An automatic winding system for a helical half pipe

A helical and automatic technology, applied in the field of automatic spiral half-pipe winding system, can solve the problems of frequent manual movement, uneven pitch of half-pipes, high labor intensity, etc., and achieve the effects of simple and accurate winding, reduced labor, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

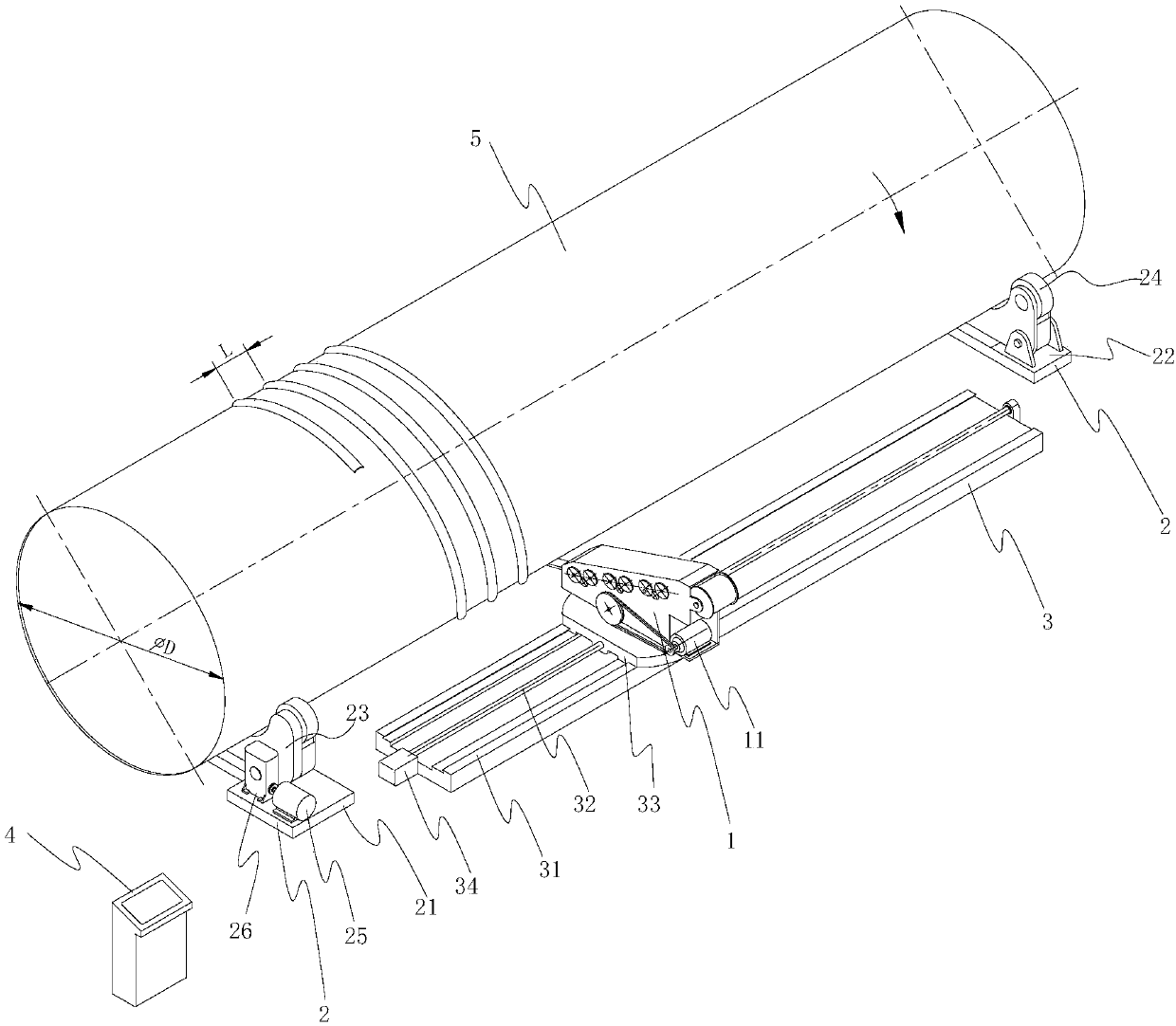

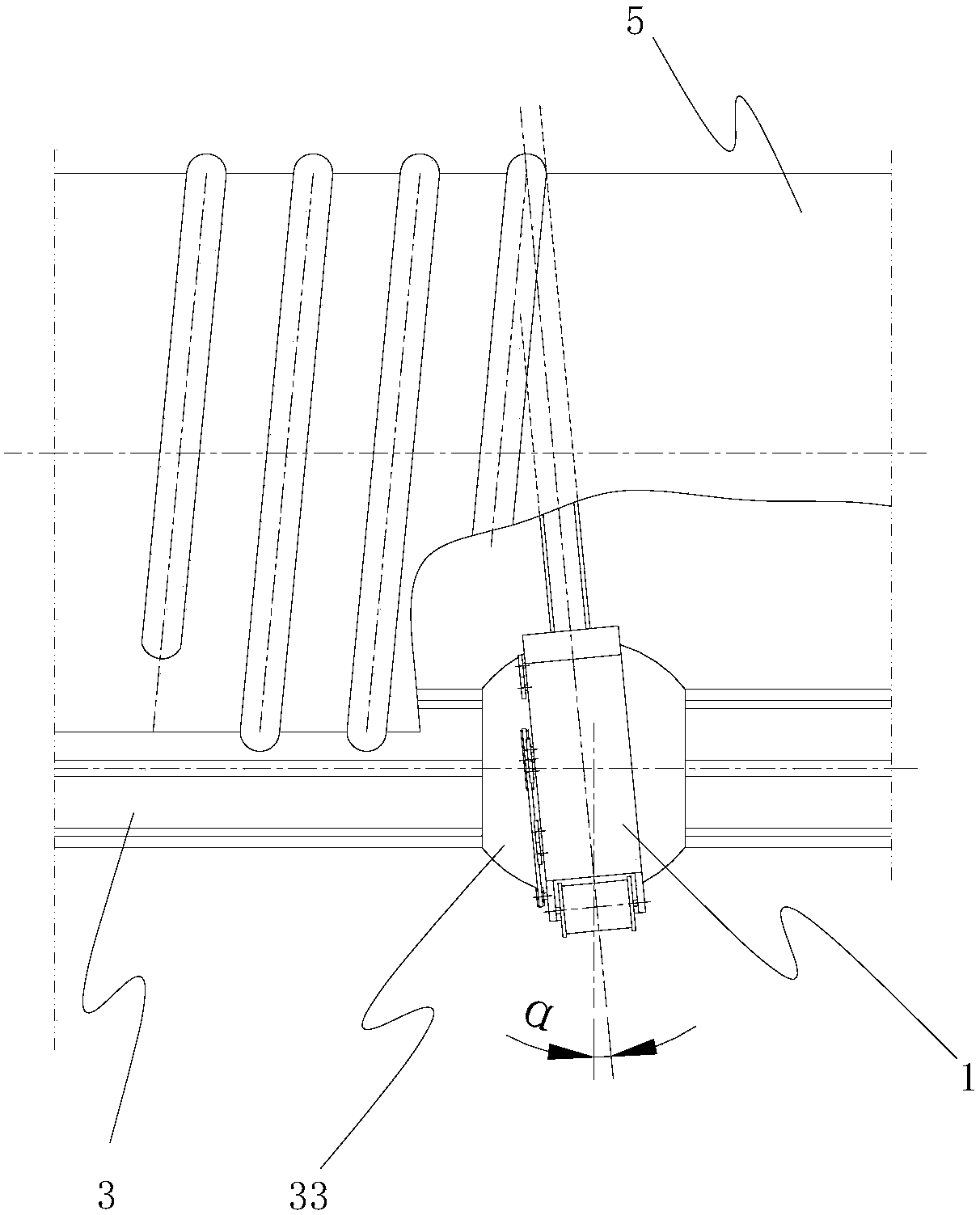

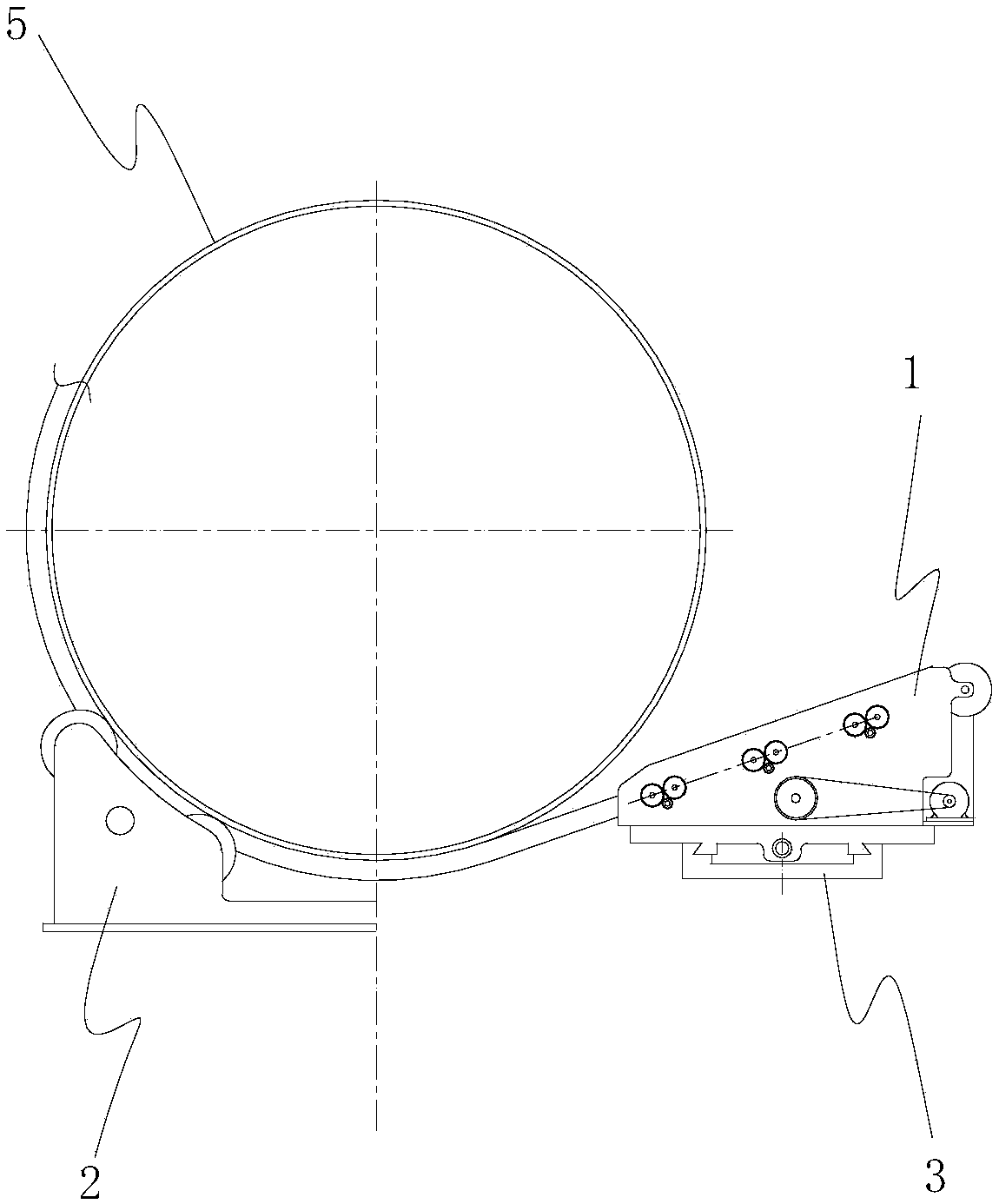

[0030] Such as Figure 1 to Figure 5As shown, a spiral half-pipe automatic winding system in this embodiment includes a half-pipe forming machine 1, a roller frame 2, a half-pipe forming machine walking mechanism 3 and a control system 4, and the half-pipe forming machine 1 passes through the first motor 11 drive, the half-pipe forming machine 1 includes a frame, a steel belt introduction device and a half-pipe forming device composed of a concave wheel and a cam that cooperate with each other. The concave wheel and the cam of the half-pipe forming device are respectively driven by the concave wheel drive shaft and the cam The shaft is fixed on the frame, and the size of the concave wheel and the cam can be replaced, and the position of the concave wheel and the cam can be moved. The bending radius of the spiral half pipe and the specification of the half pipe can be adjusted at any time. The operation is convenient. At least one concave wheel is connected with the first motor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com