Preparation method of titanium or titanium alloy powder with micro-hydrogenated surface

A titanium alloy and powder technology, which is applied in the field of preparation of titanium or titanium alloy powder, can solve the problem of uncontrollable hydrogen absorption process of double-layer atomization nozzles, achieve good fluidity and oxidation resistance, improve safety, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

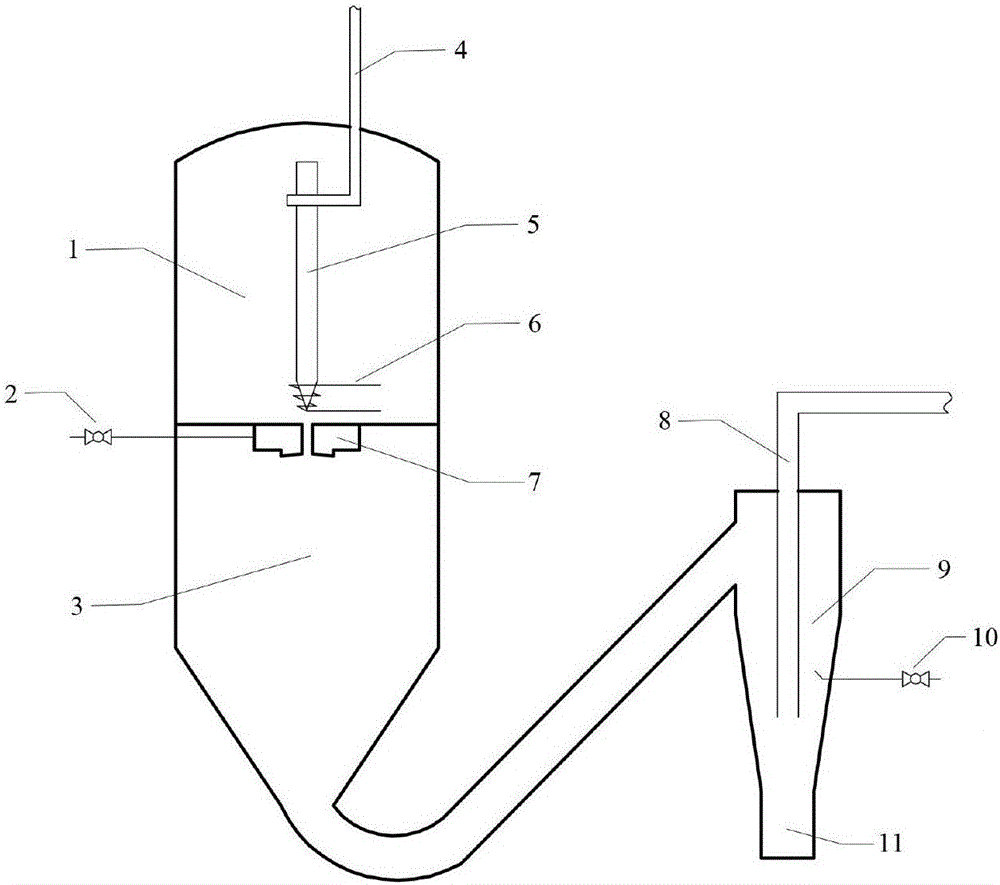

[0017] A method for preparing surface micro-hydrogenated titanium or titanium alloy powder is carried out according to the following steps:

[0018] (1) According to milling needs and equipment requirements, such as figure 1 , Prepare low-pollution and specific size titanium or titanium alloy rods 5 in advance;

[0019] (2) Pre-evacuate the melting chamber 1, atomization chamber 3 and cyclone 9 in the atomization device, and wait until the vacuum degree reaches 1×10 -4 ~1×10 -2 Pa, filled with 0.09MPa high-purity inert gas protection through the atomization gas valve 2 to prevent the oxidation of the powder during the atomization process;

[0020] (3) The lower end of the titanium or titanium alloy rod 5 is heated and melted by the induction coil 6, and a stable liquid flow is formed by controlling the feeding rod 4, and then atomized and powdered through the atomizing nozzle 7 using high-purity inert gas as the medium , The atomization pressure is controlled at 3~8MPa;

[0021] (4) T...

