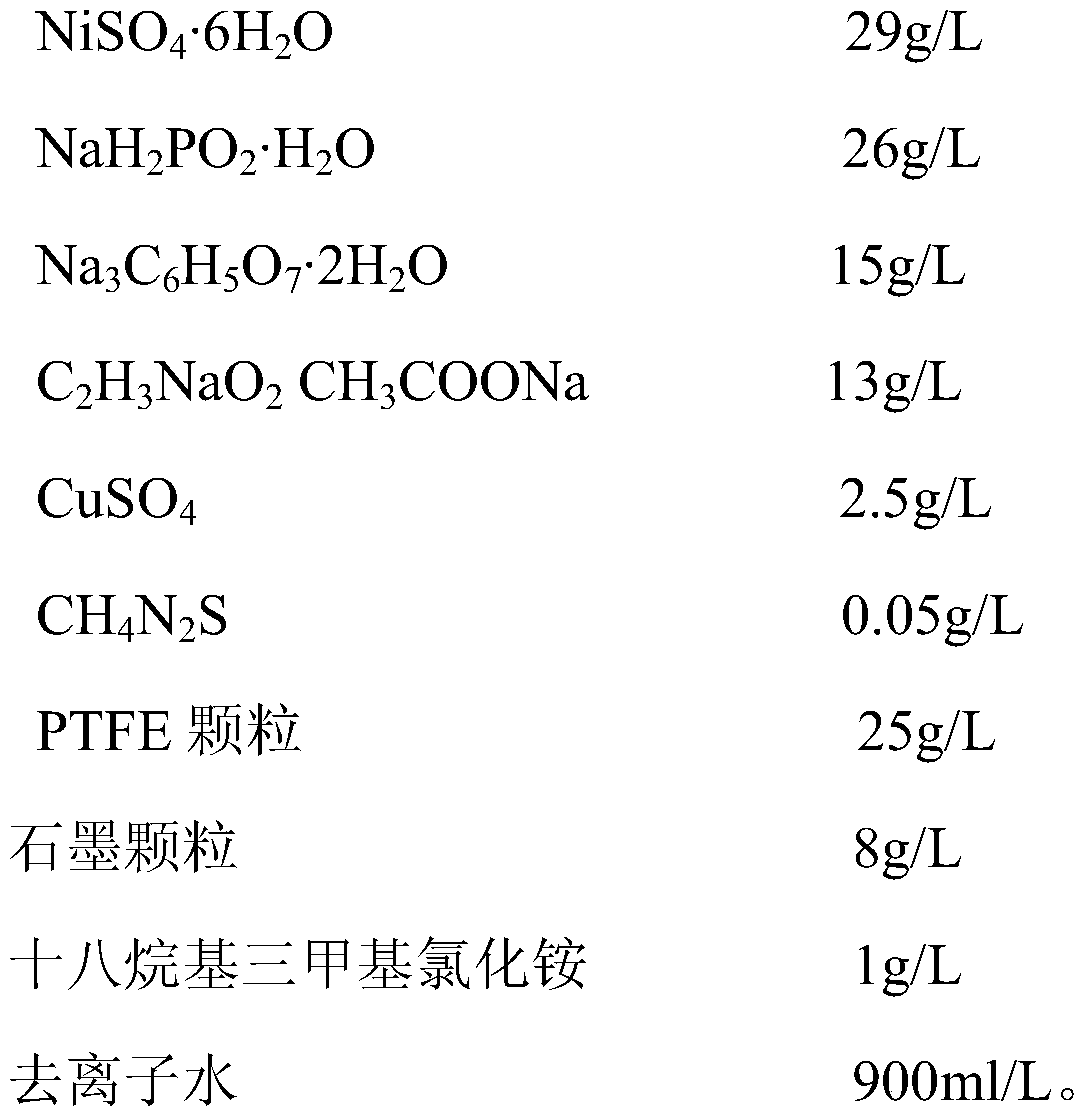

Embodiment 1-5

[0031] The preparation method of embodiment 1-5 is:

[0032] Weigh each component according to the proportion, heat deionized water to 45-55°C in a water bath, first add octadecyltrimethylammonium chloride to dissolve, and stir thoroughly, then add graphite particles and PTFE particles Stir fully, and finally add the rest of the medicament, stop heating and continue stirring. After the temperature of the mixture drops to room temperature, put it into a pressure tank according to the amount of 300ml per portion, and pour high-purity nitrogen as a propellant to make the pressure in the tank reach 0.3- 0.5MPa is enough.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com