Embodiment 1

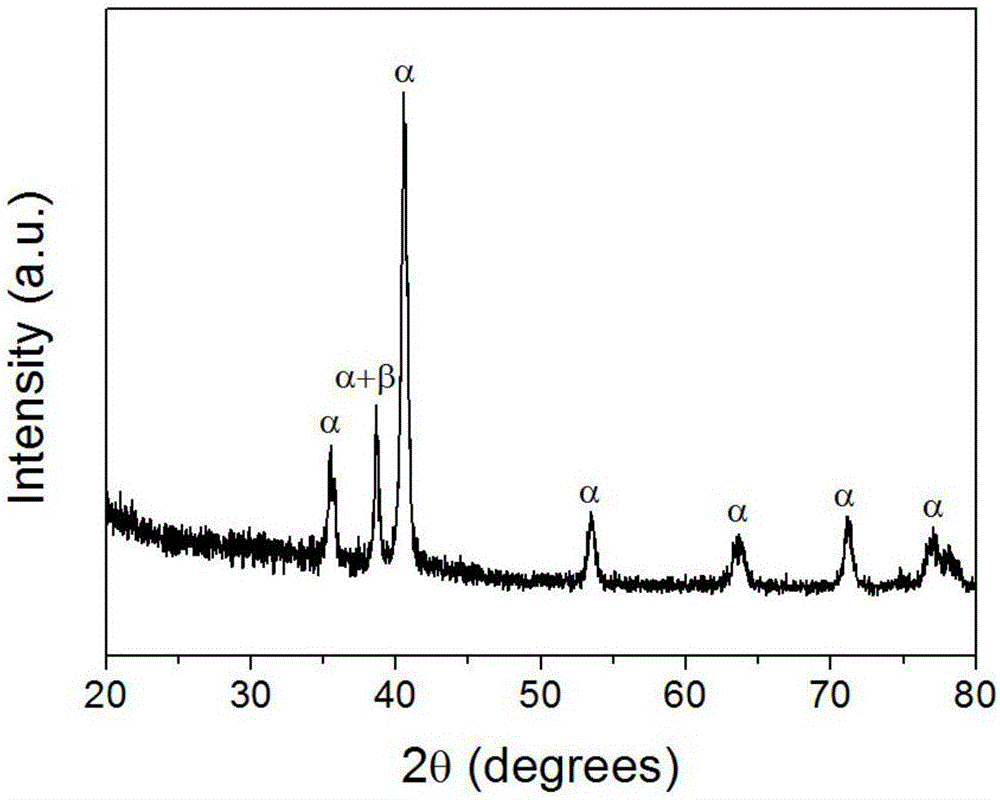

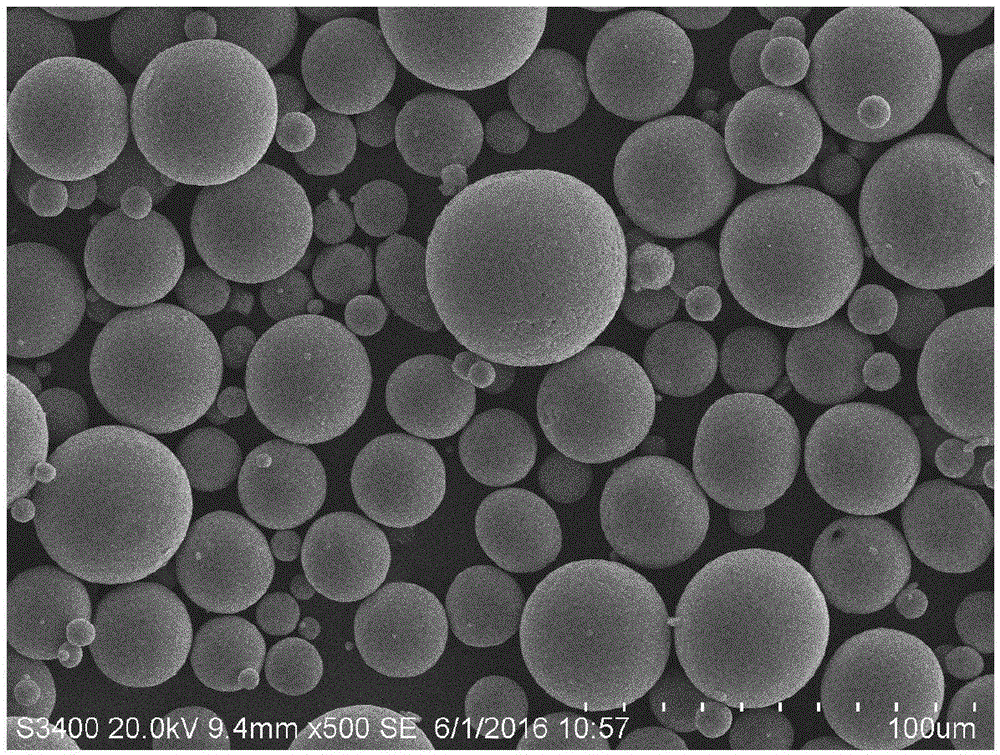

[0025] The crucible-free gas atomization method was used to prepare Ti-6Al-4V(TC4) alloy powder with surface micro-hydrogenation.

[0026] Take the TC4 titanium alloy rod with a diameter of 40mm and an impurity content of less than 0.1% as the raw material, pre-evacuate the atomization equipment until the vacuum degree reaches 1×10 -4 Pa, filled with 0.09MPa high-purity argon protection to prevent oxidation. The lower end of the titanium alloy rod is heated and melted by the induction coil to form a stable liquid flow, and then the powder is atomized through an atomizing nozzle using high-purity argon as the medium. The atomization pressure is controlled at 5-7MPa, and the atomization is completed. Titanium alloy powder is carried into the cyclone separator by airflow. The lower part of the cyclone separator is fed with a 0.3MPa hydrogen content of 10at.% hydrogen and argon mixed gas. The position of the air inlet should be 10cm higher than the exhaust port in the cyclone. And us...

Embodiment 2

[0028] The crucible-free gas atomization method prepares Ti-45Al-2Cr-8Nb alloy powder with micro-hydrogenation on the surface.

[0029] Take Ti-45Al-2Cr-8Nb titanium alloy rod with a diameter of 40mm and an impurity content of less than 0.1% as the raw material, pre-evacuate the atomization equipment until the vacuum degree reaches 1×10 -4 Pa, filled with 0.09MPa high-purity helium to protect it from oxidation. The lower end of the titanium alloy rod is heated and melted by the induction coil to form a stable liquid flow, and then the powder is atomized through an atomizing nozzle with high-purity helium as the medium, and the atomization pressure is controlled at 6-8MPa, and the atomization is completed Titanium alloy powder is carried into the cyclone separator by the air flow. The lower part of the cyclone separator is fed with a mixture of hydrogen and helium with a hydrogen content of 0.5 MPa and 25 at.%. The position of the air inlet should be 20 cm higher than the exhaust p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com